One of the most frequently asked questions we hear in the maintenance of off-road equipment is “How much does it actually cost to replace an air filter?” Generally, the cost of replacing a filter varies, and the current price range for air filter replacement in 2025 is $10-300+. If you choose to do the repair yourself, your overall air filter cost can be reduced by about $30 to $170.

In this article, we’ll break down the replacement costs and warning signs of a bad air filter. Also, we share factors that influence the price, compare DIY vs. pro costs, and discuss whether DIY replacement is a viable option.

Key 2025 Cost Highlights

For those who need the numbers upfront, here’s a quick look at what you can expect to pay for air filter replacements.

| Service | Part Cost (High-Quality Aftermarket) | Professional Installation (Total Cost) |

|---|---|---|

| Engine Air Filter Replacement | $20 – $150+ | $55 – $315+ |

| Cabin Air Filter Replacement | $10 – $100+ | $40 – $230+ |

These are general estimates. The final cost depends heavily on your specific machine and local labor rates.

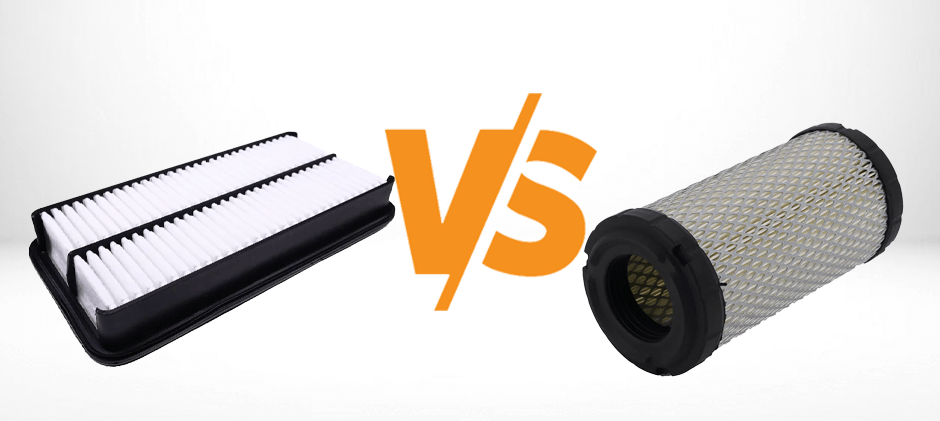

Different Types of Air Filters Cost

The air filter replacement cost differs greatly between the engine and cabin filters. Let’s look at each one individually.

Engine Air Filter Replacement Cost

The engine air filter’s job is to prevent dirt, dust, and debris from being sucked into the engine’s combustion chamber. It is large, complex, and critical to the operation of your machine. Allowing this filter to become clogged is a mistake that can cost you thousands in engine repairs. You’ll start to notice a loss of power, reduced fuel economy, and other signs of a bad engine air filter.

In 2025, replacing an engine air filter for heavy equipment typically costs $20 to $150 for a high-quality aftermarket part. If you do it yourself, that’s usually all you’ll pay. However, if you go to a professional, the total cost with labor can range from $55 to over $315, depending on the machine’s size and complexity.

Cabin Air Filter Replacement Cost

The cabin air filter cleans the air that comes into the cabin through the HVAC system, removing dust, pollen, mold spores, and other pollutants. The cabin air filter replacement cost is generally more affordable. However, its importance cannot be overstated, especially for operators with allergies or those working in extremely dusty conditions. When choosing a replacement, it’s a good idea to research the best cabin air filter for your specific environment, as some offer features like activated carbon for odor removal.

In 2025, replacing a cabin air filter typically costs $10 to $100 for a quality aftermarket part. If you replace a cabin air filter by yourself, that’s usually all you’ll spend. Professional installation can raise the total to $40 to $230 or more, especially if the filter is hard to access. Many operators choose to DIY and save on labor.

Air Filter Replacement Cost Factors

- Machine Type and Size: This is the biggest driver. A massive bulldozer engine needs a much larger and more robust filter than a compact tractor. The bigger the engine, the higher the volume of air it needs, and the more the filter will cost.

- Filter Quality (OEM vs. Aftermarket): Filters from the Original Equipment Manufacturer (OEM) are sold through dealers and carry the highest price tag. A high-quality aftermarket filter can offer the same level of protection and fit for a significantly lower price.

- Labor Costs and Accessibility: Heavy equipment mechanic labor rates typically run from $100 to $200 per hour. An easy-to-access engine air filter might take 15 minutes to change, while a cabin filter hidden deep in the dashboard could take over an hour.

- Operating Environment: If you work in an extremely dusty environment like a quarry or on a demolition site, you will need to replace your filters more frequently, increasing your annual maintenance costs.

Additional Costs to Consider

When calculating your air filter replacement costs, consider the additional costs that may be incurred. These may be discovered when you inspect the air filter and may increase the cost. It is best to do the following before replacing the filter to check your system to account for the additional costs.

- Air Filter Housing: Dirt tends to accumulate inside the housing. Wiping it clean ensures a good seal for the new filter. Minor damage can be replaced selectively. Aftermarket prices range from $30 to several hundred.

- Hoses and Clamps: Check the air intake hose for cracks or loose clamps, which may allow unfiltered air to leak into the engine. If damaged, replace it at the same time

- Check the Filter Minder: Many machines have a filter minder gauge that tells you when the filter is restricted. Make sure it’s working correctly. But once it is damaged, it will give you a false filter signal. If it is found to be damaged, it must be replaced.

Is It Worth Replacing a Bad Air Filter?

The answer to the question is affirmative and definite. Thinking of this as an optional expense is a critical mistake. The cost of a new filter is tiny compared to the cost of not replacing a bad one.

For the engine, a clogged filter starves it of air, leading to:

- Higher Fuel Burn: The engine works harder and burns more fuel to get the same power, costing you money every hour.

- Premature Engine Wear: Unfiltered, dirty air is like sandpaper to your engine’s internal parts. It accelerates wear on pistons, rings, and cylinder walls.

- Catastrophic Failure: In the worst-case scenario, a torn or failing filter can let in a large piece of debris, leading to thousands of dollars in engine repair bills and days of downtime.

For the cabin, the cost of a bad filter is measured in operator health. Breathing in dust and contaminants all day can lead to respiratory issues, allergies, and fatigue, hurting both well-being and productivity. The price of a new filter is truly a small investment in your machine’s health and your own.

When Do You Need an Air Filter Replacement?

Knowing when to replace a filter is just as important as knowing the cost. While the price is a budget consideration, the timing is a maintenance necessity. Here are the key indicators that it’s time for a change:

- Follow the Manufacturer’s Schedule: Your machine’s service manual is the best place to start. Generally, it is recommended to replace the engine filter every 12,000 to 15,000 miles or once a year. For the cabin filter of the HVAC system, it is recommended to replace it at least every 3 months, depending on the climate and usage.

- Check the Filter Minder: Most heavy equipment has a filter restriction indicator or “minder.” This simple gauge tells you how much airflow is being restricted. When the indicator reaches the red zone, it’s time for a replacement.

- Visual Inspection: Sometimes, the simplest check is the most effective. A new filter is typically white or off-white. A used filter that needs replacing will be dark gray or black, visibly clogged with dirt and debris.

- Noticeable Performance Drops: Your machine will often tell you when it’s struggling for air. The classic signs of a bad engine air filter include a loss of power, sluggish throttle response, increased fuel consumption, or black smoke from the exhaust.

- Job Site Conditions: This is the most critical factor for us in the field. The manufacturer’s schedule is based on average conditions. If you work in an extremely dusty environment like a quarry, farm, or demolition site, you must shorten that interval significantly. In these conditions, you may need to check your filter weekly or even daily.

Why Consider Aftermarket Parts?

At least thousands of customers have shared their aftermarket parts experiences with us, and more than 80 % of them indicate that switching from original parts to reputable aftermarket brands can bring huge benefits. Here’s an example of one such feedback: “We used to buy all our filters from the dealer, paying top dollar because we thought it was the only way to guarantee quality. A few years ago, we switched to a trusted aftermarket supplier. Our filter costs dropped by 40%, and we’ve seen zero difference in performance or engine health. Those savings go directly back into our business.”

This real feedback from our customers tells us that the most effective way to manage air filter replacement costs is to switch from original equipment parts to a reputable aftermarket supplier. Great aftermarket brands engineer their filters to meet or exceed OEM specifications for fit, function, and filtration efficiency. You get the same performance and peace of mind without paying the dealer brand premium.

Conclusion

The air filter replacement cost is a fundamental part of any heavy machinery maintenance budget. For 2025, you can expect to pay anywhere from $10 for a simple cabin air filter to over $300 for a complex engine filter on large equipment. By understanding the cost factors and opting to do the work yourself when possible, you can manage these expenses. However, the smartest financial move is to partner with a quality aftermarket supplier to get reliable parts at a fair price.

At FridayParts.com, we are a leading aftermarket parts supplier dedicated to helping you keep your equipment running without overpaying. We offer a massive inventory of high-quality engine and cabin air filters for a wide variety of heavy equipment brands, all at affordable prices. Don’t choose between a healthy machine and a healthy bud