The network of belts and pulleys consists of your equipment’s key engine and accessory system. While components like the crankshaft pulley and alternator get a lot of attention, the idler pulley also plays a great role in this system. What is an idler pulley? What Does an Idler Pulley Do? More importantly, how to choose the right type and assembly of an idler pulley? This guide will have you covered.

What is an Idler Pulley?

An idler pulley is a non-powered wheel that is part of a belt drive system. Unlike a drive pulley or a driven pulley, it does not transmit power. Instead, its job is to support and guide the drive belt, performing three essential functions:

- Providing Tension: Its most critical job. It applies constant pressure to the belt to prevent slipping, ensuring consistent power transfer to vital components like the alternator, water pump, and hydraulic pumps.

- Guiding the Belt’s Path: It directs the belt’s path around obstacles within the crowded engine bay, preventing rubbing and premature wear.

- Increasing Wrap Angle: It presses the belt onto other pulleys, increasing the surface area contact for better grip and more efficient power transmission under heavy load.

In short, it’s an auxiliary wheel that ensures the entire belt system operates smoothly and efficiently.

How to Choose the Right Idler Pulley

Choosing the right idler pulley means matching the part to the job. A pulley for a dryer will not survive on an excavator. Here’s a quick guide to understanding the different types based on their application.

Drive Belt

This is the heavy-hitter, designed for the main engine belt system.

- Applications: Excavators, tractors, wheel loaders, and other off-road machinery.

- Key Characteristics: Built for extreme tension and heat. Look for solid steel construction and high-load, sealed bearings to protect against dust and moisture.

Lawn Mower

This is a lighter-duty version used in outdoor power equipment.

- Applications: Riding mowers and garden tractors, for tensioning blade and drive belts.

- Key Characteristics: Lighter construction, often using stamped steel or composite plastic. It is designed for lower horsepower and cannot be substituted for heavy machinery.

Dryer

This illustrates the same principle in a light-duty household setting.

- Applications: Residential clothes dryers.

- Key Characteristics: A small, often plastic part for low-load, low-heat use. It perfectly shows why using an application-specific pulley is essential for reliability.

Grooved vs. Smooth Pulleys: How to Choose

Finally, you must match the pulley surface to the belt:

- Grooved Pulleys: Are for the ribbed side of the belt.

- Smooth Pulleys: Are for the flat, back side of the belt.

Using the wrong type will shred your belt in minutes, so always check the old part before ordering.

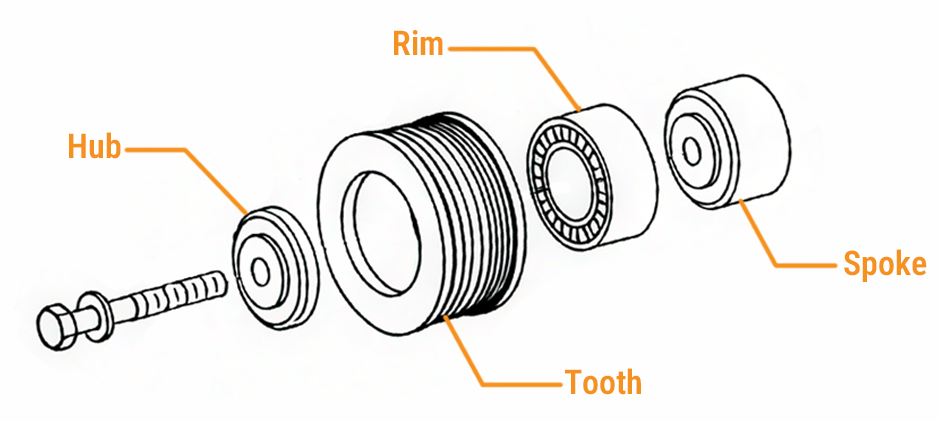

Idler Pulley Diagram

To better understand what it does, let’s look at a typical diagram.

As you can see in the diagram, the pulley is positioned to take up slack in the belt and route it correctly. Its placement is a matter of precise engineering.

Idler Pulley Assembly

Its assembly consists of several key components. Understanding these parts helps in diagnosing problems and making smart purchasing decisions.

- The Pulley Wheel: Can be smooth or grooved.

- Bearing: The heart, allowing it to spin freely.

- Bolt: Secures the assembly to the engine.

- Bushing or Spacer: Ensures correct alignment.

- Tensioner Arm and Spring (in a Tensioner Assembly): Automatically adjusts belt tension. Automatically adjusts belt tension. Many people wonder about the idler pulley vs the tensioner pulley; the key difference is that the tensioner is a complete assembly with a spring-loaded arm, while an idler pulley is just the wheel itself.

How to Choose an Idler Pulley Assembly

When selecting an assembly, keep in mind:

Automatic vs. Manual Tensioning

- Automatic assemblies use a spring arm to adjust belt tension automatically—best for modern machines.

- Fixed idler assemblies require periodic manual belt adjustment—common on older equipment.

Load & Vibration Resistance

- Choose assemblies built for heavy-duty applications if you’re working with large excavators, tractors, or loaders.

Ease of Replacement

- Some assemblies are bolt-on; others require precise alignment. Match your skill level and maintenance schedule.

OEM vs. Aftermarket Quality

- OEM ensures a perfect fit.

- High-quality aftermarket options (like FridayParts) can deliver equal reliability at a lower cost.

Choose the Right Idler Pulley at FridayParts

From the engine bay to the cutting deck, it proves itself a million times. But a failing pulley isn’t just a squeak—it’s a warning of impending downtime. If you suspect a problem, our bad idler pulley diagnosis guide can help you confirm it. This is where having the right partner matters.

FridayParts stocks a vast range of options, from individual idler pulleys for Caterpillar, John Deere, and Cummins engines to complete pulley kits that include the belts you need for the job. Don’t let a failing pulley sideline your equipment. Find the exact, durable idler pulley & assembly at FridayParts today, and keep your operation running without interruption.