When you’re working against the clock, few things are more frustrating than seeing a “DEF Level Low” alert flashing on your dashboard. On dozers, excavators, or tractors, this warning means your Diesel Exhaust Fluid (DEF) supply is running low — and ignoring it can bring your workday to a halt.

Running out of DEF doesn’t just trigger a warning light — it can force your machine into reduced power mode, or even prevent it from starting altogether. At FridayParts, we understand every hour of downtime costs money. This practical guide explains:

- How to check your DEF fluid level,

- The role of your DEF level sensor, and

- What to do if your DEF is low, overfilled, or still triggering a warning light.

What Is DEF and Why Is It Critical to Your Equipment

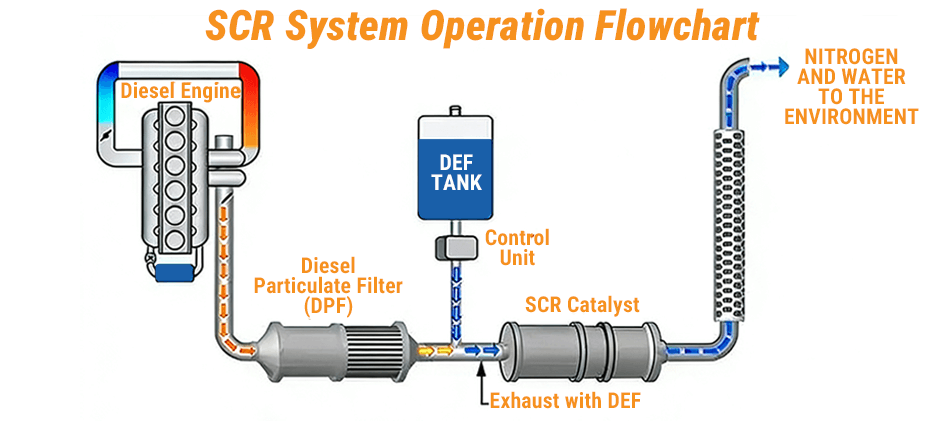

Diesel Exhaust Fluid (DEF) is a precise mixture of 32.5% urea and 67.5% de-ionised water. It’s a vital part of modern diesel engines equipped with a Selective Catalytic Reduction (SCR) system.

When the engine runs, the SCR system injects DEF into the hot exhaust stream. This creates a reaction that converts harmful Nitrogen Oxides (NOx) into harmless nitrogen and water, reducing emissions and keeping your machinery compliant.

Why DEF Matters:

- Regulatory Compliance: Keeps your engine within emissions limits.

- Peak Performance: A low or missing DEF supply triggers power reduction (derate mode) or a no‑start condition.

- Longevity: Proper DEF management prevents costly repairs and ensures clean, efficient combustion.

How Your Machine Monitors DEF: The DEF Level Sensor

Inside your DEF tank lies a sophisticated DEF level sensor, not just a simple float. It constantly provides real‑time data to your engine’s control system.

How It Works:

- Level Measurement: Uses ultrasonic or float‑based detection to measure remaining DEF and update your dashboard gauge.

- Quality Monitoring: Detects urea concentration — if contaminated or diluted, the sensor triggers fault codes.

- Temperature Control: Monitors freezing conditions (around 12 °F / −11 °C) and activates the tank heater as required.

A faulty DEF level sensor may cause false warnings — showing “low” even when the tank is full, or failing to detect poor‑quality fluid. Replacing a failing sensor ensures accuracy and prevents unnecessary downtime.

What to Do When DEF Fluid Level Is Low

Seeing the low‑DEF light is common — but easily fixed. Follow these steps carefully:

- Park on Level Ground: Ensure your machine is parked safely and on level terrain for an accurate reading.

- Use Only High‑Quality DEF: Always choose sealed containers labelled ISO 22241 compliant to avoid contamination from moisture or dust.

- Clean Before Opening: Wipe the area around the blue DEF tank cap. Even small debris can compromise the system.

- Refill Slowly: Use a dedicated DEF funnel and fill gradually until the fluid reaches the indicated “full” line.

- Avoid Overfilling: Leave space at the top — DEF expands by about 7% when frozen, and overfilling can crack the tank.

- Restart and Wait: After refilling and securing the cap, start your engine. The light may take a few minutes or an engine cycle to clear.

What If the DEF Tank Is Overfilled?

DEF overfill can create pressure during freezing conditions, causing cracks in the tank or damage to the sensor.

Here’s What to Do:

- Slight Overfill: Operate the machine for a while to burn off the extra fluid before shutdown in freezing conditions.

- Significant Overfill: Use a clean hand‑siphon pump or dedicated turkey baster to remove excess fluid into a clean container.

Avoid spills on paint or electrical components — DEF can be mildly corrosive over time.

Troubleshooting: DEF Light Still On After Refilling

If the “DEF Level Low” alert persists after refilling, check for these issues:

| Possible Cause | Description | Solution |

|---|---|---|

| Poor DEF Quality | Contaminated or degraded fluid | Drain the tank and refill with fresh DEF |

| Faulty Sensor | The DEF level sensor is malfunctioning | Replace with a quality sensor from FridayParts |

| Clogged Injector or Filter | DEF injection is blocked | Service or replace the injector/filter |

| SCR System Malfunction | Pump, heater, or wiring issue | Diagnose using a diagnostic tool to read fault codes |

Key Takeaways for Busy Operators

- Check Regularly –Include DEF inspection in your daily pre‑start checklist.

- Use Quality DEF – Only ISO 22241‑compliant DEF protects your SCR system.

- Act Quickly – Ignoring DEF warnings leads to derate or shutdown.

- Avoid Overfilling – Leave space for expansion, especially in winter.

- Verify Components – Persistent alerts often trace back to the DEF level sensor or related parts.

Keep Your Machine Running with FridayParts

At FridayParts, we supply high‑quality aftermarket DEF system components, from sensors and pumps to injectors and filters, built for the rugged demands of construction and agricultural machinery.

Explore durable, precision‑fit DEF level sensors and other DEF system parts to eliminate downtime — and keep your equipment performing at its best.