As the saying goes, “Sharpening the knife makes the chopping of wood easier, and a towering building rises from the ground.” Knowing the electrical units of your power tool is necessary. Amps and power ratings are common points of confusion. Understanding amps and how many amps a typical power tool draws can help you choose the right tool.

This guide will introduce amps, watts, and volts to you. We will also tell you the power consumption of common tools, and give you practical tips to save on your electrical bill.

What Are Amps, Volts, and Watts?

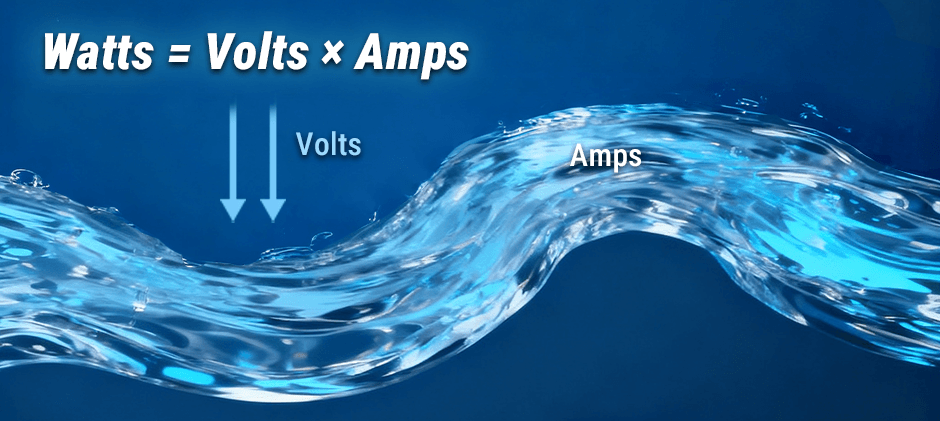

To help you figure out what they are, you can compare electric current to water flow.

- Voltage is the water pressure. It’s the force pushing the electricity through the wire.

- Amps is the volume of water flowing. It’s the rate at which electricity is moving.

- Watts is the total power. It’s the combined effect of pressure and volume.

In short, Amps tell you how much electricity a tool is drawing at any given moment. More amps generally mean more power, but also more heat and energy consumption.

Definitions and Formulas

Amps (A): Measures the rate of electrical current. A higher amp number means more electricity is flowing.

Formula: Amps = Watts ÷ Volts

Volts (V): Measures the electrical potential or “pressure” in a circuit. In the United States, most standard corded tools operate at 120V.

Formula: Volts = Watts ÷ Amps

Watts (W): Measures the total power consumed by a tool. It’s the most direct measurement of energy usage.

Formula: Watts = Volts × Amps

Running Watts: The continuous power a tool consumes during steady operation. This is usually much lower than its starting wattage.

Formula: Running Watts = Running Amps × Volts

What Does “Amp Rating” Mean?

An amp rating on a tool describes the maximum amount of electrical current it is designed to draw safely during operation. Tools with a higher amp rating are intended for more demanding tasks, such as drilling through dense materials or making long cuts with a circular saw.

How Many Amps Does a Typical Power Tool Use?

The amp draw varies widely depending on the tool’s size, motor, and the task it’s performing. A drill will use far fewer amps under no load than when it’s stalled while driving a large screw.

Here is a chart of common corded power tools and their typical amp draw, calculated at a standard 120V.

| Power Tool | Typical Wattage | Amps (at 120V) |

|---|---|---|

| Air Compressor | 2000W | 16.6A |

| Disc Grinder | 2000W | 16.6A |

| Table Saw | 1800W | 15 A |

| Electric Pressure Washer | 1600W | 13.3 A |

| Chop Saw / Miter Saw | 1500W | 12.5 A |

| Heat Gun | 1500W | 12.5 A |

| Electric Lawn Mower | 1440W | 12 A |

| Leaf Blower (Corded) | 1440W | 12 A |

| Circular Saw | 1400W | 11.6 A |

| Electric Chainsaw | 1200W | 10 A |

| Router | 1200W | 10 A |

| Reciprocating Saw | 1100W | 9.2 A |

| Belt Sander | 1000W | 8.3 A |

| Hammer Drill | 960W | 8 A |

| Wet/Dry Vacuum | 888W | 7.4 A |

| Angle Grinder (4.5-inch) | 840W | 7 A |

| Power Drill | 720W | 6 A |

| Orbital Sander | 600W | 5 A |

| Bench Grinder (6-inch) | 480W | 4 A |

| Hedge Trimmer (Corded) | 480W | 4 A |

| Paint Sprayer | 360W | 3 A |

| Oscillating Multi-Tool | 360W | 3 A |

| Jigsaw | 300W | 2.5 A |

Conclusion:

- Small Portable Tools: 2 to 8 amps

- Larger Power Tools: 6 to 16 amps

- Cordless Tools: These are different. An 18V cordless drill can draw over 30 amps from the battery when stalled, but much less during normal use. Their power is often compared to corded tools; a cordless tool might have half the wattage of its corded equivalent.

Is It Safe to Use High-Amp Tools?

Yes, but with caution. Tools with higher amp ratings can pose a safety hazard if not used correctly. Ensure your workshop’s circuit breaker is rated appropriately for the tool (a 15-amp tool should not be run on a circuit shared with many other devices). Overloading a circuit can cause it to trip, or worse, create a fire hazard.

Always wear protective gear and follow proper maintenance procedures to ensure both safety and tool durability.

4 Tips to Save on Your Electrical Bill

Understanding amps and watts isn’t just for safety—it can also help you save money. Here’s how to manage power consumption and reduce your electricity bills.

- Maintain Your Tools. A clean, well-lubricated tool runs with less friction, which means it uses less electricity to do the same amount of work. Regularly clean air vents and sharpen blades.

- Use the Right Tool for the Job. Using an underpowered tool for a heavy-duty task strains the motor and wastes energy. Conversely, using a massive tool for a small job is inefficient. Match the tool to the task.

- Operate at Optimal Speeds. More speed isn’t always better. Running a tool faster than necessary can waste electricity without improving the result. Let the tool work at its intended pace.

- Manage Your Batteries. For the no-wire tools, you should use one kind of smart charger, which can stop the over-charging, because that is making the battery life shorter, and also wasting electricity. When the charger is not in use, better to pull out the plug, so you can avoid the ghost-like power sucking.

Final Thoughts

As we mentioned in our tips, proper tool maintenance is one of the best ways to save on your electrical bill. A faulty component forces the motor to work harder, drawing more amps and wasting energy. Over time, this not only increases your electricity bills but also leads to serious tool failure.

A high-performance tool is only as strong as its weakest component. Instead of letting an inefficient tool drain your power and budget, restore it to peak condition with OEM-quality parts from FridayParts. Whatever you need, our extensive stocks can get your equipment running like new.

Explore our full range of power tool parts for all major brands. Restore your tool’s performance, save on energy, and enjoy fast, global shipping with FridayParts!