An overheating engine or a heater that blows cold on a frosty morning is a frustrating sign for any tractor owner. But don’t bother to call an expensive service right away; check your cooling system first. It may be only a stubborn air bubble; follow this guide, and you will learn how to bleed your tractor’s coolant system with ease.

Why Bleeding Your Tractor’s Coolant System is So Important

Bleeding the cooling system is the critical final step after replacing a hose or changing the coolant. When you drain the system, air inevitably gets trapped in the high points of your tractor’s complex plumbing. This trapped air forms a stubborn bubble, or an “air lock,” that acts like a blockage, preventing coolant from circulating effectively. This leads to serious, and often costly, consequences:

- Catastrophic Engine Overheating: This is the biggest danger. The trapped air allows extreme hot spots to form inside the engine, which can quickly lead to a warped cylinder head or a blown head gasket.

- No Heat in the Cab: A classic symptom. If your heater is only blowing cold air, it’s a telltale sign of an airlock in the heater core.

- Inconsistent Performance: An air pocket passing over the temperature sensor can cause the gauge to fluctuate wildly, potentially tricking the engine’s computer (ECU) and leading to poor performance.

By bleeding the air out, you ensure the coolant can do its job, protecting your engine and keeping your tractor ready for any task.

First, Identify Your Tractor’s Cooling System

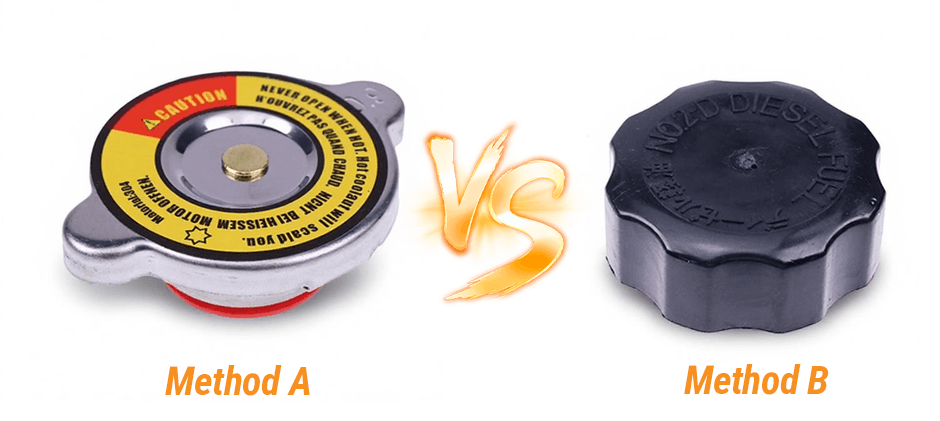

Before you begin, look at your tractor. This will determine which guide you follow.

- Traditional Radiator Cap: Does your tractor have a removable metal cap directly on the top of the radiator? If YES, proceed to Method A.

- Pressurized Reservoir (Degas Bottle): Does your tractor have a sealed plastic tank (usually white or semi-transparent) where you add coolant, with no cap on the radiator itself? If YES, proceed to Method B.

If you have other questions about the cooling systems, you can check the 11 Cooling System Components to Check When Your Heavy Engine Overheats.

Method A: For Tractors with a Traditional Radiator Cap

This section covers the professional method using a funnel and a field-expedient alternative.

Part 1: The 8-Step Guide

This process is straightforward and highly effective, especially when using the right tool for the job.

Tools You’ll Need:

- The Correct Coolant: Check your tractor’s manual.

- Spill-Proof Funnel Kit: This is the most important tool.

- Safety Glasses and Gloves.

The Step-by-Step Guide

Step 1: Safety Preparation & Positioning

Safety always comes first. Ensure your tractor’s engine is completely cool. Park the tractor on level ground; if possible, position the front wheels on a slight incline. This makes the radiator neck the highest point in the system, helping air escape more naturally.

Step 2: Remove the Radiator Cap

After confirming the engine is cool, wrap the radiator cap with a thick rag and slowly turn it counter-clockwise a half-turn to release any residual pressure. Then, fully unscrew and remove the cap.

Step 3: Install the Spill-Proof Funnel

From your spill-proof funnel kit, select the adapter that creates a perfect seal on your radiator’s filler neck. A stable funnel is key to a successful operation.

Step 4: Fill with Coolant

Pour the correct, pre-mixed coolant into the funnel in a slow, steady stream. Continue filling until the funnel itself is about one-third full. The weight of this column of coolant helps push trapped air out.

Step 5: Start the Engine & Set the Heater

Start the tractor’s engine and let it idle. Enter the cab and set the heater to its highest temperature setting and the fan to high. This is a crucial step that opens the valve to the heater core, allowing coolant to circulate through the entire system.

Step 6: Monitor the System & Purge the Air

Watch the coolant in the funnel. You will see air bubbles rising and “burping” out. Once the engine reaches operating temperature (the large upper radiator hose will be hot), you can occasionally and gently raise the engine speed to around 1500 RPM to help dislodge stubborn air pockets.

Step 7: Shut Off the Engine & Allow to Cool

When you haven’t seen any new bubbles for several minutes, the air has been mostly purged. Shut off the tractor’s engine and patiently wait for it to cool down completely. As the coolant’s temperature drops, its volume will contract, causing the level to decrease.

Step 8: Final Top-Off and Inspection

Once the engine is fully cool, use the stopper from your funnel kit to cleanly remove the funnel. Check the coolant level inside the radiator and top it off if necessary. Securely replace the radiator cap and fill the separate plastic reservoir/overflow tank to the “Full Cold” line.

Part 2: How to Bleed Your Tractor’s Coolant System without a Spill Funnel

If you’re in the field without proper tools, this technique uses gravity to your advantage.

- The Positioning: Park your tractor on a steep, safe incline. The goal is to make the radiator neck the absolute highest point of the entire cooling system.

- The Process: With the engine cool, remove the radiator cap and let the tractor idle with the heater on full blast. As air “burps” out of the radiator neck, be prepared for hot coolant to splash. Carefully add coolant in between these burps to keep the level up. You can significantly speed up the process by repeatedly squeezing the large upper radiator hose, which manually forces trapped air pockets toward the opening.

- The Critical Follow-Up: This method may not remove 100% of the air on the first try. After the heater blows hot, cap the system. It is essential to run the tractor for a day, let it cool down completely, and then re-check and top off the coolant level.

Method B: How to Bleed Your Tractor’s Coolant System Without a Radiator Cap

Many modern tractors use a pressurized reservoir (or degas bottle). The process relies on the system’s natural circulation.

- The Setup: With the engine cool, remove the reservoir cap. Start the tractor and immediately set the cab heater to its maximum heat and the fan on high.

- The Process: Let the tractor idle. As it warms up, air will be purged from the engine and heater core, appearing as bubbles in the reservoir. Your main task is to ensure the coolant level does not drop below the “Full Cold” line as the air escapes. As the engine warms up, the level will naturally rise. Once the heater blows hot and the bubbling stops, allow the engine to cool completely, then perform a final top-off to the “Full Cold” line.

- Confirmation: The most reliable sign that the air is gone is when your heater begins to blow consistently hot air. Once the bubbling stops, shut the engine off, allow it to cool down completely, and perform a final top-off before securing the cap.

Common Issues & Troubleshooting

Problem 1: The bubbles just won’t stop.

A constant stream of very small bubbles after the engine is warm can be a sign of a leaking head gasket. This means exhaust gas is being forced into your cooling system. If you suspect this, a professional diagnosis is the next step.

Problem 2: My tractor still overheats after bleeding.

If you’re certain all the air is out, you likely have a faulty component. The top suspects are:

- A Bad Thermostat that is stuck closed.

- A Failing Water Pump with a worn internal impeller.

- A Clogged Radiator (either externally with debris or internally with sludge).

5 Tips to Maintain Your Tractor’s Cooling System

- Check Levels Before Every Use: A glance at the overflow tank can save you from a major failure.

- Inspect Hoses for Wear: Look for cracks, soft spots, or bulges.

- Use the Right Coolant: Never mix different types or colors of coolant.

- Keep the Radiator Screen Clean: Regularly blow it out with compressed air.

- Replace Wear Parts Proactively: A thermostat and radiator cap are cheap insurance against an expensive engine repair.

Keep Your Tractor Working Cool with Reliable Parts

Now that you’ve learnt how to bleed your tractor’s coolant system, from pre-identification to maintenance tips. But it’s only the first step. The true long-term reliability often depends on components functioning well, including the thermostat, water pump, or radiator cap, etc.

To get a reliable parts supplier, FridayParts is your wise choice. We stock a huge range of cooling system components for major tractor brands. Visit our website today to find the perfect tractor parts, enjoy a one-year warranty & a 90-day return period to ensure your tractor works long and strong!