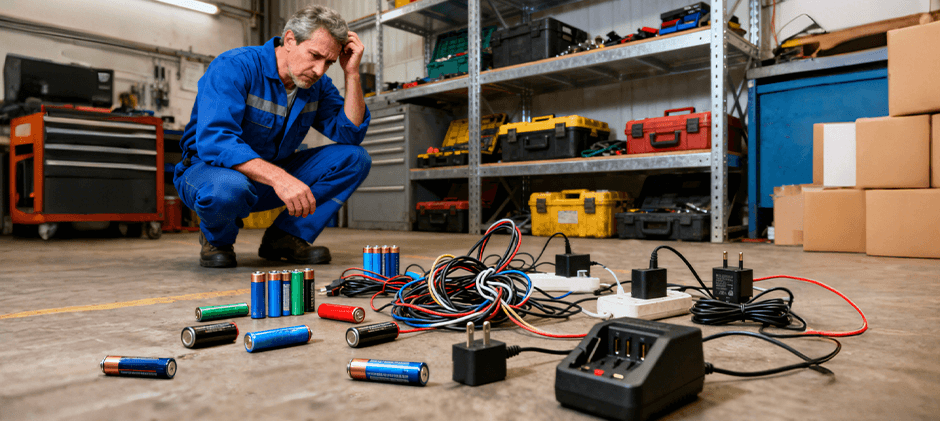

Imagine you are working on the outside while the battery runs out. You grab the spare battery from your tool bag, only to realize it’s not suitable for your tool. Why does this happen? A lack of power tool battery standardization. To prevent this situation, this guide will break down what battery standardization is, why it hasn’t happened yet, and how to solve it.

What is Power Tool Battery Standardization?

In simple terms, power tool battery standardization is the concept of using a single battery type across multiple tools, sometimes even across different brands. Think of it like the USB-C port on modern electronics—one cable and charger for your phone, tablet, and laptop.

In the world of cordless tools, this concept exists on two main levels.

Level 1: Intra-Brand Standardization

This is the most common form of standardization. It means that within a single brand, all tools on the same voltage platform share the same battery. A DeWalt 20V MAX battery will power any tool in DeWalt’s 20V MAX lineup. The same goes for Milwaukee’s M18 platform or Makita’s 18V LXT system. This allows you to buy “bare tools” (without a battery) at a much lower cost.

Level 2: Cross-Brand Standardization

This is the holy grail for users: using one brand’s battery to power another brand’s tool. This is rare, but a few alliances exist, such as the Cordless Alliance System (CAS) in Europe, which unites over 30 brands under a single battery platform.

Why Universal Standardization Fails to Reach

If the technology for advanced, powerful batteries exists, why are we still stuck with this mess? The answer is not technical; it’s a deliberate business strategy built on two types of barriers.

1. Commercial Barriers

The fragmented market is not an accident. It’s a carefully engineered result of strategic business decisions.

- Ecosystem Lock-In: Manufacturers intentionally design incompatible connection interfaces and communication protocols. Once you invest heavily in one brand’s batteries and chargers, the cost of switching to another brand becomes prohibitively high. You are “locked in” to their ecosystem.

- The Profit in Proprietary Batteries: Replacement batteries are a cash cow. They typically have profit margins of 30-40%, compared to just 15-20% on the tools themselves. Manufacturers can sell tools at competitive prices because they know they will make a significant profit on future battery sales. Universal compatibility would destroy this lucrative, recurring revenue stream.

- Valuable Intellectual Property: Modern batteries contain sophisticated Battery Management Systems (BMS) that manage charging, temperature, and power output. This technology is valuable, proprietary intellectual property that represents a competitive advantage. Sharing it would be like giving away a trade secret.

2. Technical Barriers

While the primary reasons are financial, manufacturers often cite legitimate technical challenges as the reason for not standardizing.

- Proprietary Communication: The battery and the tool are in constant communication. The battery’s internal processor tells the tool its charge status, temperature, and power limits, which directly relates to how many amps a power tool uses. This “digital handshake” uses a proprietary language unique to each brand. An incompatible battery simply can’t “talk” to the tool, so for safety, the tool won’t power on.

- Safety and Liability: A power tool battery stores a massive amount of energy. If mismanaged, it can lead to thermal runaway and fire. Manufacturers conduct extensive safety validation on their specific battery-and-tool combinations. They have no data on how their battery will perform with a competitor’s tool, creating a huge liability risk they are unwilling to take.

- The 18V vs. 20V MAX Confusion: This is a perfect example of marketing over engineering. In North America, brands like DeWalt can advertise the battery’s maximum voltage right off the charger (20V), while the nominal operating voltage is 18V. In Europe, regulations require them to use the 18V rating. The batteries are identical 5-cell packs. This marketing-driven difference creates another perceived barrier to standardization.

Why Power Tool Battery Standardization Matters

This lack of standardization has real-world consequences for your workflow and your wallet.

- Massive Redundant Costs: Professional workshops often maintain three or four separate battery platforms. This requires redundant investments in batteries and chargers, adding an estimated 20-30% to the total cost of a professional tool collection.

- Wasted Time and Space: Your workshop needs dedicated charging stations for each brand, creating clutter and complexity. On a job site, you have to haul multiple chargers and battery types, wasting precious time and space in your service vehicle. It’s also important to know how to clean your dirty power tools to protect this investment.

- Compromised Work Quality: Users often report choosing a suboptimal tool for a job simply because it matches the charged battery they have on hand. Your work is constrained by battery compatibility, not by what tool is best for the task.

FridayParts: Your Solution to the Standardization Challenge

As we’ve seen, true, universal battery standardization across all power tool brands is still more of a dream than a reality. You are often forced to juggle multiple systems or lock yourself into a single brand’s ecosystem. This is where FridayParts changes the game.

Instead of being locked into a single ecosystem, we provide a universal solution. We offer high-quality, reliable electrical components from starters, alternators to batteries, and solenoids, which are designed to be compatible with a wide range of brands.

Stop letting compatibility issues dictate your maintenance schedule and budget. For all your equipment, regardless of the brand painted on the side, trust FridayParts to deliver the parts that fit, perform, and last. Visit us today and standardize your solution.