Every operator should be familiar with the engine cooling system of their equipment. However, in the whole system, there is one component which is often overlooked, that is the radiator cap. Despite its small size, its function is extraordinary. If you are curious where its magical properties, then this article is very suitable for your reading. We will carefully talk about the working principle and basic function of the radiator cap, and teach you how to determine whether the radiator cap is damaged. Through this article, you will no longer have any doubt about the radiator cap.

How Does a Radiator Cap Work?

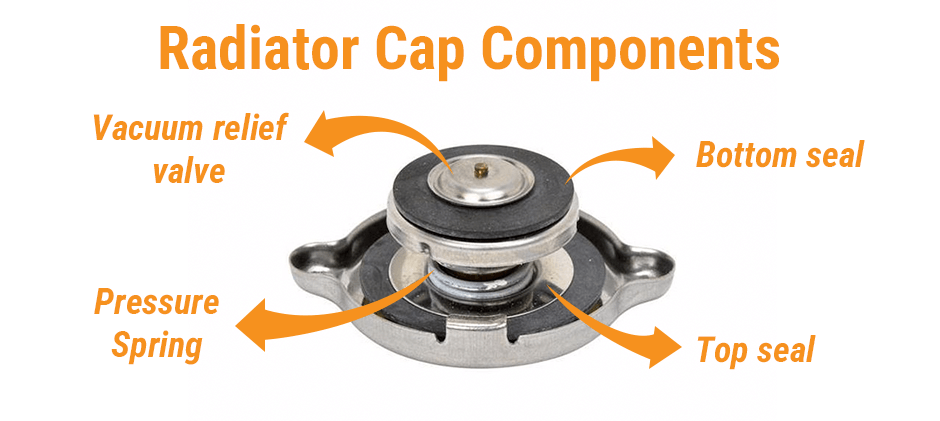

The radiator cap is a precision, spring-loaded, two-way valve that precisely manages pressure throughout the machine’s cooling system. Its operation can be divided into two distinct phases: the pressure cycle and the vacuum cycle.

-

The Pressure Cycle (When the Engine is Hot)

When the engine of the machine is operating under the load, it will produce heat. The coolant, which is the mixture of the antifreeze and the water, is circulating inside the engine cylinder body, and it is absorbing this heat. Along with the coolant becoming warm, it will expand. In the sealed system, this kind of expansion will be causing the pressure to increase significantly.

The radiator cap is designed with a large and calibrated pressure spring, which is used for resisting the pressure until a certain value, and this value is printed on the top of the cap (for example, 13 PSI, 16 PSI). As long as the system pressure is lower than this rated value, the cap will be keeping sealed, thus allowing the pressure to accumulate. Once the pressure is exceeding the rated value of the cap, it will be pushing back the spring and opening the valve. This is making the expanded hot coolant safely flow through the hose into the coolant overflow tank (also called the expansion reservoir). This operation is effectively releasing the over-large pressure, preventing it from reaching the level that may cause the hose to burst or the radiator to be damaged.

-

The Vacuum Cycle (When the Engine Cools Down)

After the engine is closed, the cooling process begins. The cooling liquid is no longer absorbing the heat, and it is starting to cool down and to shrink. This kind of shrinking of the liquid will form a vacuum inside the cooling system. If not to control it, the external atmosphere pressure maybe will be strong enough to crush down the radiator hose.

At this time, the second, smaller valve of the coolant cap—the vacuum valve—then plays its function. This valve is designed for opening inward when it detects a vacuum. When it is opening, it will form one channel, letting the coolant, which before was sent to the overflow tank, be siphoned back into the radiator. This clever mechanism ensures that the radiator is always full of liquid and prevents air from entering the system. Air pockets are very dangerous because they will cause corrosion, and also form the isolated “hot spots” inside the engine which cannot be cooled normally.

What is the Function of the Radiator Cap?

Through this delicate mechanical process, the radiator cap performs four vital functions that are essential to the health and performance of your heavy-duty engine.

1. Pressure Regulation

This is the radiator cap’s primary and most widely known function. It acts as a gatekeeper, maintaining the pressure within the cooling system at the optimal level specified by the engine manufacturer. This not only prevents leaks but is fundamental to the overall efficiency of the system.

2. Boiling Point Elevation

This is the key advantage of the pressure regulation. The physical law is showing that, along with the increase in the liquid pressure, its boiling point will also rise. This principle is the foundation of the modern cooling system. By keeping the system pressure, the coolant cap can significantly increase the boiling point of the coolant.

- A standard 50/50 coolant mix boils at about 223°F (106°C) at sea level.

- The cap adds pressure measured in PSI. Each PSI raises the boiling point about 3°F (1.6°C).

- Therefore, a 16-PSI cap can increase the coolant’s boiling point to over 270°F (132°C).

Off-road engines under continuous heavy load generate extreme heat. This extra temperature margin is vitally important.

3. Vacuum Prevention and Coolant Recirculation

As the engine cools, the cap’s vacuum valve pulls coolant back from the overflow tank. This double function prevents the hose from collapsing under vacuum. It also keeps the radiator full and eliminates air pockets.

4. Sealing the System

The most basic function of the cap is to provide a firm seal for the cooling system. This can prevent the coolant from losing due to evaporation or splashing, and, crucially, it can stop the entry of contaminants such as dust and debris into the system.

Where is the Radiator Cap?

Locating the radiator cap on your equipment is usually a simple process, but its location will vary according to the design of the cooling system. You usually can find it in one of the following two locations:

- Directly on the Radiator: In many traditional cooling systems, the metal high-pressure radiator cap is located on the top tank of the radiator itself, usually positioned on one side for the convenience of operation.

- On the Coolant Reservoir (Degassing Bottle): Many modern machines are equipped with full-pressure cooling systems, in which the overflow reservoir is also under pressure. In this configuration, the high-pressure cap is situated on this plastic reservoir, usually called the “degassing bottle.” The cap itself may be completely identical to a traditional radiator cap, or it may be specially designed for the coolant reservoir.

It is critical to know which type of system you have and to understand the difference between a radiator cap and a coolant cap. A true pressure cap will always have a PSI rating stamped on it, while a cap for a non-pressurized overflow tank is a simple, unrated plastic cap.

How to tell if a Radiator Cap is Bad?

Diagnosing a bad radiator cap is a quick and easy inspection that can save you from major headaches down the road.

CRITICAL SAFETY WARNING: Never attempt to remove the radiator cap when the engine is hot or warm. The system is bearing tremendous pressure, and opening the cap will cause scalding steam and coolant to spout out, thereby leading to serious burns. Before conducting any inspection, you must ensure that the engine has completely cooled

| Feature to Inspect | Good Radiator Cap | Bad Radiator Cap |

|---|---|---|

| Main Seal | The large rubber seal at the bottom is soft, pliable, and perfectly intact. | The seal is visibly cracked, hard, brittle, or has pieces missing. |

| Vacuum Valve Seal | The smaller seal in the center is also soft and intact. | The seal is deformed, gummy, or stuck to the cap body. |

| Pressure Spring | The large spring feels firm, strong, and springs back instantly when pressed. | The spring feels weak, soft, or gets stuck in a compressed position. |

| Metal Components | The metal surfaces are clean and free of major buildup. | There are clear signs of rust, corrosion, or a thick buildup of gunk. |

Besides the physical inspection, your machine itself can also usually provide clear evidence of the problem. If you continuously encounter cooling problems, it is best to understand the common symptoms of radiator cap failure, so as to help confirm your diagnosis.

Can a Bad Radiator Cap Cause Overheating?

Yes, without a doubt. A damaged radiator cap often causes engine overheating. It is one of the most common and overlooked reasons.

There exists a direct connection between the two. If the radiator cap’s main seal wears out, it cannot maintain pressure. The cooling system then becomes unpressurized. This means the boiling point of the coolant will revert to its normal, unpressurized temperature.

When your machine performs high-demand tasks such as digging compacted soil or climbing steep slopes, the engine temperature easily exceeds this lower boiling point. The coolant begins to boil inside the engine block, forming a large amount of vapor. Compared with the liquid, the thermal conductivity of the vapor is extremely poor. These vapors prevent the liquid coolant from contacting the high-temperature metal surfaces, causing the engine temperature to rise rapidly and creating danger. This may result in the warping of the cylinder head, burning of the cylinder head gasket, and other critical radiator components damage.

How Much is a Radiator Cap?

Considering the catastrophic damage a faulty cap can cause, the cost of a replacement is remarkably low. For most models of heavy equipment, a new, high-quality [radiator cap] will typically cost between $15 and $50. The price varies based on the brand of the machine and the specific pressure rating required.

Our radiator caps are reasonably priced and come with complete after-sales service. Their quality is comparable to the originals, meeting your price and quality needs. A radiator cap costs very little. An engine overhaul can cost tens of thousands. This makes the cap highly cost-effective preventive maintenance. It is a simple part that any operator can replace in seconds (on a cool engine), requiring no special tools or labor costs.

In Summary

The radiator cap is the main regulator of the cooling system, and it, as a precise valve, can protect your engine from the damage of its own harmful heat. By understanding how it is working, learning to identify its fault signs, and preventing the damage of the radiator cap, one can avoid it becoming the cause of high repair cost. When replacement is needed, a trustworthy supplier like FridayParts provides a large amount of affordable and high-quality aftermarket parts, ensuring the perfect operation of your machine’s cooling system.