The ignition coil turns the battery’s low voltage into a high voltage, which ignites the engine’s air and fuel mixture. This only occurs with diesel engines with spark plug ignition or small gasoline engines (such as agricultural water pumps, tractor engines). If the ignition coil fails, the equipment may experience symptoms such as power loss, sparks, or. Read on to learn how to test the ignition coil. Includes the tools needed, common fault signs, and step-by-step testing methods.

What’s an Ignition Coil?

On a gas engine or a spark-ignited diesel engine, the ignition coil is a small electrical transformer. Its only job is to take the low-voltage power from your machine’s battery (usually 12 or 24 volts) and turn it into a huge electrical jolt—often over 40,000 volts. This high-voltage charge is what makes a strong spark at the spark plug. These coils are tough to handle all the vibration, heat, and dirt that come with off-road machine work. But just like any other part, they can wear out and fail over time.

How Does an Ignition Coil Work?

In each ignition coil, two sets of copper wire around the iron core: one is the primary coil, and the other is the secondary coil. When you turn the key, low-voltage electricity flows through the primary coil first, generating a magnetic field. The engine needs to be ignited, and the engine control module (old machines rely on contact circuit breakers) will cut off the current. Once the magnetic field disappears, an ultra-high voltage is induced in the secondary coil, igniting the oil-gas mixture in the cylinder.

The power of the engine is generated by this controlled small explosion. If the ignition coil is broken, the spark plug will produce a very weak or even no fire at all. The machine will naturally have various problems, such as a power drop, jitter, or difficulty starting.

What Are the Symptoms of a Faulty Ignition Coil?

When the ignition coil is about to fail, the machine will give you an obvious hint.

- The engine shakes badly: A missing cylinder means that a cylinder is not firing properly. At this time, you will feel the engine shaking vigorously, especially when idling or working under pressure. The shaking is more obvious. If it were an excavator, the cab would keep wobbling around, especially upside down.

- The power has deteriorated: Farm implements that used to be easily pulled by tractors are now difficult to pull; the hydraulic action of excavators has become slow and sluggish. This is most likely caused by one or more cylinders not being able to output power properly because the ignition coil is broken.

- Not good to start: When the spark weakens, it becomes difficult for the engine to ignite, which is more obvious when it is cold and wet. You might have to hold your keys in place for half a day before the engine barely starts.

- Higher fuel consumption: If the cylinder is missing, the unburned oil will be discharged directly from the exhaust pipe. The engine has to work harder to output the original power, and the fuel consumption is naturally much higher than usual.

- Exhaust pipe backfires or emits black smoke: Those unburned oils sometimes ignite a second time in the scalding exhaust manifold with a “bang” sound, which is called tempering. Black smoke also comes out of the exhaust pipe, which is a sign that the combustion is insufficient and the mixture is too thick.

- The engine suddenly shut down: In serious cases, a faulty ignition coil can cause the engine to stall suddenly, especially when the engine temperature is high or when it is suddenly stressed.

- Instrument panel fault light on: Many heavy equipment now have engine fault detection systems that can detect cylinder shortages. Once detected, the “Engine Malfunction Light” or other warning light on the

- The instrument cluster will illuminate: If your home machine has these conditions, it’s time to test it. After discovering the problem, the next step is to investigate and solve it.

How to Test an Ignition Coil?

With basic hand tools ready, you can test which coil caused the engine failure. Like a basic set of socket wrenches, screwdrivers, and possibly a multimeter for a more detailed diagnosis. NOTE: Use extreme caution when the engine is running. Hands, tools, and clothing are better away from belts, pulleys, and cooling fans. Ignition systems generate extremely high voltages that can cause electric shock.

Power Balance Test

Start the engine and let it idle steadily. Then unplug the ignition coil one at a time and pay attention to the engine changes.

- The engine shakes more after being unplugged: This means that the ignition coil and cylinder are normal. Plug it back in and continue to test the next one.

- The engine didn’t change after unplugging it: This means the ignition coil wasn’t working in the first place, and that’s where the problem lies.

Interchange Test (for Confirmation)

Shut down the engine. Remove the suspected bad ignition coil and a normal ignition coil next to it, swap the positions and install them. Restart the engine:

- The misfire followed the coil → The ignition coil failed.

- The problem is still with the original cylinder → it could be a spark plug, fuel nozzle or wiring issue.

Spark Visualization Test

Turn off the engine and remove the ignition coil and spark plug, but do not unplug them. Use insulating pliers to push the metal part of the spark plug against the bare metal of the engine (ground) and have someone help start it for a few seconds.

- The spark was thick, bright, bluish-white: normal.

- Very weak, orangeish spark, or no spark: The ignition coil voltage is insufficient and needs to a new one.

The Multimeter Resistance Test

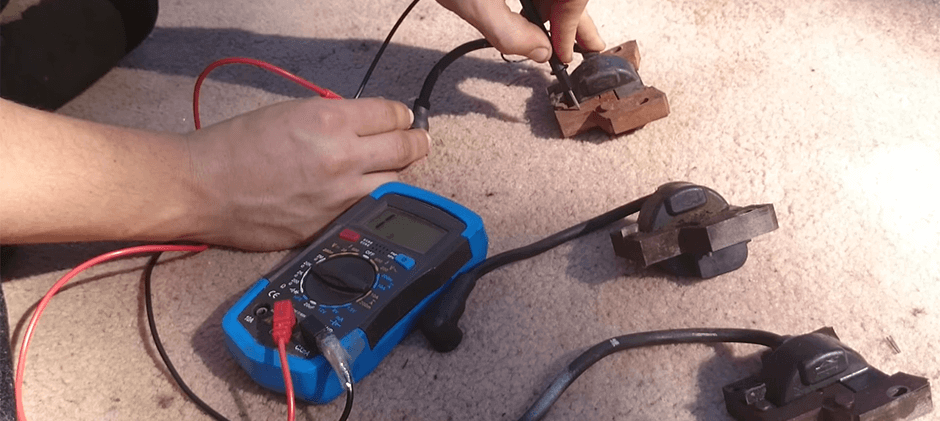

If you want a more accurate and reliable diagnosis, just use a digital multimeter. This method can check whether the winding inside the coil is bad. Remember first, be sure to turn off the engine and remove the coil from the engine before testing.

- Measuring the primary winding: Set the multimeter to ohmic (Ω) and select the smallest range, such as 200 Ω. Place the two watch pens on the positive (+) and negative (-) poles of the coil respectively. Normally, the reading will be very low, generally between 0.5 and 2.0 ohms.

- Measuring secondary winding: Then switch the multimeter to a larger ohmic range, such as 20k Ω. One stylus is also placed on the positive electrode (+), and the other stylus is inserted into the sleeve of the coil to touch the position where it contacts the top end of the spark plug. Normal readings this time will be much higher, usually between 6000 and 15000 ohms.

- What to think of the readings: Regardless of which item is measured, as long as infinity appears (the screen generally displays “OL” or “1”), the winding is broken; if the reading shows 0 ohms, the winding is short-circuited. Both of these situations mean that the coil is bad and cannot to used. In addition, please note that the resistance standards of coils in different models of equipment are different. It is best to check the accurate values in the machine’s maintenance manual.

Summing up

If the resistance reading is off or the spark test looks wonky, the ignition coil definitely needs replacing. If everything checks out fine, the problem is most likely not with the coil. There’s no set replacement schedule for ignition coils. A good-quality one can last a long time—even thousands of hours. But coils do wear out over time. This happens faster if spark plugs are poorly maintained or in bad shape. Always use high-quality replacement parts to ensure reliability and long service life.