During the operation of heavy-duty equipment, some common electrical or accessory faults usually have a limited impact and are relatively easy to diagnose and fix. In contrast, a powertrain malfunction often involves the engine, transmission or drive system—these problems are more complex and have a greater effect on equipment performance and operational continuity.

What Is a Powertrain System and Why Does It Matter?

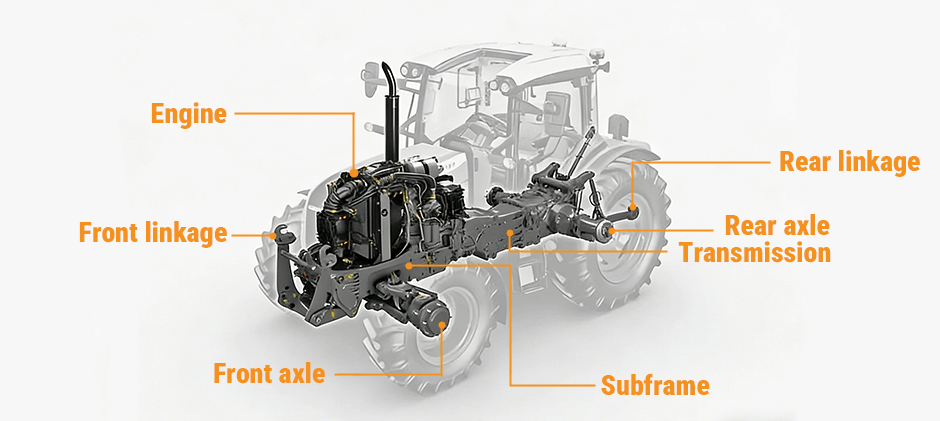

The powertrain is the full set of parts that creates power and sends it to the ground. It’s what makes your machine move, dig, lift, and push. Here are what common powertrain components:

- Engine: Heavy equipment almost always uses a diesel engine. This is where power starts, via internal combustion. It’s the main power source for every other system on the machine.

- Transmission: This part manages the engine’s power. It controls how fast the machine goes and how much pulling force it has. Heavy-duty equipment uses strong transmissions—like hydrostatic or powershift ones. They’re just for heavy-load work.

- Driveshafts and Axles: These are strong metal parts. They move power from the transmission to the final drives or wheels.

- Differentials: These let wheels on the same axle spin at different speeds. That’s key for turning smoothly—no tire scrubbing or axle strain.

- Final Drives: Super important for tracked machines (like excavators and bulldozers). This is a gear unit that steps up the torque one last time to turn the tracks.

- Hydraulic System Link: On most heavy equipment, the engine runs the hydraulic pumps directly. Some people see hydraulics as a separate system. But it depends so much on the engine that how well it works directly affects the whole powertrain’s performance.

What Causes a Powertrain Malfunction?

The machine’s ECM triggers the powertrain fault alert. It controls all the sensors—engine, transmission, hydraulics, and so on. If it picks up something off, it flips on the warning light. The issue could be no big deal, like skipping regular servicing, or a really serious mechanical problem.

Fluid and Lubrication Problems

- Dirty or low engine oil: Engine oil is like the engine’s blood. Skipping oil changes as required leads to poor lubrication. Parts rub together too much, wear out fast, and may even break completely.

- Low or dirty transmission/hydraulic fluid: Overheating and slipping may be because too little fluid. Dust, water or metal shavings mixed into the fluid can damage the clutch, valve and pump, like sandpaper.

- Cooling system: A coolant leak, clogged radiator or broken fan will overheat the engine. The ECM will trigger an alert, and sometimes even cut power to protect the engine.

Sensor and Electrical Failures

Modern machinery relies particularly on electronic systems for its operation. When a sensor fails, it feeds bad info to the ECM. The computer ends up mistaking it for a mechanical issue.

- Speed sensor failure: The input and output speed sensors of the transmission transmit speed information to the ECM. As long as one sensor fails, there may be shifting jerks, jams, or even the machine will not move at all.

- Temperature and pressure sensor failures: These sensors monitor the status of the engine, transmission, and hydraulic system. Sensor failure may falsely report overheating or low pressure, triggering a fault alarm.

- Throttle position sensor failure: This sensor transmits the power requirements required by the operator to the ECM. If it has problems, the engine will respond erratically or lack power.

- Wiring harness damage: Shaking, heat, and general wear can mess up the wiring that connects sensors to the ECM. Sometimes the issue will come and go, other times it’ll be there all the time.

Mechanical Failures

- Fuel system problems: Fuel system issues are super common with diesel engines. If the fuel filter gets plugged up, the engine doesn’t get enough fuel and loses power fast. When fuel injectors go bad, the engine shakes nonstop, uses more fuel, and could even die on you. Water in the fuel is dangerous too—it eats away at parts and ruins the entire fuel system.

- Transmission clutch or brake band wear: In a power shift transmission, shifting is achieved by separating and combining the internal clutches. These parts will wear out over time. At first, they will slip and the power will not keep up. In the end, the machine may not be able to leave.

- Final transmission or axle damage: If the machine hits obstacles such as large rocks or is overloaded for long-term work, the gears and bearings in the final transmission and axle will easily break. At this time, a noticeable friction noise will be heard and the driving force of the machine will decrease.

Symptoms of a Powertrain Malfunction

Your machine usually sends out some early warning signals before it completely fails. Spot the signs early.

- Warning light on: Powertrain malfunction light or Check Engine light on.

- Power loss or slow response: The machine feels sluggish and the engine does not accelerate well. The hills and heavy objects that were easy to climb before will now be obviously difficult to lift.

- Unusual noise: The machine makes a strange noise. Whining noises are generally caused by problems with the hydraulic pump or transmission; grinding noises and clicking noises are often related to the transmission, differential or final transmission.

- Shift problems: The transmission may shift awkwardly, delay, or even get stuck in a certain gear. If it is a hydrostatic system, there may be a jerk when moving forward or backward, or the response may be very slow.

- Overheating: The temperature gauge needle of the engine coolant or hydraulic fluid enters the red area, which is obviously a problem and may also cause power system failure.

- Visible fluid leak: Red (transmission / hydraulic fluid), black (engine oil), or green / orange (coolant) fluid under the machine is an obvious leak and requires immediate attention.

- Excessive smoke or a burnt smell: A burnt smell could be from overheated transmission fluid or leaking oil dripping onto hot exhaust components.

Powertrain Warranty: What’s Covered and What’s Not

When you encounter a large repair fee, your first reaction is definitely to look at the warranty. Most manufacturers have a powertrain warranty. Please figure out the scope. Here’s a general reference that tells you what’s usually covered and what’s not.

| Covered Components | Typical Coverage Period | Column 3 |

|---|---|---|

| Engine Block & Internal Parts (pistons, crankshaft) | 3-5 years / 3,000-5,000 hours | Filters, fluids, belts, hoses |

| Transmission Case & Internal Gears/Clutches | 3-5 years / 3,000-5,000 hours | External coolers, mounts, control modules |

| Final Drives & Axle Assemblies | 3-5 years / 3,000-5,000 hours | Seals, boots, CV joints |

| Transfer Case & Hydraulic Pumps | 3-5 years / 3,000-5,000 hours | Electronic controls, external lines |

One big thing to note: your warranty can be canceled. Skipping the manufacturer’s required maintenance schedule is the main reason this happens. Using the wrong fluids or filters, or modifying the machine in certain ways, can also give the manufacturer a reason to turn down your warranty claim.

Wrapping Up

Know the common causes and symptoms of powertrain failure and perform maintenance before the engine system is damaged. If repairs are unavoidable, knowing your warranty coverage and looking for high-quality aftermarket parts can maximize cost control.