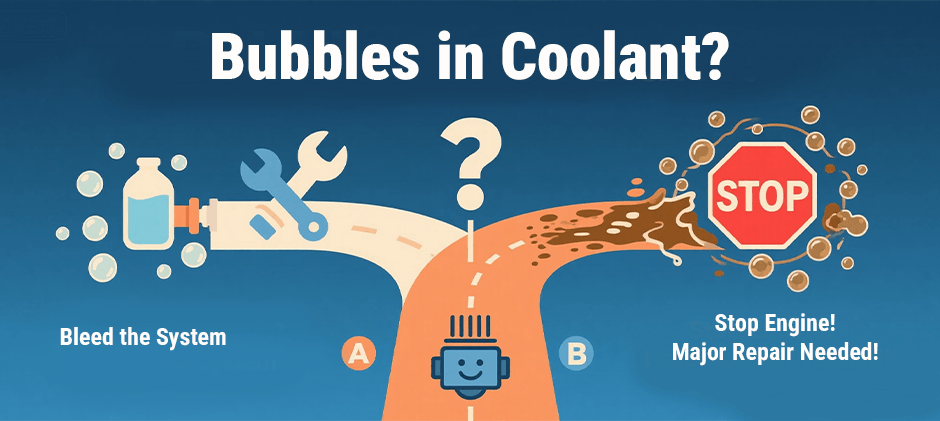

When finding the bubbles in your cooling system, don’t panic. Firstly, you need to identify what it is caused by: is it caused by air & gases in the cooling system? You can identify this by several specific symptoms. Then, decide what your machinery needs: a simple bleed or an overhaul of your engine, and follow the step-by-step bleeding guide. Follow this article, and you will know what to do rather than be confused.

Air or Exhaust Gases: How to Differentiate?

Before looking at symptoms, it’s crucial to understand the source. The diagnosis for air & gases in the cooling system depends entirely on what is trapped in your coolant.

- Trapped Air: This is atmospheric air that has been introduced into the sealed cooling system from an external source. It’s often a maintenance-related issue and, while problematic, is usually fixable without major engine work. If it’s a small amount of air, the system may even “burp” it out naturally over a few heat/cool cycles.

- Exhaust Gases: This is high-pressure gas from the engine’s combustion chamber being forced into the cooling system through an internal breach. This is not air and is a definitive sign of a serious mechanical failure. It will not go away on its own and will cause rapid and severe damage if ignored.

What Causes Air & Gases in the Coolant System?

Knowing the potential causes is the first step in diagnosing the source of air & gases in the cooling system.

Common Causes of Trapped AIR:

- Improper Coolant Service: This is the most common cause. When coolant is drained and refilled, air can easily become trapped if the system is not bled correctly.

- Faulty Pressure Cap: The radiator or surge tank cap is designed to hold the system under a specific pressure. A weak or damaged cap can allow air to be drawn in as the engine cools and the coolant contracts.

- Leaking Hoses or Clamps: A small leak, especially on the suction side of the water pump, can draw air into the system without necessarily causing a major, visible coolant drip.

- Failing Water Pump Seal: A worn seal on the water pump can sometimes allow small amounts of air to be pulled into the system.

Common Causes of EXHAUST GASES:

- Failed Head Gasket: This is the most frequent culprit, allowing combustion pressure to breach the coolant passages surrounding the cylinder.

- Cracked Cylinder Head or Block: A more severe failure, a physical crack creates a direct path for exhaust gases to enter the coolant jackets.

- Failed EGR Cooler: On modern diesel engines, the EGR cooler uses engine coolant to lower the temperature of exhaust gases. If this cooler fails internally, it creates a direct, high-pressure leak of exhaust into the cooling system.

4 Symptoms of Trapped Air in the Cooling System

If you have simple air pockets, the symptoms are typically related to poor coolant circulation and are less severe.

- Fluctuating Temperature Gauge: The temperature gauge may swing erratically. As an air pocket passes the temperature sensor, it gives a false reading, causing the needle to drop suddenly before rising again when coolant flow resumes.

- Poor Cab Heater Performance: The heater core is often one of the highest points in the cooling system, making it a prime spot for air to get trapped. If your cab heater is blowing lukewarm or cold air even when the engine is at operating temperature, an airlock is a likely cause.

- Gurgling Sounds: You may hear audible gurgling or bubbling sounds from the engine bay or near the heater core as the mixture of coolant and air circulates.

- Coolant Pushed to the Overflow Tank: A large air pocket will expand significantly when it gets hot, displacing coolant and pushing it into the overflow reservoir. However, the system pressure will not be excessively high.

5 Symptoms of Exhaust Gases in the Cooling System

Exhaust gases introduce extreme pressure and indicate a serious failure. The symptoms are far more aggressive.

- Rapid and Severe Overheating, Especially Under Load: This is the number one sign. The immense pressure from the combustion chamber displaces large volumes of coolant, causing the engine to overheat very quickly, particularly when working hard.

- Constant, Vigorous Bubbling in the Coolant Reservoir: This isn’t a gentle burp. It looks like a jacuzzi, with a continuous stream of bubbles appearing in the surge tank or radiator fill neck. The bubbling will often increase dramatically when you rev the engine.

- “Hard” Radiator Hoses: The cooling system becomes over-pressurized far beyond its design limits. The large radiator hoses will feel rock-solid and extremely firm to the touch, even shortly after starting the engine.

- Unexplained Coolant Loss with No Visible Leaks: The system’s extreme pressure forces coolant out of the pressure cap and overflow, making it seem like the coolant is vanishing.

- White Smoke from the Exhaust: If the head gasket breach is severe, coolant can be drawn back into the cylinder on the intake stroke and burned, producing thick, sweet-smelling white smoke from the exhaust pipe.

Key Differences Overview

This table summarizes how to differentiate between air & gases in the cooling system based on their distinct symptoms.

| Key Difference | Airlock | Exhaust Gases |

|---|---|---|

| Origin | External – Enters during maintenance | Internal – Leaks from the engine |

| Nature | Static & Trapped – A one-time issue that can be removed. | Dynamic & Continuous – Constantly forced into the system while the engine runs. |

| Key Symptom | Poor heater performance; Gurgling sounds. | Violent, continuous bubbling in the reservoir; Rock-hard hoses. |

| Severity | Minor Maintenance Problem | Critical Engine Failure Warning |

| Solution | Bleed the System | Engine Repair Required (Cannot be “bled” out) |

How to Get Air Out of a Heavy-Duty Cooling System

If your diagnosis points to a simple airlock, you can bleed the system. Safety First: NEVER attempt to open a hot cooling system. The pressurized coolant can cause severe burns.

1. Position the Machine

If possible, park the machine with the front end facing uphill. This encourages air to travel to the highest point of the system, usually the radiator or surge tank.

2. Locate Bleeder Valves

Consult your machine’s service manual to locate any bleeder screws. These are normal on the thermostat housing, heater lines, or other high points in the system.

3. Fill the System

With the engine cold, remove the pressure cap. Using a spill-free funnel is wise to prevent messes and make the process easier. Slowly fill the system with the correct 50/50 coolant mixture.

4. Start the Engine and Circulate

Start the engine and turn the cab heater on to its highest heat and fan setting. This ensures the valve to the heater core is open. Let the engine idle.

5. Bleed the Air

As the engine warms up, you will see bubbles coming up into the funnel. Once the engine reaches operating temperature (the thermostat opens and the upper radiator hose becomes hot), carefully open the highest bleeder screw. Let it hiss until a steady, bubble-free stream of coolant emerges, then close it. Repeat for any other bleeder screws, working from the lowest to the highest.

6. Rev the Engine

Gently rev the engine to 1500-2000 RPM for 20-30 seconds at a time. This helps dislodge any stubborn air pockets. You will likely see another rush of bubbles in the funnel.

7. Top Off and Cool Down

Continue idling and revving until no more bubbles appear. Ensure the coolant level in the funnel remains high. Once done, shut off the engine, let it cool completely, remove the funnel, and top off the coolant in the reservoir to the correct level. Reinstall the pressure cap.

For more detailed methods, you can read: How to Bleed Your Tractor’s Coolant System.

Final Words

Differentiating the bubble caused by air or gases is always the first and most important step. Getting this wrong can be a very costly mistake. By understanding the different symptoms, you can know exactly what you need to do next: bleed your cooling system or do an overhaul repair of your engine immediately.

Follow this guide carefully, and it can help you avoid a minor mistake turning into a catastrophic financial loss. FridayParts is here to help. We offer a range of high-quality cooling system components to cater to your demand. If you have any questions, you can also ask FridayParts for help. Our expert team is ready to offer assistance at any time you need it, and we promise to reply to your email within 24 business hours.