Idler Pulley vs Tensioner Pulley: Are They the Same? There’s no doubt, they are not the same. But what’s the difference? This guide will introduce both components, helping you know them first. And then we will tell you the 4 key differences, ensuring you can differentiate them quickly and easily. Follow this guide carefully, you can not only prevent the unnecessary economic damage, but also find the specific parts rightfully and easily.

Idler Pulley vs Tensioner Pulley: Definition

What is an Idler Pulley?

An idler pulley is a simple, non-adjustable wheel that guides the serpentine belt. For a complete overview of its types and functions, see our Idler Pulley Guide. Its sole purpose is to direct the belt’s path, navigate around obstacles, and improve its contact (or “wrap angle”) with other pulleys to prevent slippage.

What is a Tensioner Pulley?

A tensioner pulley, it belongs to a moving combination, by itself will make a correct degree of tightening force given to the belt, no need for people to always adjust. It ensures the belt stays tight as it stretches over time and experiences changing engine loads, preventing power loss and noise.

Idler Pulley vs Tensioner Pulley: 4 Key Differences You Must Know

Understanding the specific roles and characteristics of each pulley is essential for any technician or DIYer. Here’s a detailed breakdown that clearly separates their differences.

1. Function

This is the most fundamental difference, defining their entire purpose within the system.

- Idler Pulley: Its role is entirely passive. It acts as a simple waypoint or a bridge, guiding the belt along its correct path, routing it around obstacles, and ensuring it makes proper contact with other pulleys. It does not apply force.

- Tensioner Pulley: Its role is active and crucial for system integrity. It uses an internal spring or hydraulic mechanism to exert constant, calculated pressure on the belt. This active force automatically compensates for belt stretch, temperature changes, and varying accessory loads.

2. Design and Components

Their physical construction directly reflects their function.

- Idler Pulley: Features a simple design. It consists of only two core parts: a pulley wheel (made of plastic or steel) and a pressed-in bearing. This unit is mounted to the engine with a single, fixed bolt.

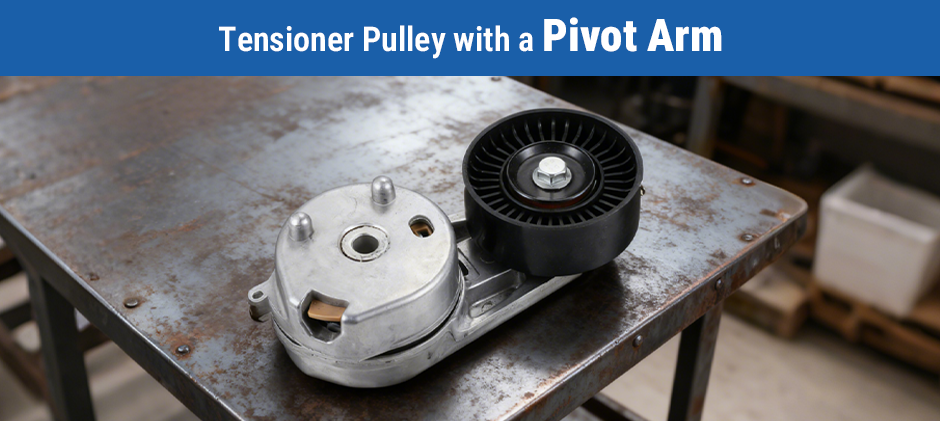

- Tensioner Pulley: Is a complex assembly. It includes the pulley wheel and bearing, but they are mounted on a movable pivot arm. This arm is part of a larger housing that contains the tensioning mechanism (e.g., a powerful coil spring or a hydraulic damper), which provides the controlled force.

3. Failure Modes and Diagnostics

How they fail and the noises they make are distinct diagnostic clues.

Idler Pulley

Failure is almost always localized to the bearing. The primary symptom is a worn-out bearing, which creates a distinct, high-pitched whining or grinding sound that gets louder as the engine RPM increases. You can learn more in our guide to diagnosing a bad idler pulley.

Tensioner Pulley

Can fail in multiple ways, leading to system-wide symptoms.

- Bearing Failure: Produces a whine similar to an idler.

- Weak Spring: Causes insufficient tension, resulting in a loud belt “slapping” noise, chirping, or squealing under load.

- Seized Pivot Arm: Creates excessive tension, which can cause catastrophic failure of expensive components like the alternator or water pump bearings.

4. Adjustment and Mounting

Their mounting determines whether they are stationary or in constant motion.

- Idler Pulley: Is mounted in a fixed, static position. Once bolted on, it does not move or adjust during engine operation.

- Tensioner Pulley: Is designed for constant, dynamic movement. Its pivot arm oscillates back and forth in tiny increments to absorb belt vibrations and maintain steady tension. A healthy, functioning tensioner will exhibit this slight movement when the engine is running.

Idler Pulley vs Tensioner Pulley Comparison

| Feature | Idler Pulley | Tensioner Pulley |

|---|---|---|

| Main Job | Guides the belt’s path | Applies tension to the belt |

| Role | Passive | Active |

| Design | Simple | Complex |

| Mounting | Fixed & Static | Dynamic & Self-Adjusting |

| Common Failure | Bearing noise | Weak tension |

Don’t Let a Failed Pulley Demolish Your Uptime

Differentiating the two important components is the first step to maintaining your investment and increasing your working efficiency. The second is the more important step. You need to find a reliable source that you can trust and depend on. FridayParts is that reputable source.

We offer a wide range of idler pulleys and tensioner pulleys, which are all made from durable materials and undergo rigorous testing to ensure your experience. Whatever you want, FridayParts has you covered. Come and visit our one-stop online shop to explore the whole catalog and more idler components!