The fuel filter cleans out dirt and contaminants before fuel gets to the engine. On construction sites or in the great outdoors, fuel quality and working conditions are way tougher. That’s why the fuel filter does a way bigger job than most operators think. So, where is the fuel filter located on the machine? Knowing this helps you check and maintain it properly.

Where Is the Fuel Filter Often Located?

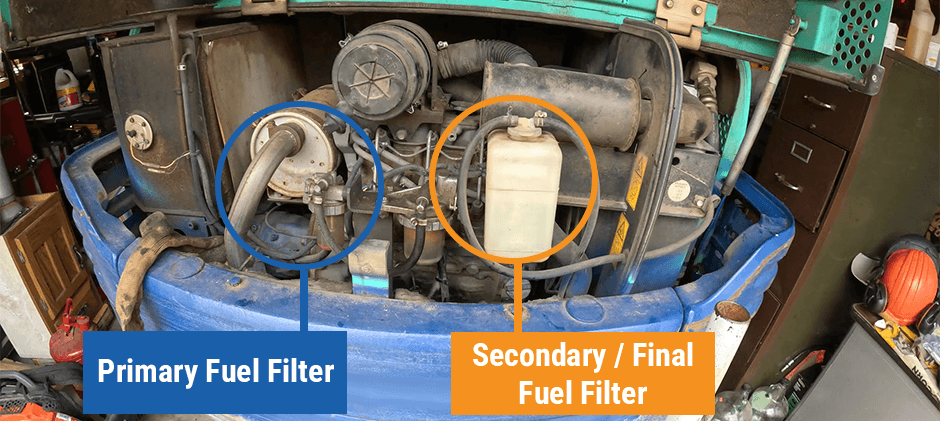

Heavy-duty off-road machines like excavators, dozers, and wheel loaders almost always use a multi-stage filtration system. Because diesel engines are sensitive to dirt and water in the fuel. Know this system, and you’ll know where to find your filters. You’re basically looking for two main ones.

Primary Fuel Filter / Water Separator

This is the first stop for fuel after it leaves the tank. Its main job is to catch big chunks of debris—and most importantly, split water away from the diesel. It’s a canister-style filter, usually with a clear plastic or glass bowl on the bottom. The bowl lets you see if water has built up—you’ll spot it as a separate layer under the diesel. There’s a small drain valve or petcock at the bottom of the bowl to drain the water out.

Common spot: You’ll usually find it bolted to the machine’s frame or chassis, somewhere between the fuel tank and the engine. It’s made to be easy to get to, since you need to check for water all the time.

Secondary (or Final) Fuel Filter

After fuel goes through the primary filter, it heads to the secondary one for a final, super-fine clean. Only then does it go into the high-pressure fuel injection pump and injectors. It’s usually a spin-on metal canister—looks a lot like an oil filter, but it’ll often say “Fuel” on it. No clear bowl here, because its job is to catch tiny particles, not large amounts of water. Some machines also have a third filter inside the fuel tank. It’s called a “sock” and works as a pre-filter, but you don’t need to service it very often. The primary and secondary filters are the ones you’ll be taking care of on a regular basis.

Common spot: This one’s almost always mounted directly on the engine block. Look for it near the fuel injection pump, or along the fuel lines on the side of the engine.

How to Find the Fuel Filter on Your Machine?

Now that we know where these filters are usually found, let’s talk about how to find the exact ones on your machine. The general spots are the same, but every brand sets things up a little differently.

First, check your machine’s operator or service manual. This is hands down the most reliable source of info. The manual has diagrams and step-by-step guides that show exactly where all the service parts are—including both the primary and secondary fuel filters. If you don’t have the manual handy, use this simple trick: trace the fuel lines.

- Start at the fuel tank: Pop open the main engine covers or hoods to get a good look at the engine and the parts around it. Find your fuel tank.

- Follow the fuel line: Spot the thick fuel line coming out of the tank—it’s usually about 1/2 to 3/4 inch wide. Follow this line toward the engine.

- Find the primary filter: The first canister-shaped part you hit along this line is definitely the primary filter/water separator. It’s usually bolted to the frame or the inside wall of the engine compartment.

- Track down the secondary filter: From the primary filter, keep following the fuel line as it runs to the engine. This line will hook up to the secondary filter, which screws right onto a housing on the engine block. It’s often close to other parts you service regularly.

Finding these filters is step one for proper fuel system maintenance. And this task directly affects how well your machine runs and how long it lasts. Your engine gives you hints. If it loses power when you’re working it hard, that’s the engine yelling for clean fuel.

What Are the Signs of a Bad Fuel Filter?

A clogged fuel filter rarely craps out all of a sudden. It chokes off fuel flow little by little, and gives you plenty of warning signs before it shuts your machine down completely. Spotting these early can save you from being stuck dead in the water on the job site.

- Loss of engine power: When you put the machine under heavy load—like digging into a hard pile or climbing a steep hill—the engine might feel weak or bog down. That’s because the clogged filter can’t feed the engine all the fuel it needs to get the job done.

- Sputtering or rough idle: A blocked filter messes up the steady fuel supply, making the engine run all wonky. You might hear it sputter, misfire, or idle unevenly.

- Hard starting or no start at all: If the filter’s really clogged, it won’t let enough fuel reach the engine to fire it up. The engine might crank and crank, but it won’t turn over. This happens a lot more in cold weather, since diesel fuel gets thicker when it’s chilly.

- Higher fuel use: When the engine’s starved for fuel, its ECU will try to make up for it by adjusting other settings. That leads to inefficient burning—and you’ll notice you’re burning through fuel way faster than usual to get the same work done.

- Engine warning lights: Modern excavators and loaders have sensors that keep an eye on fuel pressure. If pressure drops too low because of a clogged filter, it’ll trigger a check engine light or a specific fuel system warning on your dashboard.

These signs are impossible to ignore—you gotta pay attention. Running a machine with a clogged fuel filter doesn’t just kill performance, it also puts huge strain on the fuel pump. And fixing a busted pump will cost you a whole lot more than a new filter.

Tips on How to Replace the Fuel Filter Safely

Changing a fuel filter is an easy maintenance job, but doing it right is super important for your diesel engine’s health. Rushing through it or skipping steps can let air or dirt into the fuel system—and that’ll cause big problems. Here are our top tips for a safe, solid filter replacement.

- Let fuel system pressure die down: Before you loosen any lines, shut the machine off and let it sit for a bit. That lets pressure fade away on its own. Some systems have a special bleed screw for this, but just waiting is usually enough and safer.

- Clean the area really well: Dirt and grease are everywhere around the filter housing. Don’t touch the old filter yet—grab a degreaser and either compressed air or clean rags, and wipe down the filter and its mounting head completely. This keeps debris from falling into the clean part of the fuel system when you take the old filter off.

- Fill the new filter before installing it: Always pour fresh, clean diesel into the new secondary fuel filter before screwing it on. An empty filter forces the system to clear out a ton of air—that’s a hassle and wears out the injection pump. Pre-filling cuts down on how much air you have to bleed later. Only use spotless fuel from a clean, dedicated container for this step.

- Prime the fuel system: After putting the new filter(s) on, you have to prime the system to get rid of leftover air. Find the small manual hand-priming pump—it’s usually on top of the primary or secondary filter housing. Pump it until it feels firm. That means the filter is full and the system has pressure.

- Safety first: Wear nitrile gloves and safety glasses to keep diesel off your skin and out of your eyes. Work in a well-ventilated spot, and keep a fuel-rated fire extinguisher close by just in case.

Summary

Most off-road machines use a two-stage fuel filtration system. It usually includes a primary water separator and a secondary fuel filter. Knowing this setup helps you spot these parts faster, so you can inspect and maintain them the right way. For regular maintenance, check the filters often for water or dirt build-up. And replace them on time—follow the schedule the machine maker recommends.

Fuel filters are wear-and-tear parts. Keeping the right replacement filters on hand cuts down on machine downtime big time. FridayParts has a wide range of fuel filters for heavy-duty equipment. They’re reliable, reasonably priced, and perfect for daily maintenance and spare parts stockpiling.