For equipment operators living in the southern parts of the US, we are not strangers to the summer heat wave. A functioning AC system isn’t just about comfort; it’s about maintaining focus and productivity in demanding work environments. When your car starts heating up, the AC compressor is often the first component that comes to mind. Knowing how to identify a bad AC compressor can save you downtime and costly repairs. This in-depth guide will walk you through the telltale signs and common causes of compressor failure, helping you determine if it’s time for a replacement.

Don’t know how to replace the compressor? Check FridayParts 16 Easy Steps guide to change the AC compressor!

Understanding AC Compressor

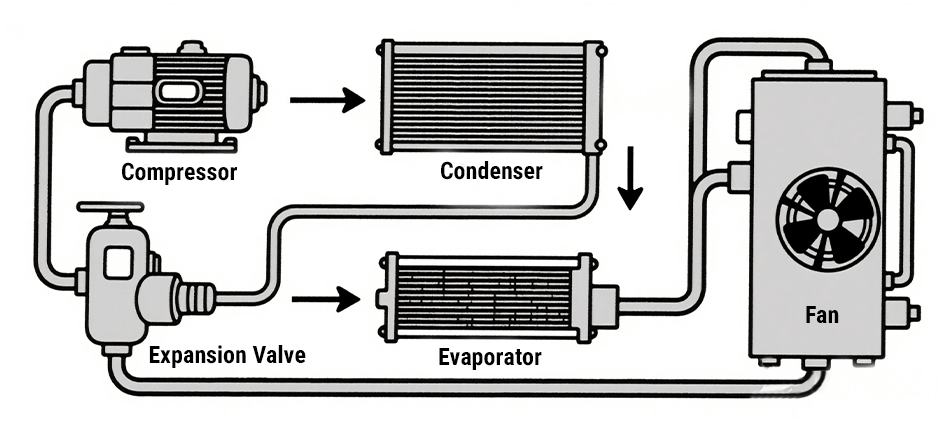

Before diving into symptoms, let’s quickly review what the AC compressor does. Think of it as the heart of your heavy equipment’s air conditioning system. Its main job is to compress the refrigerant gas, increasing its temperature and pressure. This compressed refrigerant then moves through the system, releasing heat outside the cab and absorbing heat from inside, eventually providing cool air. Without a working compressor, the refrigerant cannot circulate properly, and your AC won’t cool.

Key Indicators of a Bad Air Conditioning Compressor

Several symptoms can point to a failing or bad AC compressor. Pay close attention to these signs during your daily operations or routine checks.

1. No Cool Air or Warm Air from Vents

This is arguably the most obvious sign. If your AC is blowing air that feels warm, or simply not as cold as it used to be, the compressor is likely failing to pressurize the refrigerant effectively. The system might be running, and the fan might be blowing, but the crucial cooling process isn’t happening.

2. Unusual Noises from the AC Unit

A healthy AC compressor operates with a consistent, low hum. Any sudden changes in sound should raise a red flag. Listen for:

- Grinding or Rattling: These noises often suggest internal damage to the compressor’s components, such as worn bearings or pistons.

- Clicking or Clunking: While a single click is normal when the compressor clutch engages, continuous clicking or loud clunking can indicate issues with the clutch itself or significant internal problems.

- Hissing: A hissing sound might point to refrigerant leaks, particularly if heard around the compressor seals or hoses.

3. Reduced Airflow from Vents

Even if some cool air is coming out, if the airflow seems weaker than usual, your compressor might be struggling. A failing compressor can’t adequately move the refrigerant, which impacts the overall system pressure and airflow.

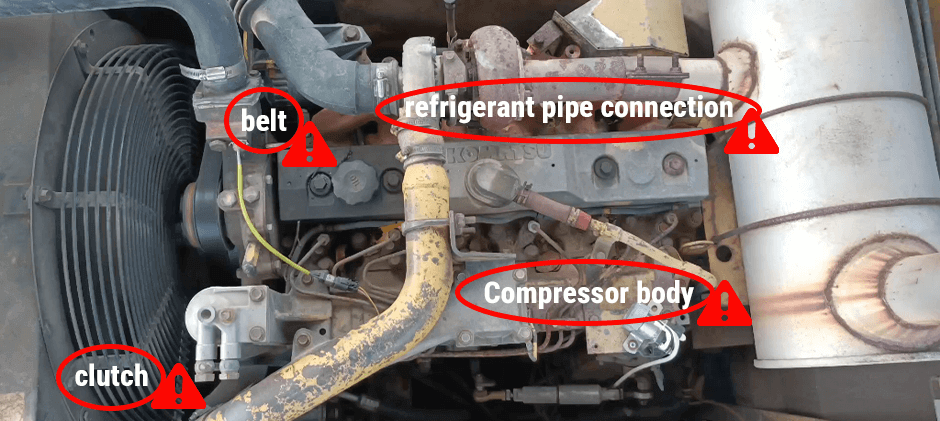

4. AC Compressor Clutch Not Engaging

The compressor clutch is a critical part that connects the compressor to the engine’s power. When you turn on the AC, you should hear a distinct click as the clutch engages and see the outer part of the pulley spin with the inner part.

- If the clutch doesn’t engage at all, the compressor isn’t receiving power or is internally seized.

- If it engages but then disengages quickly, or makes a screeching sound upon engagement, it could be a sign of low refrigerant (which triggers a safety shut-off) or a failing clutch bearing.

5. Frequent Tripping of the Circuit Breaker (Heavy Equipment Specific)

Heavy equipment AC systems are robust, but a failing compressor can draw excessive electrical current. This overload can cause the circuit breaker protecting the AC system to trip repeatedly. If you find yourself constantly resetting the breaker when you try to use the AC, it’s a strong indicator of an electrical issue within the compressor.

6. Visible Leaks Around the Compressor

Inspect the compressor and the surrounding hoses for any oily residue or wet spots. Refrigerant often contains a small amount of oil, so a leak will leave a visible mark.

“A small leak in your AC system can quickly turn into a major compressor failure if ignored. Regular inspections are key.”

7. Increased Fuel Consumption

While not always immediately obvious, a failing compressor can make your engine work harder to maintain the desired cabin temperature. This added strain can lead to a noticeable increase in fuel consumption, particularly in heavy machinery where engine load is already high.

Common Causes of Compressor Failure

Knowing what causes AC compressor failure can help prevent future issues and guide your troubleshooting.

- Normal Wear and Tear: Like any mechanical component, compressors have a lifespan. Years of continuous operation in dusty, vibrating heavy equipment environments will eventually wear down internal parts.

- Refrigerant Leaks: Low refrigerant levels force the compressor to work harder, leading to overheating and premature failure. Leaks also allow moisture and air into the system, causing corrosion.

- Contamination in the Refrigerant System: Debris, metal shavings from worn components, or moisture can circulate within the refrigerant, causing blockages and damaging the compressor’s internal parts.

- Improper Charging or Maintenance: Incorrect refrigerant levels (over or under-charged) or using the wrong type of refrigerant or oil can severely damage the compressor. Failing to replace the drier/receiver or properly evacuate the system during service also introduces contaminants.

- Electrical Issues: Problems with wiring, relays, fuses, or the compressor’s electrical windings can prevent it from starting or cause it to overheat.

- Clutch Failure: A worn or damaged compressor clutch can lead to the compressor not engaging, or it can put undue stress on the compressor itself.

When to Replace the Compressor (Summary Chart)

Determining if your AC compressor needs to be replaced depends on the diagnosis.

| Symptom Category | Specific Indicators | Implication | Replacement Likely? |

|---|---|---|---|

| Cooling Performance | No cool air, blowing warm air, very reduced cooling | Compressor not circulating refrigerant effectively or completely failed. | High |

| Noises | Loud grinding, clunking, constant clicking | Severe internal damage, worn bearings, seized components. | High |

| Electrical | Repeated circuit breaker trips, compressor won’t start | Internal electrical short, severe overload. | High |

| Physical Damage | Visible cracks, large refrigerant leaks (oily residue) | Structural integrity compromised, significant internal issue. | High |

| Clutch Issues | Clutch won’t engage, makes screeching noise | Could be clutch repairable, but often signals underlying compressor issue. | Moderate to High |

Conclusion

Don’t let a bad Air Conditioning compressor keep you down! Early recognition of the bad part could give you back a nice and comfortable operating cabin. By paying attention to the signs like warm air, strange noises, reduced airflow, and electrical issues, you can quickly pinpoint the problem. While some minor issues might be repairable, severe symptoms often point to the need for a new compressor. When it comes to sourcing replacement parts for your heavy equipment, look no further. At FridayParts, we offer high-quality aftermarket AC compressors at affordable prices, with a vast inventory and wide compatibility for many heavy equipment brands. Don’t let a failing AC slow you down – browse our selection today and get your cab cooling efficiently again!