What is a hydraulic gear pump? A hydraulic gear pump is the heart of many heavy machines, responsible for generating the hydraulic pressure needed to power various components. Whether in excavators, loaders, or tractors, this pump ensures smooth operations by delivering pressurized hydraulic fluid where it’s needed. If you are wondering if there is something wrong with your hydraulic pump, you just came to the right place. The article aims to help you identify signs and causes of hydraulic pump failure early and save your time and money. In this guide, we’ll explore the most common warning signs, discuss troubleshooting methods, and outline key maintenance practices to keep your hydraulic gear pump in top shape.

Unusual Noises (Grinding, Whining, or Knocking)

A healthy hydraulic gear pump should operate with minimal noise. If you start hearing grinding, whining, or knocking sounds, it’s a strong indication that something is wrong. These noises often result from cavitation, a condition where air bubbles form in the hydraulic fluid and collapse under pressure, causing damage to internal components. Air leaks in the system can also introduce unwanted air pockets, leading to erratic fluid movement and excessive noise. Additionally, worn-out gears or bearings inside the pump can cause grinding sounds as metal components rub against each other. If you notice these noises, inspect the system for air leaks, check fluid levels, and replace damaged parts before the issue escalates into a complete breakdown.

Loss of Hydraulic Pressure

A significant drop in hydraulic pressure is another major red flag. When a hydraulic gear pump fails to maintain adequate pressure, the machinery loses its efficiency, leading to weak lifting power and sluggish performance. This issue often stems from internal wear, damaged seals, or hydraulic pressure loss due to fluid contamination. As seals degrade over time, they allow hydraulic fluid to escape, reducing pressure within the system. Contaminated fluid, filled with dirt or debris, can also cause blockages or accelerate internal wear. Regularly checking for leaks, inspecting the condition of seals, and ensuring the hydraulic fluid remains clean can help maintain proper pressure levels and extend the lifespan of the pump.

Slow or Weak System Performance

If your machine begins to move at a sluggish pace, struggles to lift heavy loads, or takes longer to complete routine tasks, the hydraulic gear pump may be the culprit. A loss of efficiency in the pump means that the system isn’t getting the necessary power to operate smoothly. Low hydraulic fluid quality, clogged filters, or worn-out internal components can all contribute to weak performance. When fluid levels are low or contaminated, the pump has to work harder to maintain function, which can lead to overheating and further damage. Checking the hydraulic system for restrictions, replacing dirty filters, and ensuring the pump isn’t overloaded can help restore optimal performance and prevent long-term damage.

Overheating Issues

Excessive heat is a clear sign that your hydraulic gear pump is struggling. Overheating often results from increased friction due to worn-out components, low hydraulic fluid levels, or poor ventilation. When the pump runs at higher temperatures than normal, it accelerates wear on seals, gaskets, and moving parts, leading to premature failure. Insufficient lubrication due to contaminated or inadequate fluid can further worsen the problem, causing parts to grind against each other. Ensuring the system has proper ventilation, maintaining fluid levels, and avoiding overloading the pump can help prevent overheating and improve efficiency. If the pump consistently runs hot, it may be a sign of deeper mechanical issues that require immediate attention.

Leaking Hydraulic Fluid

Leaking hydraulic fluid is not only a sign of pump failure but also a serious hazard that can affect system performance. If you notice puddles forming under your equipment or see fluid seeping around seals, fittings, or the pump housing, it’s a clear indication that the hydraulic gear pump has developed leaks. Over time, seals and gaskets can crack or wear down, leading to fluid loss and pressure drops. Loose or damaged fittings can also contribute to leaks, causing the pump to work harder to compensate for the lost fluid. Regularly inspecting seals, tightening fittings, and addressing leaks promptly can help prevent pressure loss and ensure the hydraulic system functions efficiently.

Causes of Hydraulic Gear Pump Failure

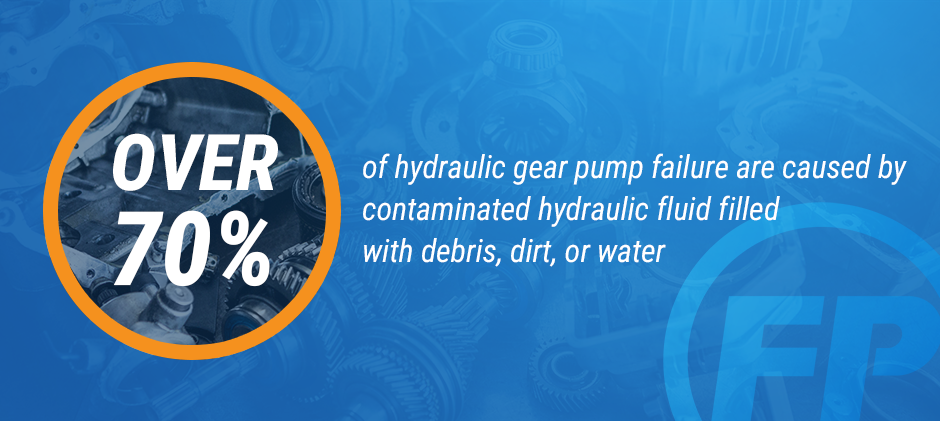

Several factors contribute to hydraulic pump failure, with contamination, excessive workload, and neglect being the most common. Contaminated hydraulic fluid filled with debris, dirt, or water can cause internal damage and accelerate wear on gears and seals. Using the wrong type of hydraulic fluid can also reduce efficiency and increase strain on the system. Overworking the pump beyond its rated capacity leads to excessive wear and overheating, shortening its lifespan. Failing to perform regular hydraulic pump maintenance further exacerbates these problems, allowing minor issues to escalate into complete failures. Addressing these causes early can help extend the pump’s lifespan and improve machinery performance.

Troubleshooting & Preventative Maintenance Tips

To avoid major breakdowns, regular maintenance is crucial. Performing frequent inspections of the hydraulic gear pump, checking for leaks, and ensuring proper hydraulic fluid quality can significantly improve system longevity. Monitoring pressure levels, replacing worn-out components, and ensuring proper ventilation can prevent overheating and efficiency loss. Flushing out contaminated hydraulic fluid and keeping filters clean will help maintain optimal performance. By staying proactive with maintenance, operators can prevent unexpected failures, reduce downtime, and keep their machinery running smoothly.

Conclusion

Whether it’s unusual noises, pressure loss, overheating, or fluid leaks, each warning sign should be addressed promptly to keep your hydraulic gear pump in peak condition. Regular hydraulic pump maintenance, proper fluid management, and timely troubleshooting can help extend the pump’s lifespan and ensure heavy machinery continues to operate efficiently. If you start noticing any of these issues, taking immediate action can prevent further damage and keep your equipment running at full power. Sure you need to replace the gear pump but don’t know where to buy it? FridayParts sells gear pumps at a fair price, and the online shop covers a wide range of brands and models that could meet your needs! Visit FridayParts now to get the best replacement gear pump!