Your EGR cooler helps reduce emissions and keep your engine running efficiently. When it starts to fail, your equipment can suffer serious damage if you don’t catch the warning signs early. But no worry, FridayParts’ expert is here for you. Let’s walk through everything you need to know about spotting a failing one before it becomes a major headache.

What Does an EGR Cooler Do?

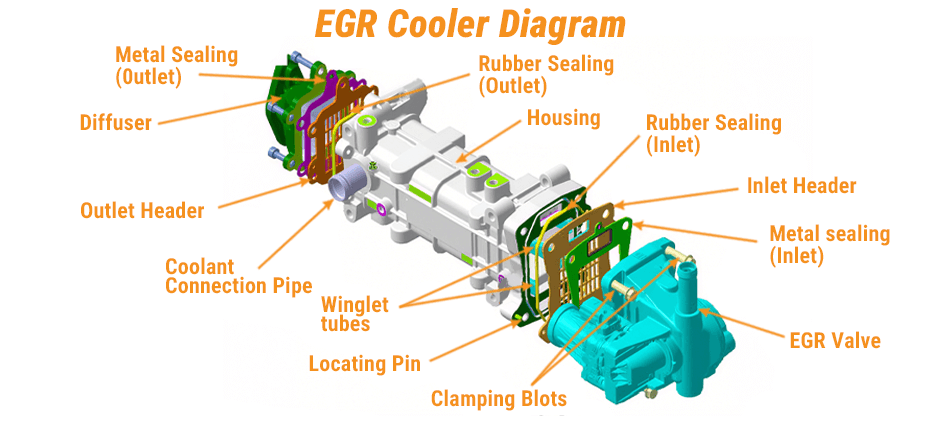

Before we jump into failure symptoms, let’s understand what this component actually does. The EGR (Exhaust Gas Recirculation) cooler is part of your emissions control system. It takes hot exhaust gases and cools them down before sending them back into the engine’s intake manifold.

Why cool the gases? Cooler exhaust gases lower the combustion temperature in your engine cylinders. Lower combustion temperatures mean less nitrogen oxide (NOx) emissions, which is better for the environment and helps you meet emissions regulations. The EGR cooler uses engine coolant flowing through tubes or passages to extract heat from the exhaust gases.

This component works incredibly hard in demanding conditions. It handles extremely hot exhaust gases, often reaching temperatures over 1000°F, while simultaneously being exposed to engine coolant. This constant thermal cycling and exposure to corrosive exhaust gases put enormous stress on the EGR cooler over time.

At FridayParts, we see plenty of heavy equipment operators dealing with these issues, especially in diesel engines found in excavators, loaders, and tractors. Recognizing the early warning signs can save you thousands in repair costs.

Related content: EGR Cooler Maintenance Guide: When? How?

Common Signs Your EGR Cooler Is Failing

- White Smoke From the Exhaust: One of the most obvious symptoms of a failing EGR cooler is white smoke billowing from your exhaust pipe. This happens when coolant leaks into the exhaust stream through cracks or holes in it. The coolant burns off as steam, creating thick white smoke that’s especially noticeable during startup or under load. If you see white smoke that doesn’t quickly disappear after a cold start, your EGR cooler might be the culprit.

- Coolant Loss Without Visible Leaks: Are you constantly topping off your coolant reservoir, but can’t find any puddles under your equipment? An internal leak could be the reason. When the cooler develops cracks, coolant seeps into the exhaust system, where it evaporates, leaving no trace on the ground. Check your coolant level regularly – if it’s dropping faster than normal with no external leaks, suspect the EGR cooler.

- Engine Overheating: A clogged or damaged EGR cooler can restrict coolant flow through your engine’s cooling system. When coolant can’t circulate properly, your engine temperature climbs. You might notice your temperature gauge creeping higher than usual, especially during heavy work or hot weather. Don’t ignore this warning – overheating can cause catastrophic engine damage.

- Check Engine Light and Fault Codes: Modern equipment has sensors that monitor the EGR system’s performance. When the EGR cooler fails or becomes clogged, it triggers fault codes and illuminates your check engine light. Common codes related to its failure include those indicating insufficient EGR flow, EGR temperature sensor issues, or coolant temperature problems. Getting these codes read quickly helps pinpoint the issue before it worsens.

- Poor Engine Performance: A failing EGR cooler affects how your engine runs. You might experience rough idling, hesitation during acceleration, or reduced power output. The engine may struggle under load or feel sluggish compared to normal operation. These performance issues occur because the EGR system can’t properly regulate exhaust gas recirculation, throwing off the air-fuel mixture.

- Coolant in the Exhaust System: If you can safely inspect your exhaust system, look for signs of coolant contamination. Milky residue around exhaust pipes, moisture that smells sweet like coolant, or rust-colored deposits can all indicate that coolant is escaping through the EGR cooler into the exhaust.

| Symptom | What It Means | Urgency Level | Potential Damage |

|---|---|---|---|

| White smoke from the exhaust | Coolant burning in the exhaust | High | Engine damage, catalytic converter failure |

| Coolant loss (no visible leak) | Internal EGR cooler leak | High | Overheating, cylinder damage |

| Engine overheating | Restricted coolant flow | Critical | Head gasket failure, warped heads |

| Check engine light | EGR system malfunction | Medium | Failed emissions test, reduced efficiency |

| Poor performance | Improper EGR function | Medium | Increased emissions, fuel waste |

Related: How Much Does the EGR Cooler Replacement Cost

What Causes Its Failure?

Several factors contribute to EGR cooler deterioration over time. Just put these in mind so that next time when it’s down, check this list first to help you fix your EGR Cooler.

- Thermal Stress and Fatigue: It constantly expands and contracts as it heats up and cools down. This thermal cycling creates stress on the metal components, eventually leading to cracks. The extreme temperature differential between hot exhaust gases (over 1000°F) and cool engine coolant (around 200°F) accelerates this process.

- Corrosion and Contamination: Exhaust gases contain corrosive elements like sulfur, carbon deposits, and moisture. These contaminants attack the EGR cooler’s internal surfaces over time. On the coolant side, poor coolant quality, contaminated coolant, or infrequent coolant changes can cause internal corrosion and scale buildup. This deterioration weakens the cooler walls until they crack or develop pinhole leaks.

- Carbon Buildup and Clogging: Soot and carbon deposits from exhaust gases accumulate inside the EGR cooler passages. This buildup restricts exhaust flow and reduces cooling efficiency. Eventually, the blockage can cause backpressure problems and prevent the EGR system from functioning properly. Clogged coolers also trap heat, accelerating thermal damage.

- Manufacturing Defects: Some EGR coolers have design flaws or manufacturing defects that make them prone to premature failure. Certain engine models and years have known EGR cooler problems. If you’re experiencing repeated failures, it might be worth investigating whether there’s a recall or updated part available.

- Operating Conditions: Heavy-duty applications, frequent idling, and stop-and-go operation all stress the EGR system more than highway driving. Equipment operating in dusty or dirty environments may experience faster deterioration. Similarly, using low-quality diesel fuel or biodiesel blends can increase soot production and accelerate clogging.

How to Test and Diagnose EGR Cooler Problems

If you suspect EGR cooler failure, several diagnostic steps can confirm your suspicions before you spend money on replacement parts.

- Visual Inspection: Start with a thorough visual check. Look for coolant stains, corrosion, or cracks around the EGR cooler and connecting pipes. Inspect coolant hoses for swelling or softness, which indicates contamination from exhaust gases. Check the coolant reservoir for oil contamination or unusual discoloration that might signal a failing EGR cooler.

- Pressure Testing: A cooling system pressure test can reveal internal EGR cooler leaks. With the system pressurized, coolant will seep through cracks in the EGR cooler into the exhaust passages. You might see pressure dropping on the gauge or find coolant in places it shouldn’t be. This test is one of the most reliable ways to confirm an internal leak.

- Exhaust Gas Analysis: Checking for hydrocarbons in the coolant can indicate exhaust gases contaminating the cooling system through a failed EGR cooler. Special test equipment can detect these gases in the coolant reservoir. Similarly, testing exhaust emissions can show whether the EGR system is functioning properly.

- Scan Tool Diagnostics: Use a diagnostic scan tool to read fault codes and monitor EGR system data. Look at EGR temperature readings, flow rates, and related sensor values. Compare actual readings to expected values for your specific engine. Live data monitoring while the engine runs can reveal intermittent problems that don’t always trigger codes.

What to Do When Your EGR Cooler Fails

Once you’ve confirmed its failure, you need to act quickly to prevent further engine damage. Here’s what we recommend.

- Stop Operating the Equipment: Continued operation with a failed EGR cooler can cause severe engine damage. Coolant entering the combustion chambers can wash away cylinder lubrication, score cylinder walls, and damage piston rings. It can also contaminate engine oil and damage your catalytic converter or diesel particulate filter. The cost of these repairs far exceeds the cost of replacing just the EGR cooler.

- Get Professional Diagnosis: While we’ve outlined symptoms and tests, a qualified technician should verify the diagnosis. They can rule out other issues that mimic EGR cooler failure and ensure you’re replacing the right component. Professional diagnosis also catches related damage that needs attention.

- Replace, Don’t Repair: They are generally not repairable. Once they develop cracks or internal leaks, replacement is the only option. Some operations attempt to clean clogged EGR coolers, which can extend their life if caught early, but this is temporary at best.

- Address Related Issues: When replacing it, flush the entire cooling system to remove any contamination. Replace the coolant with fresh, high-quality coolant mixed to the proper concentration. Inspect EGR valves, sensors, and connecting pipes for damage or excessive carbon buildup. Clean or replace components as needed to ensure the new EGR cooler performs properly.

- Consider Preventive Measures: After replacement, implement a maintenance schedule to maximize the new cooler’s lifespan. Use quality diesel fuel, maintain proper coolant service intervals, and avoid excessive idling when possible. Some operators install EGR delete kits in off-road equipment, though this may violate emissions regulations depending on your application.

At FridayParts, we stock replacement EGR coolers and cooling system components for a wide range of heavy equipment. Quality aftermarket parts can provide reliable performance at a fraction of dealer prices.

FAQs About EGR Cooler Failure

How long does an EGR cooler typically last?

They typically last between 80,000 to 150,000 miles under normal operating conditions, though this varies widely based on application, maintenance, and operating environment. Heavy-duty diesel equipment may see shorter lifespans due to more demanding service. Regular maintenance and using quality coolant can extend the EGR cooler’s life.

Can I drive with a bad EGR cooler?

No, you should not operate equipment with a failed one. Coolant leaking into the combustion chambers can cause severe engine damage, including scored cylinders, damaged piston rings, contaminated engine oil, and ruined catalytic converters. The repair costs for this collateral damage far exceed EGR cooler replacement costs.

What happens if I ignore the EGR cooler failure?

Ignoring its failure leads to progressive engine damage. Coolant contamination damages cylinder walls, piston rings, and bearings. Exhaust backpressure from a clogged cooler reduces performance and fuel economy. Eventually, you’ll face major engine repairs or complete engine replacement costing tens of thousands of dollars.

Can I clean a clogged EGR cooler instead of replacing it?

Cleaning a clogged one can work if caught early and if there’s no structural damage. Professional cleaning services use chemical solutions or specialized equipment to remove carbon deposits. However, if the cooler has cracks, leaks, or severe corrosion, cleaning won’t help. Replacement is the only solution for damaged coolers.

Your EGR cooler might be tucked away in your engine bay, but its health directly impacts your equipment’s performance and longevity. Watch for the warning signs we’ve discussed, and don’t delay diagnosis and repair when problems arise. Catching its failure early prevents expensive engine damage and keeps your operation running smoothly. For quality replacement parts and expert support, trust FridayParts to keep your equipment in top condition.