An overheating engine is a serious problem in off-road machinery. When you spot that the cause is a failing radiator, it’s highly recommended to replace it directly rather than repair it, as the cost of replacement is much less than the costly downtime. For a full replacement cost, it varies depending on the type, replacement parts, regional labor cost, and more. Typically, a replacement cost ranges from $800-$7,000+. This guide will show you why it varies a lot, learn now.

Of course, if you are confident and experienced, you can also follow the DIY guide to replace it yourself.

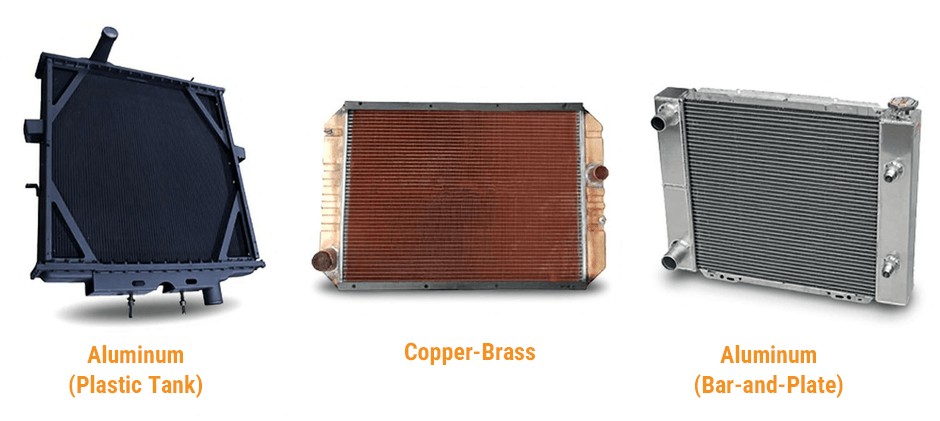

Radiator Type & Replacement Cost

The cost to replace a radiator on heavy machinery is primarily driven by its construction and the size of the machine. The estimated full replacement costs in the table below provide a general range that includes both the part and typical labor fees. Labor costs for replacement typically range from $300 to $800+, depending on the machine’s complexity and accessibility.

| Radiator Type | Primary Construction | Estimated Full Replacement Cost |

|---|---|---|

| Aluminum (Plastic Tank) | Lightweight aluminum core with crimped-on plastic end tanks. | $800 – $2,200 |

| Copper-Brass | Traditional heavy copper tubes and brass fins, all soldered. | $1,500 – $3,500 |

| Aluminum (Bar-and-Plate) | Heavy-duty, fully welded, all-aluminum construction. | $3,000 – $7,000+ |

Why the Three Radiator Replacement Costs Are So Different

The significant price gap between these radiator types comes down to two factors: raw material cost and the complexity of the manufacturing process.

Aluminum (Plastic Tank): The Economy Choice

This is the least expensive design because it uses the cheapest materials and a highly automated manufacturing process. The aluminum core is lightweight, and the plastic tanks are mass-produced and simply crimped onto the core with a gasket. This low-cost, low-labor method results in an affordable but non-repairable radiator where the plastic and crimp-joint are the most common failure points.

Copper-Brass: The Traditional Standard

The mid-range cost of this type is due to higher material costs—copper and brass are significantly more expensive commodities than aluminum. The manufacturing process is also more labor-intensive, requiring skilled technicians to solder the tubes, fins, and headers together. This results in a heavier, more expensive, but often repairable radiator.

Aluminum (Bar-and-Plate): The Heavy-Duty Champion

This is the most expensive option due to its extremely robust, labor-intensive construction. While it uses aluminum, it uses much more of it in thick, durable bars and plates. More importantly, it is a fully welded unit. TIG welding aluminum to create a pressure-tight vessel that can withstand intense vibration and impacts is a highly skilled, time-consuming process. This specialized labor is the primary driver of its premium cost, resulting in the most durable and reliable radiator available.

Additional Factors That Influence Your Total Cost

The price of the radiator itself is only part of the equation. Several other factors can significantly impact your final invoice.

Machine Size and Class

The cost is not one-size-fits-all. A radiator for a 3-ton mini excavator will be far less expensive than one for a 40-ton articulated dump truck or a large dozer.

Labor Rates and Location

- OEM dealer labor rates are typically the highest ($150 – $250+ per hour).

- Independent heavy equipment repair shops offer more competitive rates ($90 – $160 per hour), but ensure they have experience with your specific machine.

Component Accessibility

- On many modern machines, the radiator is part of a “stacked” cooling package, sitting behind the hydraulic oil cooler and A/C condenser.

- If other coolers must be removed to access the radiator, your labor time and costs will increase substantially.

Associated Parts Replacement

To ensure system reliability and prevent a second failure, it is highly recommended to replace related components at the same time. Budget for:

- Radiator Hoses: The radiator hose replacement cost is a small but mandatory part of the job. Both upper and lower hoses must be replaced. The upper radiator hose replacement cost is particularly important to factor in, as this hose often endures the most heat and stress.

- Thermostat: A cheap but critical part. It’s foolish not to replace it while the system is drained.

- New Coolant: The system must be refilled with the manufacturer-specified coolant.

- Hose Clamps: Old clamps can lose tension and cause leaks.

- Radiator Cap: The radiator cap replacement cost is minimal—often under $50—making it a foolish part to reuse. An old, faulty cap can’t maintain pressure, which will cause the new radiator to overheat. Always include this in your budget. You can also learn the difference between a radiator cap and a coolant cap to ensure you get the right one.

- Radiator Fan: While the radiator is out, it’s the perfect time to inspect the radiator fan for cracked blades or a worn clutch (if applicable). If damage is found, the radiator fan replacement cost will need to be added to your total, but it’s much cheaper to do it now than to pay for separate labor later.

When Do You Need to Replace the Radiator

While any coolant leak is a concern, certain failures are terminal. Attempting to repair them is often a waste of money that will lead to a second, more costly downtime event.

Universal Signs of Replacement

- Major Physical Damage: The radiator’s frame is bent from an impact, or multiple core tubes are punctured.

- Severe Internal Blockage: The engine consistently overheats despite a clean exterior and functional fan. This indicates internal channels are clogged with scale or sludge that flushing cannot remove.

Specific Signs of Replacement

- Aluminum Radiators with Plastic Tanks: A crack, no matter how small, in one of the plastic end tanks. This is the most common failure mode and is non-repairable.

- Copper-Brass Radiators: Multiple leaks appearing in different spots over a short period. This signals that the solder joints throughout the core are failing from age.

- Bar-and-Plate Radiators: A crack along a major weld seam. The specialized labor required to properly repair a structural weld often makes replacement a more cost-effective and reliable option.

Parts Cost Comparison: OEM vs. FridayParts

You don’t have to pay a premium for reliability. High-quality aftermarket parts offer a strategic advantage.

OEM Parts

- Cost: The highest price point, as you are paying for the machine’s brand name.

- Availability: Can be subject to dealer stock levels and potential backorders, extending downtime.

FridayParts Aftermarket Parts

- Cost: Significant savings, often 30-60% less than the OEM equivalent.

- Quality: Manufactured to meet or exceed OEM specifications for fit, cooling performance, and durability.

- Availability: Held in stock and ready for immediate shipment, drastically reducing your machine’s downtime.

Conclusion

The radiator replacement cost is high, but you must replace it promptly, avoiding further damage, which can cost you even more. What’s more, although you can neither change the labor cost nor replace it yourself, you can save the parts cost by choosing FridayParts. As a reliable and renowned off-road machinery parts supplier, we stock a wide selection of OEM-quality aftermarket radiators for Doosan, DEVELON, Caterpillar, Komatsu, and more. Explore our full catalog and buy the right radiator for your partner right now!

For further maintenance and preventative tips, you can read the 7 Must-Know Radiator Maintenance Tips.

Here are more replacement cost guides for the fuel filter, thermostat, blower motor, air filter, fuel pump, fuel injector, EGR cooler, AC compressor, and water pump.