Bobcat fault codes are a sign reminding you that something in your machine is wrong. If you learn the code and symbols’ meaning, you can often find the problem faster and avoid serious damage and costly downtime. This guide explains Bobcat fault codes in simple words, lists common code groups, and tells you what to check first.

What Are Bobcat Fault Codes?

Bobcat fault codes are Diagnostic Trouble Codes (DTCs) created by the machine’s main controller (often called the ECU). A code appears when a sensor, switch, wire, or system sends a reading that is outside the normal range.

Think of a fault code as a clear message, not just a basic warning light. It helps guide you to the area that needs attention.

How Do I Read Bobcat Fault Codes?

Reading a Bobcat fault code is easier once you know the format. The codes use a letter, a two-digit number, a hyphen, and another two-digit number (example: M01-10).

The first letter is your biggest clue because it tells you which system is reporting the problem. That helps you know where to start checking.

Understanding the Code Structure

The first letter is your main clue:

- M codes (Main Controller): Come from the main controller and relate to key machine systems.

- W codes (Warning): A warning. The machine may still run, but you should check the issue soon.

- D codes (Display): Related to the instrument panel/display. This can mean a communication problem between the display and the controller, or a fault inside the display unit.

- A codes (Attachment): Related to the attachment control system.

- H codes (HVAC): Related to the heating, ventilation, and air conditioning system.

For engine-related codes, the cause may be a sensor, wiring, a fuel/air problem, or a failed part. Bobcat machines use engines from different makers (such as Kubota, Doosan, or Perkins), so it’s important to match the correct engine model and part number when replacing parts. The wrong part can make the code come back.

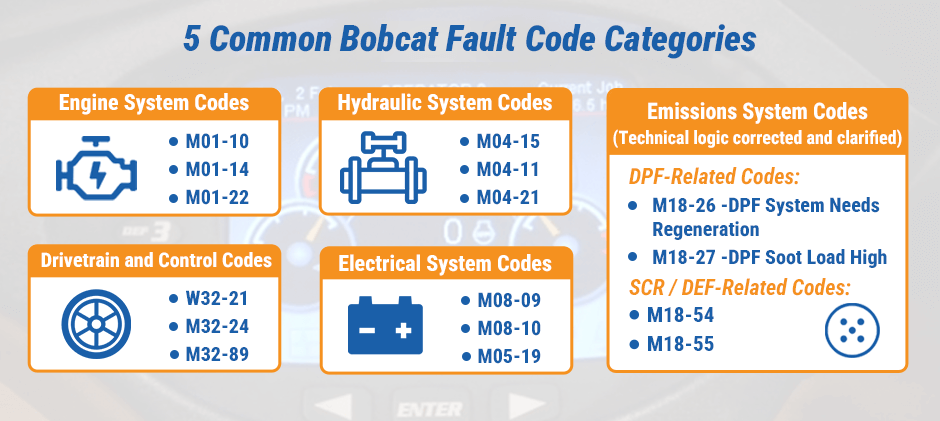

5 Common Bobcat Fault Code Categories

Bobcat machines can show many different codes, but most fit into a few main groups. Here are five common categories you may see.

1. Engine System Codes

Engine codes are some of the most serious. They can warn you about oil pressure, coolant temperature, fuel delivery, and air intake problems. Ignoring them can cause major engine damage.

Common examples (Code format and severity corrected):

- M01-10 – Low Engine Oil Pressure (Shutdown Event): This is a critical fault that will shut down the engine to prevent catastrophic failure.

- M01-14 – High Engine Coolant Temperature (Shutdown Event): This is also a critical fault that triggers an engine shutdown to prevent overheating.

- M01-22 – Fuel Level Sensor Error

2. Hydraulic System Codes

Hydraulics are the “muscle” of the machine. These codes can point to low/incorrect pressure, hot hydraulic oil, or blocked filters. Fixing these early helps keep lift power strong and controls working correctly.

Common examples (Code format corrected):

- M04-15 – Hydraulic Charge Filter Plugged

- M04-11 – High Hydraulic Oil Temperature

- M04-21 – Hydraulic Lockout Solenoid Error

3. Electrical System Codes

Electrical codes can be frustrating, but they are useful. They often point to battery voltage, the charging system, or communication problems between controls and sensors.

Common examples (Code format corrected):

- M08-09 – High Battery Voltage

- M08-10 – Low Battery Voltage

- M05-19 – Joystick Communication Error

Tip: Voltage problems are often caused by a weak battery, dirty terminals, a loose ground, or a failing alternator—so always check the basics first.

4. Drivetrain and Control Codes

These codes can change how the machine drives and how the controls feel. They may involve joysticks, speed sensors, solenoids, transmission functions, or the parking brake. These systems matter for safe operation.

Common examples (Code format corrected):

- W32-21 – ACS/SJC Controller Not Programmed

- M32-24 – Two-Speed Solenoid Error

- M32-89 – Parking Brake Solenoid Error

5. Emissions System Codes

Newer Bobcat machines use emissions systems—mainly the DPF (Diesel Particulate Filter) for soot and the SCR (Selective Catalytic Reduction) system, which uses DEF (Diesel Exhaust Fluid). These are different systems, and they use different codes.

DPF-Related Codes:

- M18-26 – DPF System Needs Regeneration: A prompt to run a “regen” cycle to burn off built-up soot.

- M18-27 – DPF Soot Load High: A more serious warning that soot levels are high, which may lead to reduced engine power.

SCR / DEF-Related Codes:

- M18-54 – DEF Level Low: A warning to refill the DEF tank soon.

- M18-55 – DEF Level Critically Low: A severe warning that will cause major power reduction and may stop the engine from restarting after shutdown.

What Should I Do When a Code Appears?

First, think safety. If the code is a critical engine or hydraulic warning (like low oil pressure or high temperature), stop work right away and park in a safe place.

Write the code down exactly (letters and numbers). One wrong digit can lead to the wrong diagnosis.

Check the simple, common causes first:

- Low fluids (engine oil, coolant, hydraulic oil, DEF)

- Clogged filters (air, fuel, hydraulic)

- Blocked radiator/coolers (mud, dust, debris)

- Loose electrical plugs/connectors

- Damaged wires (rubbed-through spots)

- Weak battery or corroded battery terminals

A good rule from experienced operators:

“That code isn’t a suggestion; it’s a command. Stop, write it down, and figure it out before you cause a thousand-dollar problem.”

After you identify the code, follow the operator’s manual for the correct checks and test procedures. If you fix the root cause, the code will usually clear by itself—or it can be cleared using the proper procedure for your model.

Conclusion

Bobcat fault codes help you know what your machine needs faster. When a code appears, record it, do basic checks, and don’t keep working if the code points to a serious risk. When necessary, you should turn to a technician. If you need to replace parts, FridayParts offers a range of high-quality aftermarket Bobcat parts for whatever you need. Please always match the correct machine model, engine model, and part number to prevent repeat faults and extra downtime.