Excessive engine temperature is one of the most obvious symptoms of a damaged radiator cap. The simplest and most direct way to immediately solve the problem of overheating in the engine might be to replace the radiator cap of your equipment. However, does a damaged radiator cap also cause other serious problems? How can one determine that the radiator cap is the actual cause of the problem? This guide will provide you with assistance.

We will explore the critical functions of a radiator cap in a heavy-duty cooling system. Showing you exactly what to look for in a failing cap. We also detail the seven key bad radiator cap symptoms that signal it’s time for a replacement.

Key Takeaway

- Engine Overheating – Cap can’t hold pressure, coolant boils early, engine temp spikes.

- Visible Coolant Leaks – Worn seal lets coolant escape around filler neck or onto ground.

- Overflow Reservoir Issues – Reservoir constantly overflowing or staying full while the radiator runs low.

- Collapsed Radiator Hoses – Vacuum valve stuck, hoses crushed flat as engine cools.

- Burst Hoses or Leaking Gaskets – Pressure not released, excess force damages the weakest parts.

- Air in Cooling System – A faulty seal draws in air, creating hot spots and poor cabin heating.

- Steam from Engine Bay – Pressurized coolant escapes violently, a clear sign of failure.

What is the Function of the Radiator Cap?

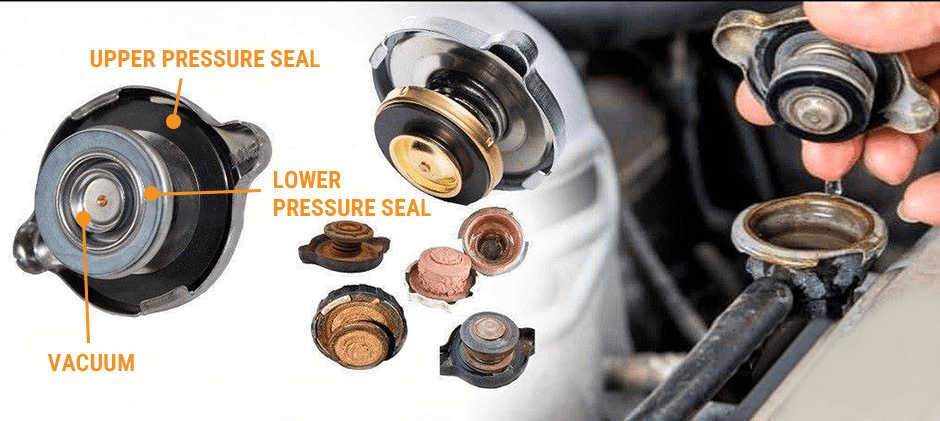

Do not be beguiled by its plain exterior; the radiator cap is a precisely designed bidirectional valve, playing a crucial role in the health of the machine. Its function is far more complex than merely sealing the radiator opening.

- Pressurizing the System: The cap’s primary function is to maintain a specific level of pressure within the cooling system (typically 13 to 16 PSI for heavy equipment). Pressurizing the coolant raises its boiling point. For example, a 15 PSI cap can raise the boiling point of a 50/50 coolant mix from around 223°F (106°C) to over 260°F (127°C). This extra margin is critical for off-road machinery engines that generate immense heat under constant load.

- Sealing the System: It creates an airtight seal that prevents coolant from evaporating and stops air from being drawn into the system, which could cause corrosion and dangerous hot spots in the engine.

- Pressure Relief: The cap contains a spring-loaded pressure valve. If the pressure inside the cooling system exceeds the cap’s rating, this valve opens and allows hot, expanded coolant to flow safely into the overflow reservoir. This prevents excessive pressure from bursting hoses or damaging radiator seams.

- Vacuum Relief: As the engine cools down, the coolant contracts, creating a vacuum inside the system. The cap has a second, smaller vacuum valve that opens to allow coolant from the overflow reservoir to be drawn back into the radiator. This keeps the system completely full and free of air pockets.

Think of the radiator cap as your cooling system’s gatekeeper. It controls pressure, prevents boiling, manages expansion, and keeps everything sealed tight. When it fails, the whole system suffers. At FridayParts, we see operators chasing complex cooling problems only to discover a worn radiator cap was the culprit all along.

What Does a Bad Radiator Cap Look Like?

Knowing the appearance difference between a faulty radiator cap and a good radiator cap is the initial step of visual inspection.

- A good radiator cap: clean and tidy, with top metal luster. When pressing the large pressure spring beneath, it feels solid and durable. Most importantly, the rubber sealing ring (the large seal at the bottom and the smaller vacuum seal at the top) is soft, elastic, and intact.

- A damaged radiator cap: you will observe obvious wear marks. The metal components may rust or corrode. The large spring maybe feel weak or stuck in compress place. The main feature is the rubber sealing ring; need to check whether it has cracks, become brittle, become hard, or show obvious damage. Also, you maybe will notice that around the sealing ring have dry coolant remaining or dirt, which indicates the sealing is not good.

7 Signs of a Bad Radiator Cap

If you suspect an issue, watch for these seven key warning signs. These symptoms of bad radiator cap failure range from subtle to severe and almost always point to a cap that can no longer do its job.

1. Engine Overheating

This is the most serious and ultimate outcome of a failing radiator cap. If the cap can’t hold pressure, the coolant’s boiling point drops significantly. Under a heavy workload, the coolant can begin to boil, creating vapor pockets that don’t transfer heat effectively. This leads to a rapid rise in engine temperature, forcing a shutdown and risking severe engine damage.

2. Visible Coolant Leaks

A worn-out main seal on the cap will fail to seal the radiator neck properly. When the system pressurizes, hot coolant will be forced out around the cap. You’ll often see signs of this as:

- White, crusty streaks or stains around the radiator filler neck.

- Puddles of brightly colored coolant (green, orange, or pink) on the ground directly below the radiator.

- A constantly low coolant level, even without any other visible leaks.

3. Overflow Reservoir Problems

The coolant reservoir (or expansion tank) is a direct indicator of the radiator cap’s health.

- Coolant reservoir overflow: If the radiator cap’s pressure spring is too weak, it will release pressure prematurely, causing coolant to continually flow into the reservoir and overflow.

- Reservoir is empty: If the radiator cap’s vacuum valve sticks closed, the cooling engine cannot draw the coolant back from the reservoir when cooling. The radiator will become low on fluid while the reservoir remains full.

4. Collapsed Radiator Hoses

This is a classic sign of a faulty vacuum valve on the cap. When your machine’s engine cools down, the liquid coolant contracts, creating a powerful vacuum. A working cap allows coolant from the reservoir to be sucked back in to fill this void. If the vacuum valve is stuck, nothing can get back in, and the atmospheric pressure outside the hose is strong enough to literally crush it flat. You’ll notice the large upper radiator hose looks squashed or feels spongy.

5. Burst Hoses or Leaking Gaskets

This is the opposite problem: the pressure valve is stuck closed. It fails to release excess pressure into the overflow tank. As the engine works hard, pressure builds to dangerous levels, far exceeding the system’s design limits. This immense pressure seeks out the weakest point, which could be an old hose, a hose clamp, or even a gasket. This is often where the bad radiator cap or head gasket confusion comes in. A sudden coolant leak from the engine block could be a catastrophic head gasket failure, but it could also be caused by extreme over-pressurization from a cheap, faulty radiator cap. Always check the cap first.

6. Air in the Cooling System

If the cap’s seals are compromised, it can allow air to be sucked into the system as it cools down. These air pockets can get trapped in the radiator, engine block, and heater core. This leads to inefficient cooling, creating hot spots within the engine. A common symptom of this on machines with enclosed cabs is a heater that blows lukewarm or cold air, as an air pocket is trapped in the heater core.

7. Steam from the Engine Bay

This is a dramatic symptom that demands immediate attention. If you see steam billowing from under the hood, it’s typically because pressurized, boiling coolant is escaping from a failed cap or a burst hose. Pull over and shut down the engine immediately to prevent catastrophic damage.

| Symptom | What It Indicates | Severity |

|---|---|---|

| Coolant loss (no visible leak) | Pressure seal failure | Medium |

| Engine overheating | Pressure not maintained | High |

| Collapsed hoses | Stuck vacuum valve | Medium |

| Swollen/hard hoses | Pressure relief failure | High |

| Overflowing reservoir | Venting too easily | Medium |

| Air in the system repeatedly | Seal leaking | Medium |

| Coolant smell/steam | Escaping vapor | Medium |

Checking the Radiator Cap is Necessary

Regularly checking your radiator cap is one of the cheapest and easiest forms of preventative maintenance you can perform. Ignoring it can have severe consequences.

A five-dollar radiator cap can protect a fifty-thousand-dollar engine. There is no better return on investment in heavy equipment maintenance than ensuring your cooling system is properly sealed and pressurized.

A faulty cap directly leads to engine overheating, which can cause warped cylinder heads, blown head gaskets, and complete engine seizure. The cost of these repairs can run into the tens of thousands of dollars, all for a part that costs less than a good lunch. A quick inspection during your routine fluid checks is all it takes.

Safety First: Must not try to open radiator cap when engine is hot, even just warm. Because the system is in a high-pressure condition, if open cap then boiling coolant and steam will spray out, causing serious burns. Must wait until the engine becomes completely cool, then can open.

When Do You Need to Replace a Radiator Cap?

You should make a plan for replacement under two conditions:

- At the first time when appears symptoms of fault: If you find any one among the above seven symptoms, or by eye seeing discover a crack, corrosion, or a sealing part already damaged, then you must immediately change the radiator cap.

- As preventive maintenance: Because of long-time heat cycles and pressure, the rubber sealing and spring will little by little become wear. The wise way is to take the radiator cap as one part of routine cooling system maintenance (for example, every two years or every 2000 working hours) together with coolant and hose to do a change.

Other Cooling System Problems That Mimic a Bad Radiator Cap

Sometimes symptoms that seem like a bad cap actually stem from other cooling system issues. Let’s look at common culprits.

- Leaking Head Gasket: A blown head gasket can cause coolant loss, overheating, and air in the system – exactly like a bad cap. But head gasket failure is far more serious and expensive. Key differences: head gasket leaks often cause white exhaust smoke, milky oil, or bubbles in the radiator. A pressure test showing rapid pressure loss with no external leaks suggests head gasket problems.

- Thermostat Failure: A stuck-closed thermostat blocks coolant circulation, causing overheating. Unlike a bad cap, this overheating is consistent and severe, often happening quickly. The lower radiator hose stays cool while the upper hose gets extremely hot, indicating no coolant flow through the radiator.

- Water Pump Failure: A failing water pump reduces coolant circulation, causing overheating and possibly coolant leaks from the pump shaft seal. Listen for grinding noises from the pump bearing or check for wobble in the pump pulley. These symptoms don’t occur with a bad radiator cap.

- Clogged Radiator: Internal radiator blockage from rust, scale, or debris restricts coolant flow. The engine overheats while the radiator stays relatively cool. Thermal imaging or temp guns reveal hot and cold spots across the radiator face. A bad cap causes overall cooling inefficiency, not localized blockage.

- Air Locks: Large air pockets trapped in the cooling system create circulation problems similar to a bad cap. However, proper bleeding procedures should remove air locks, while cap problems persist after bleeding. If air repeatedly returns, then suspect the cap’s seal.

The key is proper diagnosis. Don’t assume the cap is bad just because you have cooling problems. Test the cap first, then systematically check other components if needed. This approach saves money by replacing only what’s actually faulty.

Choosing the Right Radiator Cap Replacement

Radiator caps are not a one-size-fits-all component. Using the wrong one can be just as damaging as using a faulty one. The most critical factor is the pressure rating, which is always stamped on top of the cap (e.g., “13 PSI,” “16 PSI”).

- Always use a cap with the same PSI rating as specified by your machine’s manufacturer.

- Using a cap with a lower PSI rating will cause the coolant to boil at a lower temperature, leading to overheating.

- Using a cap with a higher PSI rating will put excessive pressure on your hoses, radiator, and gaskets, risking a blowout.

It’s also important to differentiate between a coolant cap (often a simple, non-pressurized screw-on cap for the overflow reservoir) and a true radiator cap. To fully grasp the distinction between these two caps, it’s helpful to recognize that only the one on the radiator or pressurized degas bottle is designed to hold pressure.

In Finally

The radiator cap is a small but mighty defender of your heavy equipment’s engine. To ensure the engine operates with high efficiency, make sure the radiator cap can realize precise pressure control. And master the art of recognizing signs that the radiator cap requires replacement. If necessary, perform repair and replacement to avoid more costly losses. When choosing a new radiator cap, you can consider suppliers like FridayParts. We offer a wide range of high-quality and reasonably priced aftermarket parts to meet all your needs during equipment maintenance.