Have you ever heard a sharp, unusual noise coming from the engine compartment of your equipment? Many people are puzzled by this strange noise. But in truth, this is caused by the drive belt inside the equipment. The drive belt is specially crafted for power transmission to the critical systems; its damage or aging is very likely to cause unexpected shutdowns of the equipment and costly repair fees, and these costs are usually pricier than the belt itself. This article will lead you to understand information related to the equipment drive belt, explain to you its working principle in the equipment to help you better understand this component, and replace it timely manner when necessary.

What Is A Drive Belt?

Drive belt, commonly called the snake belt or accessory belt, is crafted from a flexible material (usually a durable rubber composite) forming a continuous loop structure, used to transmit power from the engine crankshaft to various accessory components. You may regard it as the transmission system of engine accessories. Without it, those parts that keep the machine engine cooling, the battery charging, and the hydraulic system pressurized will be unable to function properly.

In the non-road machinery field, one drive belt can be responsible for driving several important parts, including:

- Alternator: Generates electricity to charge the battery and to drive the electronic devices of the machine.

- Water pump: Causes the coolant to circulate inside the engine, to prevent it from overheating under heavy duty.

- Cooling fan: Draws air into the radiator to assist the water pump in regulating the engine temperature.

- Hydraulic pump: In some systems, the belt may drive a smaller hydraulic pump to achieve an auxiliary function.

Never mix up the drive belt with the timing belt or timing chain. The timing belt is used to synchronize the internal rotating parts of the engine (crankshaft and camshaft), and it is protected by a cover. If the timing belt fails, it may lead to catastrophic engine damage. Although a drive belt fracture will not damage the internal structure of the engine, it will cause the machine to stop running, and you will be stuck until the drive belt is replaced.

How Does It Work?

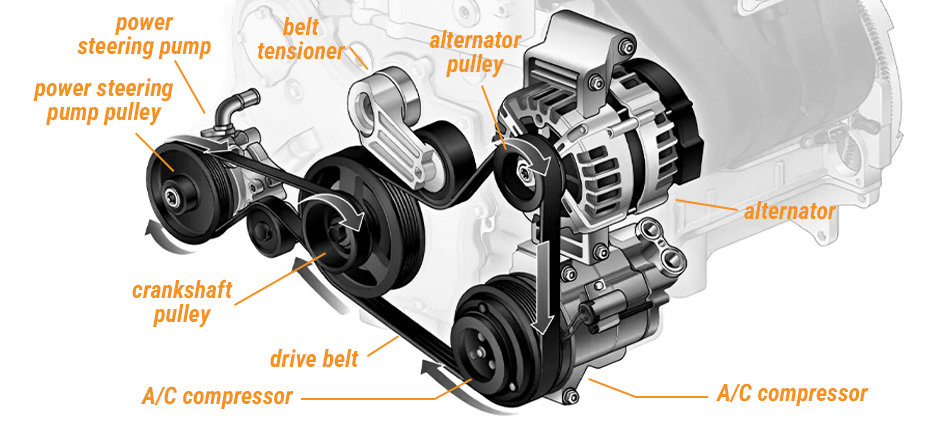

Drive belt system operation is a straightly forward yet mighty example of mechanical engineering founded on friction and tension. The entire procedure relies upon several key components functioning in perfect harmony.

- Power Generation: It all begins at the engine’s crankshaft. As the engine operates, the crankshaft rotates, turning a pulley mounted at its end. This is the “drive” pulley, which supplies all the power for the belt system.

- Power Transfer: The drive belt is wrapped tightly around the crankshaft pulley and a series of other pulleys connected to the accessories (like the alternator and water pump). As the crankshaft pulley turns, the friction between the pulley and the belt causes the belt to move with it.

- Accessory Operation: As the belt circulates, the same friction forces it to grip and turn the pulleys on the other accessories, thereby transferring the engine’s rotational power to them and allowing them to perform their functions.

The core of the entire procedure lies in the tension. If the belt is too loose, it will slip on the pulleys, emit a harsh squealing noise, and fail to transfer power effectively. If the belt is too tight, it will exert excessive stress on the accessory bearings, resulting in premature failure.

At this juncture, the drive belt tensioner finds its utility. The majority of contemporary heavy-duty equipment employs automatic belt tensioners. This is a spring or hydraulic component, furnished with its own separate pulley, capable of perpetually applying the correct pressure to the belt. This arrangement ensures the belt maintains its tautness during its natural processes of stretching and wearing, thereby improving the reliability of the entire system. The health status of the entire assembly, including the individual pulleys on each component, is of critical importance for its effective operation. Collectively, these components constitute one of the most vital belt drive systems of the machine.

Drive Belt Types

Not all drive belts are the same. Depending on your machine’s age and its engine’s demand, you may encounter several different types of drive belts.

- Serpentine Belts: A single serpentine belt drives all accessory components. This is the most common type in modern equipment and vehicles. The belt has multiple grooves, called ribs, on one side that grip the pulleys.

- V-Belts: A set of dedicated V-belts each powers a different accessory component. These older-style belts have a V-shaped cross-section and were more common in vintage equipment. Some older tractors and machinery still use them.

- Timing Belts: Here’s an important distinction – timing belts synchronize the movement of the camshaft and crankshaft to ensure proper engine operation, and failure can cause catastrophic engine damage. Auxiliary drive belts power accessories like the alternator, power steering pump, and air conditioning. A failure will disrupt accessory function but generally won’t damage the engine itself. Don’t confuse drive belts with timing belts – they serve completely different purposes.

| Belt Type | Function | Typical Location | Replacement Urgency |

|---|---|---|---|

| Serpentine/Drive Belt | Powers accessories (alternator, water pump, AC, power steering) | Exterior of the engine, visible | High (prevents operation) |

| V-Belt | Powers a single accessory per belt | Exterior of the engine | High (affects specific system) |

| Timing Belt | Synchronizes engine valves and pistons | Inside the engine, hidden | Critical (can damage the engine) |

At FridayParts, we stock quality belts for various equipment brands and models, so you can get back to work fast.

Drive Belt Maintenance Tips

Proactive maintenance is the best method to prevent sudden belt failure. Please integrate the following simple checks into your regular machine inspection:

- Visual inspection: Carefully inspect all belts. Check for signs of wear such as cracks, glazing (smooth hardened surface), edge wear, or missing rubber blocks.

- Contamination check: Oil and coolant are the enemies of rubber. If you find any liquid leaks dripping onto the belt, please promptly locate and fix the leak source. Contaminated belts will soften, slip, and rapidly fail.

- Audible check: A healthy drive belt runs quietly. If you hear a persistent squeal, chirp, or rubbing noise from the front of the engine, this clearly indicates issues with the belt, pulleys, or tensioner.

- Tension test: Most modern systems include automatic tensioners, but you can still perform a quick check. On the longer, straight section of the belt, you should be able to rotate it only about a quarter to a half turn. If the belt feels too loose or too tight, the tensioner may be faulty.

Signs Your Drive Belt Needs Replacement

One of the earliest warning signs of a bad serpentine belt is a squealing noise. If you hear strange squealing and high-pitched noises, you want to inspect the serpentine belt. The squealing sound comes from misalignment or a worn belt. But that’s just one clue your belt is crying for help.

- Strange Noises: If you hear a whining sound that gets louder and quieter as the engine accelerates up and down, the drive belt may be broken. The whining sound is caused by an overworked auxiliary pulley. Squealing when you first start up is another telltale sign.

- Visual Damage: Pop the hood and take a good look. Cracks, splits, and fraying are visual indicators of a worn belt. If the belt’s sides are glazed over, the belt won’t last much longer. Look for missing chunks, excessive wear on the ribs, or a shiny glazed appearance that means the rubber has hardened.

- Performance Issues: Since the serpentine belt powers the power steering pump and the air conditioning compressor, any issues with these systems could point to a belt problem. If your steering feels stiff or unresponsive, it could be due to a slipping or failing belt. Similarly, if your A/C stops cooling effectively or doesn’t work at all, the belt may not be driving the compressor properly.

- Overheating Engine: Because the drive belt also operates the water pump, an overheating engine is another sign to be wary of. The water pump loses power when the drive belt breaks, and it is unable to pump the water needed to cool the engine. Watch your temperature gauge closely.

- Dashboard Warning Lights: This may trigger the charging system warning light on your dashboard. If you see the battery light or check engine light illuminated, don’t ignore it – your belt might be slipping or failing.

- We can’t stress this enough: The drawback of this single belt is that if the belt breaks or is knocked loose, the vehicle instantly loses multiple critical functions. The water pump, power steering pump, and alternator for battery charging would cease functioning. The vehicle becomes quickly unusable due to the loss of engine cooling.

When Should You Replace It?

Knowing when to perform a drive belt replacement is key to preventing downtime. There are two main guidelines to follow:

Scheduled Intervals: Check your machine’s operator’s manual. Most manufacturers recommend replacing the drive belt at specific service hour intervals, often between 1,000 and 2,000 hours. Clinging to this timetable constitutes the paramount mode of preventive maintenance.

Condition-Based Replacement: Regardless of the hours, you should replace the belt immediately if you observe any of the following signs of failure:

- Multiple cracks across the belt’s surface.

- Any signs of fraying or separation of the belt layers.

- A glazed, shiny, or brittle appearance.

- Any contamination from oil, coolant, or other fluids.

Ignoring these signs is a gamble. Replacing the drive belt costs far less than dealing with an overheated machine, a dead battery on a remote job site, or the damage a snapping belt causes to other components in the engine bay.

FAQs

Can I operate my machine with a broken drive belt?

Cannot. The engine may start, but the water pump and alternator, such an important system cannot working. The engine will overheating in a few minutes, battery is also no charging. Operating the machine in this condition will cause very serious engine damage.

Why heavy equipment transmission belt break?

The most common cause is aging, improper tension not proper (tensioner problem), pulley not aligned, or fluid leakage, make pollution. Rough off-road working environment with big vibration, also causing wear.

How long does a drive belt usually last on heavy machinery?

It depends on the machine and its working condition, but usually life is between 1,000 to 2,000 working hours. Must follow the manufacturer’s suggestion.

Is the drive belt replacement cost expensive?

The belt itself is a relatively low-priced part. If you are asking a mechanic to repair, the total cost will depend on the labor charge. But this kind of prevention cost is much cheaper than handling a breakdown on the job site.

Wrapping It Up

The inconspicuous drive belt is the real powerhouse inside heavy equipment engines. It quietly and reliably performs its key functions, yet it is not permanently durable. Through regular checks and proactive replacement, you can ensure this simple component never becomes the cause of serious trouble. When replacement is needed, sourcing parts from a trusted supplier is crucial. At FridayParts, we offer a large selection of high-quality, affordable aftermarket transmission parts and belt components, ensuring you can rapidly restore machine operation without exceeding budget.