DPF vs DEF are both important on many newer diesel machines, but they are not the same thing.

One is a filter that catches soot. The other is a liquid that helps clean up exhaust gases. Knowing the difference helps you prevent warnings, power loss, and downtime.

What is a DPF (Diesel Particulate Filter)?

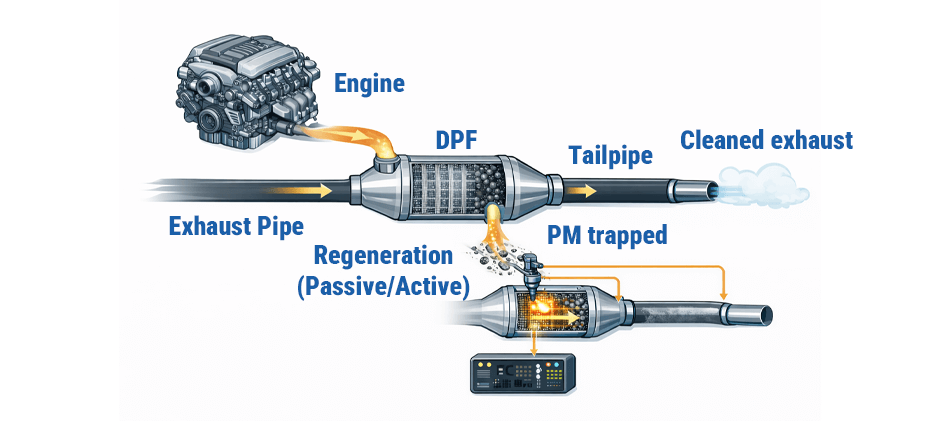

A DPF (Diesel Particulate Filter) is a part of the exhaust system.

Its main job is to catch soot (tiny black particles) made by diesel engines.

Think of it like a “soot net” in the exhaust. It helps stop black smoke from going out the tailpipe.

How Does a DPF Work?

As the machine runs, soot fills the DPF. To clean itself, the machine does a process called regeneration (regen).

During regen, the ECU (computer) raises exhaust temperature very high (often over 1,000°F / 550°C) so the soot burns off. After regen, only a small amount of ash is left behind.

Over time, ash builds up. Regen cannot remove ash. When ash gets too high, the DPF may need:

- professional cleaning, or

- replacement

Important Statement: If you often stop the machine during regen, or you never let regen finish, the DPF can clog quickly and cause warnings, power loss, or shutdown.

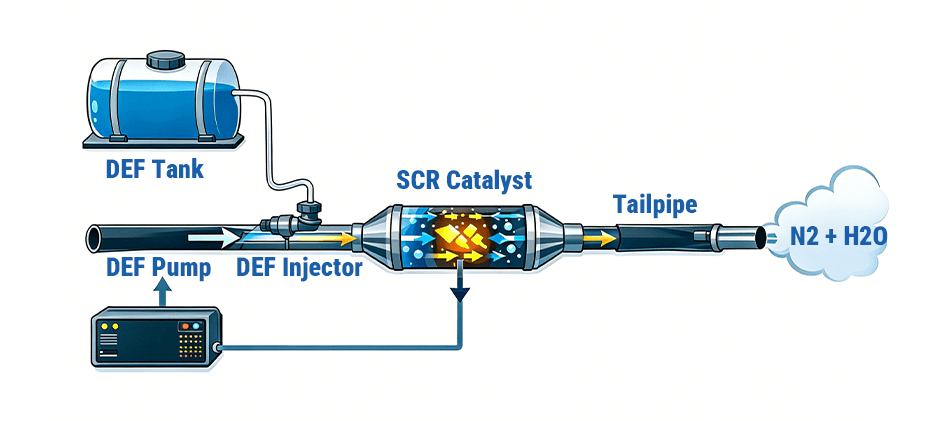

What is DEF (Diesel Exhaust Fluid)?

DEF (Diesel Exhaust Fluid) is a liquid used by the SCR system (Selective Catalytic Reduction).

DEF is usually 32.5% urea and 67.5% deionized water.

Clear Statement: DEF is NOT fuel. You do not mix it with diesel. It goes in its own tank and is injected into the exhaust.

Why Does My Machine Need DEF?

DEF helps the SCR system reduce NOx (Nitrogen Oxides). NOx is an invisible, harmful gas.

Here’s the simple idea:

- The machine sprays a small amount of DEF into the hot exhaust.

- In the SCR catalyst, a chemical reaction happens.

- NOx turns into nitrogen and water vapor (much safer stuff).

DPF vs DEF: What’s the Key Difference?

DPF and DEF solve two different problems. Many machines have both, but they do different jobs.

| Feature | DPF (Diesel Particulate Filter) | DEF (Diesel Exhaust Fluid) & SCR System |

|---|---|---|

| What is it? | A physical part (a filter). | A liquid used by the SCR system. |

| What does it target? | Soot / particulate matter (black smoke). | NOx gases (invisible). |

| What is your job? | Let regen finish. Later, clean or replace the DPF when ash builds up. | Keep the DEF tank filled with clean, correct DEF. |

| What happens if it fails or runs out? | Clogs → high backpressure → power loss → possible shutdown. | Warnings → engine power reduced (derate) → may not restart. |

3 Common Problems and How to Avoid Them

1. Frequent DPF Clogging

Common causes: Too much idling, short run time, or shutting down during regen.

What to do:

- Avoid long idling when you can.

- Let regen finish once it starts.

- When safe and allowed, run the machine at working RPM (not low idle) so the exhaust stays hot enough.

2. DEF Contamination

DEF is easy to ruin. Dirt, fuel, oil, and even tap water can cause problems.

What to do:

- Use clean, dedicated filling tools (funnel/container).

- Keep DEF containers sealed.

- Store DEF out of direct sunlight and extreme heat.

- Do not reuse old bottles that had other fluids in them.

3. Running Out of DEF

This is simple, but it stops jobs fast.

What to do:

- Check DEF level like you check fuel.

- Top off before long days or remote jobs.

- Don’t ignore DEF warnings—derate usually comes next.

In Summary

- DPF catches and burns off soot (solid particles).

- DEF + SCR reduces NOx (harmful gases).

Both help meet emissions rules, and both need basic care. DPF filters soot. DEF helps clean gases.

If you tell us your machine model and what warning you’re seeing (regen light, DPF pressure, DEF quality, derate, etc.), FridayParts can help you list the safest first checks to do before replacing parts, and supply the quality replacement parts you need.