The off-road machinery is complicated, so when it breaks down, even an equipment professor may not know where it is going wrong. This guide will focus on the EGR cooler. What is it and what is it for? What happens if it goes wrong? And when you need to clean & replace it, how? Whatever you are wondering about, this guide will give you answers. Follow this guide and fix the tricky problems!

What Is an EGR Cooler and Why Is It Important?

The main job of the EGR system is to cut down on harmful pollutants (specifically Nitrous Oxides, or NOx) created by the intense heat inside your engine. It does this by routing a small amount of inert (already burned) exhaust gas back into the engine’s air intake. This recycled gas lowers the extreme combustion temperatures (which can exceed 1,300°C / 2,400°F) that create NOx.

The EGR cooler makes this process far more effective. A cooler gas is much better at reducing temperature than a hot gas. The cooler’s only job is to chill the exhaust before it’s recycled, drastically improving its ability to reduce emissions and helping your expensive machine meet strict environmental laws.

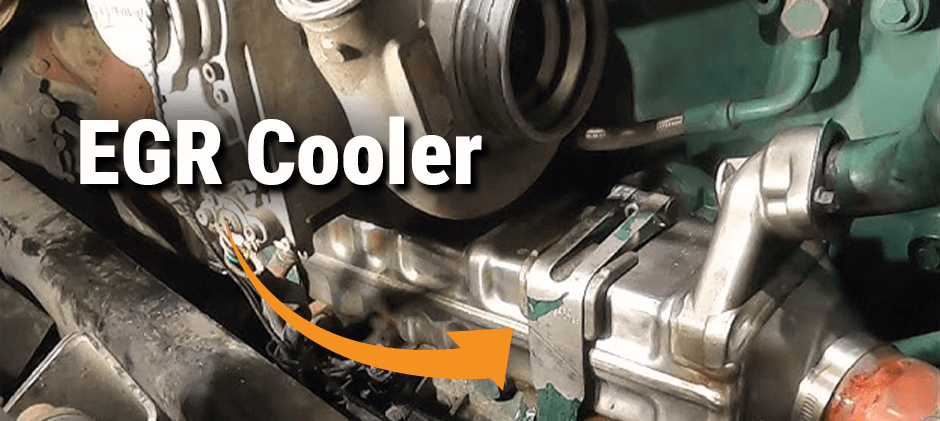

Location

You will find the EGR cooler mounted directly to the engine, connected by heavy-duty pipes to the exhaust manifold. It’s a metal box or cylinder with both exhaust tubing and engine coolant hoses attached to it.

Working Process

The cooler is a simple but tough water-to-air heat exchanger:

- Hot exhaust gas is piped from the exhaust manifold directly into the cooler.

- Inside, the gas flows through a series of reinforced, sealed tubes.

- At the same time, engine coolant flows in a separate passage around these hot tubes.

- Heat from the exhaust transfers through the tube walls and is absorbed by the coolant, which then carries the heat away to the machine’s main radiator.

- The now-cooler exhaust gas exits the unit and continues to the engine’s air intake.

Application

The EGR cooler is a critical emissions control device. Its entire purpose is to ensure your machine operates cleanly under tough conditions.

Emissions Compliance: This system is essential for making modern diesel engines meet environmental regulations for NOx, the pollutants that cause smog and acid rain.

Lowers Combustion Temperature: By introducing cooled, inert gas, it prevents the extreme temperature spikes that create NOx.

Reduces Harmful Pollutants: It directly lowers the formation of NOx gases in the combustion chamber.

Common Machinery:

- Construction Equipment: Excavators, wheel loaders, dozers, and articulated trucks.

- Agricultural Machinery: Tractors, combines, harvesters, and sprayers.

Why Clean & Replace Your EGR Cooler Is Important?

A faulty EGR cooler is a ticking time bomb. Because it connects your machine’s exhaust and cooling systems, an internal crack creates a direct pathway for disaster, turning a manageable repair into a five-figure engine replacement. For an equipment owner, this isn’t just maintenance—it’s preventing catastrophic downtime and financial loss. When a cooler fails, one of two things happens:

1. Coolant Enters the Exhaust

The cooling system’s pressure forces coolant into the hot exhaust stream, instantly creating the classic “white smoke” from the stack. More critically, this coolant is routed back into the engine’s intake. Since liquid doesn’t compress, this can cause hydrolock—a sudden, violent seizure that can bend connecting rods, crack a cylinder head, or destroy the entire engine.

2. Exhaust Enters the Coolant

Under heavy load, high-pressure exhaust gas can be forced into your cooling system. This creates air pockets, pushes coolant out of the overflow, and quickly causes the engine to overheat, risking warped heads and other major thermal damage.

Cleaning a clogged cooler is vital for preventative maintenance. Replacing a cracked cooler is non-negotiable engine insurance. Ignoring the warning signs is a gamble no business can afford to take.

When to Clean Your EGR Cooler

You should only clean your cooler if it is clogged with soot but has not failed internally. Cleaning is meant to restore flow, not to fix a crack.

4 Signs You Need to Clean:

- Check Engine Light: You have active fault codes for “low EGR flow” or “insufficient EGR flow.”

- Gradual Loss of Power: The machine feels sluggish under load. It struggles with grades or takes longer to complete cycles.

- Increased Fuel Consumption: You notice you’re burning more fuel than usual to do the same amount of work.

- The Key Sign: You are experiencing the symptoms above, but you are NOT losing coolant, and there is NO white smoke from the exhaust stack.

Step-by-Step Cleaning Guide

This is a dirty job that can take several hours. If you are not comfortable with it, have your mechanic perform the service.

- Remove the Cooler: Carefully disconnect the coolant lines and exhaust piping, and remove the EGR cooler from the engine. Be prepared for some coolant spillage.

- Seal One End: Use a rubber plug, cap, or heavy-duty tape to completely seal one of the exhaust ports on the cooler.

- Fill and Soak: Stand the cooler upright and fill the exhaust side with a dedicated EGR cleaner or a strong carbon-dissolving degreaser. Let it soak for several hours, or even overnight for heavy buildup. Warning: Avoid using highly flammable liquids like carburetor cleaner, as any remaining vapor could ignite upon engine start-up.

- Rinse Thoroughly: Drain the black, sludgy liquid. Aggressively flush the cooler out with hot water until the water runs clear.

- Dry Completely: Use compressed air to blow all water out of every passage. It must be completely dry inside before reinstallation.

- Reinstall with New Gaskets: Never reuse old gaskets. Install the clean cooler using a new set of gaskets to prevent leaks.

When to Replace Your EGR Cooler

You must replace your cooler if it has an internal leak. No amount of cleaning can fix a cracked cooler.

4 Signs You Need to Replace:

These are not suggestions; they are stop-work signs. Shut the machine down as soon as it is safe.

- White Smoke From the Exhaust: This is the #1 sign of a major internal leak. It’s not smoke; it’s steam from your engine coolant being boiled away.

- Unexplained Coolant Loss: The coolant level in your overflow bottle keeps dropping, but you can’t find a puddle on the ground. The engine is drinking it.

- Engine Overheating Under Load: The temperature gauge spikes when you’re working the machine hard. This indicates exhaust is likely pushing into your coolant.

- Slimy, Wet EGR Valve: This is a definitive physical sign. Remove the EGR valve. If it’s coated in a dry, black soot, it’s likely okay. If it’s covered in a wet, black, tar-like slime, that is the unmistakable residue of coolant mixing with exhaust soot.

Step-by-Step Replacing Guide

- Stop Operation Immediately: Prevent catastrophic engine damage.

- Confirm the Diagnosis: A mechanic can pressure-test the cooler off the machine to confirm an internal leak.

- Source a High-Quality Part: This is not the place to save money. A cheap replacement will fail again. Look for a heavy-duty aftermarket cooler built with durable stainless steel tubes and reinforced welds designed to handle the heat cycles of a working machine.

- Professional Installation: This is a job for a qualified heavy-duty mechanic. They will ensure it is installed correctly with new gaskets.

- Address the Root Cause: A smart mechanic will also check for other issues. A failing oil cooler can send sludge into the cooling system, restricting flow and overheating the EGR cooler. A weak water pump can do the same. Ensure the entire cooling system is healthy to protect your new investment.

Find Reliable EGR Cooler: Why Choose FridayParts?

Handling the maintenance methods is not enough; you also need a reliable replacement part for your machinery, because a cheap, poorly made EGR cooler is just a temporary fix that is doomed to fail again.

FridayParts specializes in offering OEM-quality parts at a competitive price. Here’s why they are a better choice for your equipment:

Superior Durability and Construction

- Heavy-Wall Stainless Steel Tubes: Provides maximum resistance to cracking caused by extreme heat cycles and engine vibration.

- Reinforced TIG Welds: Creates stronger, more reliable joints at critical stress points to withstand high-pressure conditions without failing.

Optimized for Longevity and Performance

- Advanced Internal Design: Features tube designs that resist soot and carbon buildup, maintaining proper exhaust flow.

- Prevents Hot Spots: By reducing clogging, our coolers prevent the localized overheating that is a primary cause of internal cracks and failure.

Guaranteed Fit and Wide Compatibility

- Direct-Fit Replacement: Engineered to exact OEM specifications for a hassle-free installation with no modifications needed.

- Extensive Fleet Coverage: We offer reliable solutions for a vast range of equipment, including major brands like Hitachi, John Deere, Kubota, Isuzu, Bobcat, and more.

Browse our full selection of heavy-duty EGR coolers at FridayParts.com now! Our one-year warranty and 90-day return period guarantee you enjoy a pleasant shopping experience.