At first, the idler pulley noise could be easily ignored. However, it might be the symptom of a bad idler pulley, which can lead to serious damage without repair or replacement. This guide will tell you how to tell if the idler pulley is bad, 6 signs of a bad idler pulley, and teach you the idler pulley replacement step-by-step guide. For a more general overview, you can also check out our Idler Pulley Guide. Read carefully to diagnose if your pulley has these problems. Learn now! Read carefully to diagnose if your pulley has these problems. Learn now!

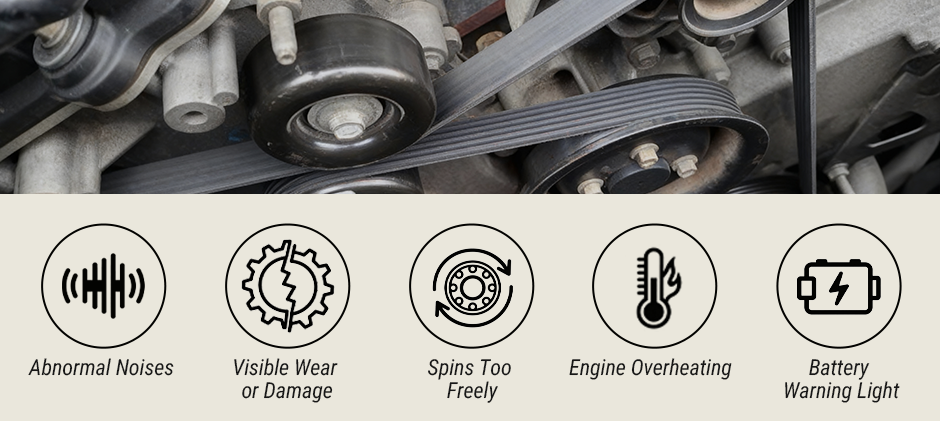

How to Tell if the Idler Pulley is Bad: 5 Common Symptoms

If you suspect a problem with your equipment’s belt system, check for these five classic bad idler pulley symptoms. Catching these signs early can help you prevent a small issue from turning into a major breakdown.

1. Abnormal Noises from the Engine Bay

This is the most common early warning sign. When the idler pulley bearing fails, it will produce several different sounds:

- Squealing or Chirping: A high-pitched, persistent squeal is the classic idler pulley noise. This usually happens when the pulley begins to seize or its surface is worn, causing the belt to rub against it.

- Grinding or Whining: As the bearing deteriorates, the noise can evolve into a rough grinding sound or a whine that rises and falls with engine RPM. This indicates a severe lack of lubrication and imminent failure.

2. Visible Wear or Damage

A visual inspection can reveal many problems. With the engine off, look closely at the pulley system:

- Damaged Pulley: Look for cracks, chips, or severe wear on the pulley’s surface.

- Damaged Belt: Check the belt for signs of wear, frayed edges, or a glazed, shiny surface (caused by slipping).

- Wobbling Pulley: When the engine is running, a bad pulley may visibly wobble instead of spinning smoothly.

3. Spins Too Freely by Hand

The opposite is also a bad sign. A healthy pulley should spin smoothly for a few rotations and then stop. If it spins freely for a long time like a fidget spinner, it means the internal grease has dried up, and failure is imminent.

4. Engine Overheating

This is a severe consequence. If the idler pulley seizes, it can shred the drive belt. A broken belt will cause the water pump to stop working, leading to a rapid rise in engine temperature and overheating. If your temperature gauge suddenly spikes, check your belt and pulleys immediately.

5. Battery Warning Light or Loss of Power Steering

Similarly, a broken belt will stop the alternator from working, triggering the battery warning light on your dashboard. In many cars and machines, the power steering pump is also driven by this same belt drive, so you may also suddenly meet no power steering, making the steering wheel become very heavy, turning up then very hard.

Can a Bad Idler Pulley Cause A Rough Idle?

Yes, a bad idler pulley can indirectly cause a rough idle. As the pulley’s bearing begins to seize, it creates significant drag on the serpentine belt. This additional burden put upon the engine is easy, causing the rotation speed to go up and down when idle time. Furthermore, if the alternator slips because the pulley or tension device is not good, then the alternator may sometimes get a charge, sometimes no charge. This fluctuation in electrical power can confuse the engine’s computer, leading to a rough or unstable idle.

Idler Pulley Replacement Step-by-Step Guide

Replacing an idler pulley is a straightforward job on most machines. While specifics vary, this general guide covers the essential steps.

- Safety First & Gather Tools: Disconnect the machine’s battery. You will typically need a socket set and a long breaker bar or a serpentine belt tool.

- Document the Belt Path: Before you do anything else, take a clear picture of the serpentine belt’s routing around all the pulleys. You will need this to put it back on correctly.

- Release Belt Tension: Locate the belt tensioner. It’s important to understand the difference between an idler pulley vs a tensioner pulley here. The tensioner is the component you will move to loosen the belt. Use a breaker bar or serpentine belt tool to pivot the tensioner and release the tension, then slide the belt off the pulleys.

- Remove the Old Idler Pulley: It is usually held on by a single bolt. Simply unbolt and remove it.

- Install the New Pulley: Install the new idler pulley assembly, making sure any spacers or covers are correctly positioned. Torque the bolt to the manufacturer’s specification to prevent it from coming loose.

- Reinstall the Belt: Make use of your picture or drawing from Step 2, carefully let the belt go again, passing on top of all pulleys one by one.

- Re-apply Tension and Final Check: Slowly release the tensioner to apply pressure to the new belt. Double-check that the belt is correctly seated in every groove on every pulley. Reconnect the battery and start the engine, listening for any abnormal noises.

Idler Pulley Replacement Cost

Replacing an idler pulley involves two costs: parts and labor. The part you choose makes the biggest difference.

Parts Cost: OEM vs. FridayParts

- OEM Dealer Parts: $40–$150 for a pulley, $150–$400+ for a tensioner assembly. You pay a premium for the brand name.

- FridayParts Aftermarket: $15–$70 for a pulley, far less for complete assemblies. Same fit and reliability, without the markup.

Labor Cost

- 1–2 hours of work at $100–$150 per hour → $100–$300 total, whether you buy OEM or aftermarket.

Total Cost Comparison

- OEM Replacement: $140–$700+

- FridayParts Replacement: $115–$370 (and as low as $15–$70 if you DIY)

By switching to FridayParts, you can save 40–60% on most idler pulley repairs while getting parts that meet or exceed OEM specs.

Conclusion

Ignoring the symptoms of a bad idler pulley is the same as taking a gamble. By following this guide, you can find the faulty signs more quickly and easily. And when you define an idler pulley as broken, please repair or replace the worn part as soon as possible.

This is where FridayParts comes in. Compared with the OEM replacement, our product is cost-effective and same quality and reliable. We offer everything from individual pulleys to complete assemblies and kits.

Don’t let a faulty pulley sideline your equipment. Choose FridayParts for OEM-equivalent quality at a competitive aftermarket price, and get your machine back to work quickly and affordably.