As an experienced operator, you must have met this situation before: your coolant level is dangerously low, while there is only a bottle of water nearby. Can I put water in my coolant tank?

The short answer: Yes, but only in a genuine emergency, and it’s a temporary fix. The long answer explains why coolant matters and what to do in every situation to protect your engine and avoid costly downtime.

Why Water Can’t Replace Coolant

Many people think coolant (or antifreeze) is just colored water — it’s not.

Coolant is a special fluid designed to do three important jobs that plain water simply can’t: prevent boiling, freezing, and corrosion.

1. Boil-Over Protection

Water boils at 212°F (100°C).

Modern diesel engines often run at or near that temperature. If water boils, it turns into steam — and steam can’t cool your engine properly. That creates hot spots that can warp or crack engine parts.

Pro Tip: Even though a pressurized cooling system raises water’s boiling point slightly, a 50/50 coolant mix raises it much higher — up to 265°F (130°C) — giving your engine a safe buffer against overheating.

2. Freeze Protection

Water freezes at 32°F (0°C) and expands as it turns to ice.

That expansion can crack your engine block, split the radiator, or burst hoses.

A 50/50 coolant mixture protects your engine down to about -34°F (-37°C), keeping everything safe through the coldest weather.

3. Corrosion and Scale Protection

Your cooling system has many types of metal: aluminum, steel, copper, and brass.

Using plain water, especially tap water, introduces minerals and oxygen that cause rust and scale buildup.

Over time, that can block coolant flow and wear out parts like the water pump or radiator.

Coolant, on the other hand, contains protective additives that:

- Stop corrosion and rust,

- Prevent mineral buildup (scale), and

- Lubricate seals and moving parts.

That’s why the right coolant mix always lasts longer and protects better than plain water — in any climate.

How to Use Water Safely in an Emergency

If your machine is overheating and leaking coolant, using water temporarily is better than letting the engine seize — but you must do it safely.

Step-by-Step:

1. Shut Down Immediately

Don’t open the radiator cap while the engine is hot. Wait until it’s completely cool (at least 1 hour).

2. Choose the Best Water Available

- Best: Distilled water — no minerals or impurities.

- Good: Bottled or purified water.

- Last resort: Tap water — only if there’s no other option.

3. Add Water Slowly

Open the coolant reservoir cap and fill only to the “MAX” mark.

4. Drive Carefully to Safety

This is just to get your machine to a repair shop or back to base — not for ongoing use.

5. Flush and Refill ASAP

Once safe, repair any leaks, flush the system, and refill with the correct coolant mix. The water you added has diluted the protective chemicals — leaving your engine unprotected if left too long.

Coolant Maintenance for Heavy Equipment

Proper coolant care is essential for dozers, excavators, loaders, and other heavy machinery. Failures from overheating or corrosion can cause expensive downtime. Here’s what every operator should know:

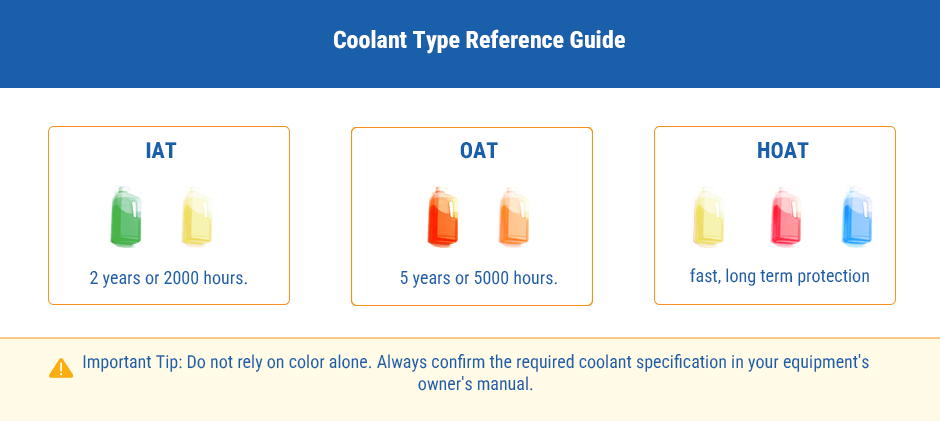

1. Know Your Coolant Type

Always check your owner’s manual for the right type:

| Coolant Type | Common Color | Description |

|---|---|---|

| IAT (Inorganic Acid Tech) | Green/Yellow | Standard coolant needs frequent changes (~2 years or 2,000 hours). |

| OAT (Organic Acid Tech) | Red/Orange | Extended-life type, often good for 5 years or 5,000 hours. |

| HOAT (Hybrid Organic Acid Tech) | Yellow/Pink/Blue | Blend of both — fast, long-term protection. |

Tip: Don’t rely on color alone — always confirm specs.

2. Inspect Daily

During your pre-start walk-around, check the coolant level in the expansion tank.

A slow drop may point to a small leak or a failing component.

3. Test Coolant Condition Regularly

Use:

- A refractometer to check freeze/boil protection.

- Test strips to measure pH and corrosion inhibitor strength.

This helps you catch issues before they cause damage.

4. Flush on Schedule

Even long-life coolant breaks down over time.

Follow your manufacturer’s flush and refill intervals — skipping them often leads to radiator or water pump failures down the road.

5. Never Mix Types

Mixing different coolant brands or formulas can cause chemical reactions that form thick gel-like deposits — clogging the entire cooling system.

The Bottom Line

You can use water in your coolant tank — but only as a short-term solution in an emergency.

Running water long-term leads to boiling, freezing, corrosion, and engine failure.

Your coolant is more than a liquid — it’s essential engine protection.

Keep Your Equipment Cool with FridayParts

At FridayParts, we know how critical cooling systems are to your uptime.

We offer radiators, water pumps, coolant hoses, temperature sensors, and high-quality engine overhaul kits — all designed for long-lasting performance, keeping your heavy equipment running strong, no matter how tough the job site gets.