If your battery warning light is glowing, your headlights dim at idle, or your engine struggles to start, you might not have a battery problem at all. The real culprit could be your alternator, the component responsible for keeping your battery charged and your vehicle’s electrical system running.

The good news: you don’t need expensive tools or special training to find out. In this guide, you’ll learn how to check it with a multimeter safely, accurately, and like a pro.

Safety Warning

You may have heard the old-school advice: “Start the engine and pull the negative cable — if it dies, the alternator is bad.”

Never Disconnect the Battery While the Engine Is Running

Here’s why:

- The battery acts as a voltage stabilizer for your entire electrical system.

- Disconnecting it while running causes a dangerous voltage surge that can exceed 100 volts.

- That surge can instantly destroy your ECU, transmission module, radio, and even the alternator itself.

Always use a multimeter to measure voltage instead.

This modern, safe method protects your electronics and provides a precise reading of your alternator’s health.

Pre-Test Checks

Before diving into a full alternator test using a multimeter, do a quick visual and physical inspection. Often, what appears to be a failure is actually a belt or terminal issue.

1. Check the serpentine belt

- Ensure it’s not loose, cracked, or glossy. A slipping belt prevents the alternator from spinning fast enough to charge properly.

2. Inspect battery terminals

- Clean off any white or blue corrosion with a wire brush.

- Make sure clamps are tight and making solid contact.

3. Verify the battery’s age and charge level

- Older batteries (4+ years) may not hold a charge well, even if they are fine.

Once everything looks good, it’s time to perform the three main alternator tests.

The 3-Step Alternator Health Check

Start by setting your digital multimeter to DC Voltage (V⎓) in the 20V range.

Step 1: The Static Voltage Test

Purpose: Ensures your battery is capable of holding a charge before you test it.

How to test:

1. With the engine off for at least 30 minutes, connect:

- Red probe → positive (+) terminal

- Black probe → negative (–) terminal

2. Note the voltage reading.

| Voltage Reading | Battery Condition |

|---|---|

| 12.6 V or above | Fully charged, healthy battery |

| ~12.4 V | 75% charged (good condition) |

| 12.0–12.2 V | Low — recharge before testing |

| Below 12.0 V | Weak or damaged battery |

If the voltage is below 12.4 V, charge the battery first. A weak battery can make a good alternator look bad.

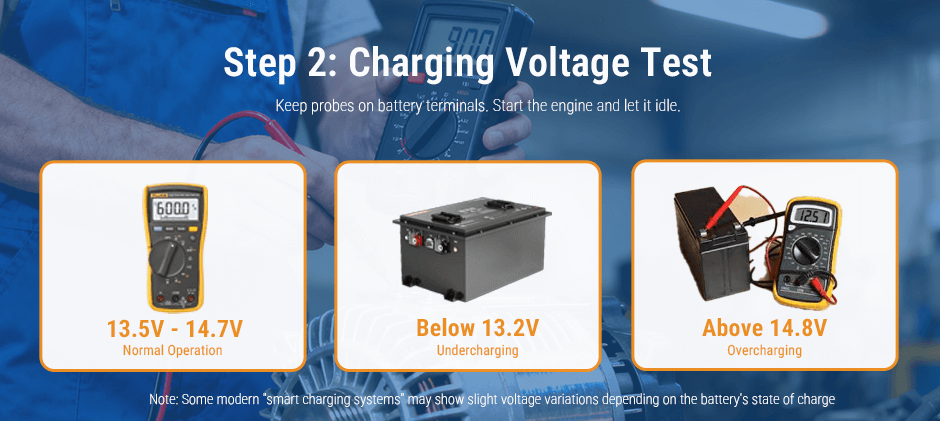

Step 2: The Charging Voltage Test

This step measures how well your alternator charges the battery and powers the electrical system.

How to test:

- Keep the multimeter probes on the battery terminals.

- Start the engine and let it idle.

Observe the voltage change:

| Voltage Reading | Interpretation |

|---|---|

| 13.5–14.7 V | The alternator is working normally. |

| Below 13.2 V | Alternator not charging battery properly. |

| Above 14.8 V | Voltage regulator failed — overcharging. |

Some modern “smart charging systems” may show slight voltage variations depending on the battery’s state of charge.

Step 3: The Load Test

Purpose: To simulate real-world electrical demand and see if your alternator keeps up.

How to test:

1. With the engine running and the multimeter still attached, switch on:

- Headlights (high beam)

- A/C or heater on max

- Radio and defroster

2. Watch the voltage again.

| Result | Meaning |

|---|---|

| Above 13.0 V | The alternator is healthy under full load. |

| Below 13.0 V | Weak alternator — struggling to supply enough current. |

If the voltage drops near 12 V, it is nearing failure.

The Advanced Test: Checking for AC Ripple

Every alternator produces alternating current (AC), which its diodes convert to direct current (DC). If one or more diodes fail, some AC “leaks” back — causing flickering lights and strange electronic behavior.

How to check alternator diodes with a multimeter:

- Keep the engine running.

- Switch your multimeter to AC Voltage (V~) on its lowest range.

- Measure again across the battery terminals.

| Reading | Result |

|---|---|

| < 0.1 V (100 mV) | Normal ripple — diodes are fine. |

| > 0.5 V (500 mV) | Faulty diode — alternator replacement recommended. |

Putting It All Together

You don’t have to guess what’s wrong anymore. Here’s how to read your combined test results:

| Test Outcome | Likely Problem | Recommendation |

|---|---|---|

| Low charging voltage | Worn brushes / bad alternator | Replace or rebuild the alternator |

| High charging voltage | Faulty voltage regulator | Replace alternator |

| Normal tests, but the battery dies later | Weak battery or parasitic drain | Test for the current draw when off |

| Excessive AC ripple | Bad rectifier diode | Replace alternator |

After these tests, you’ll know whether you truly need a new alternator or just a new belt or battery.

Pro Tips for Alternator Testing

- Let the engine warm up before testing — cold alternators may show slightly higher voltage.

- Perform the load test at idle and 1500 RPM to confirm stability.

- If you’re testing in cold weather, normal voltage can be 0.2–0.3 V higher.

- Always ensure your multimeter leads make solid contact — loose probes give false drops.

Final Thoughts

By learning how to test an alternator with a digital multimeter, you’ve gained one of the most valuable DIY skills in auto maintenance.

With only a few minutes and a $20 tool, you can:

- Confirm your alternator’s health,

- Avoid unnecessary part replacements,

- Prevent electrical failures, and

- Save hundreds in diagnostic fees.

If your readings point to alternator trouble, inspect wiring and fuses first, then consider replacing it or the regulator. But remember — proper testing always beats guessing.