On construction sites, in agriculture, in demolition, or in any workplace where materials are loaded or transported, you will find a wheel loader working with a hard run. The wheel loader is a huge moving shovel and is very popular, so many top heavy equipment manufacturers make wheel loaders. That means you have many options, but are puzzled about what is best for you. We are here to provide some popular wheel loader models and brands for your reference.

What Is a Wheel Loader?

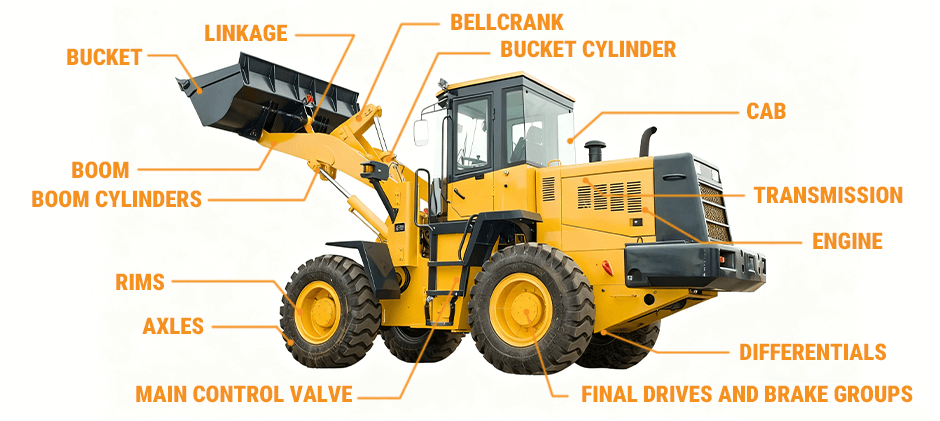

A wheel loader is essentially a versatile heavy equipment, characterized by a four-wheel drive system and front-loading buckets. Its main work is earthworks —scraping, handling, and loading loose materials such as sand, earth, rubble, and debris. Unlike crawler loaders, their durable tires give them excellent maneuverability on roads and dressed surfaces such as asphalt or concrete without causing damage. This mobility makes it a must-have on many work sites.

While wheel loaders share similarities with skid steer loaders, they are generally superior in size, power, and capacity. Compact wheel loaders are often the ideal solution if project requirements exceed the capabilities of skid steer loaders. The machines have many sizes, from compact models under 10,000 pounds to large mining models weighing over 500,000 pounds. Wheel loader size can be divided into 4 main categories: compact, small, medium, and large. Knowing these categories is the first step towards narrowing down your options.

What Are Compact and Small Wheel Loaders?

Compact and small wheel loaders are most used in the garden, agriculture, residential construction, and equipment rental industries. They are small and occupy less space, and have several obvious advantages: they are more fuel efficient, they cause little damage to soft ground such as lawns, they also have a wider field of vision for drivers, and they also have the flexibility to enter and exit narrow places. As a reminder, the definitions of “compact” and “small” may not be the same for different brands, so it’s better to look at the specific working weight and horsepower.

What Are Common Compact Wheel Loaders Models and Brands?

Compact loaders are small, quick, and easy to handle. They’re great for jobs where you need to work in tight spaces. Here are some common models in this group:

- Caterpillar 906M

- John Deere 244L, 324L

- Kubota R430

- Bobcat L65, L85

- Case 321F

- Wacker Neuson WL95

What Are Small Compact Wheel Loaders Models and Brands?

Compared to compact loaders, small loaders have more power and can carry heavier loads. They’re good all-around machines for construction and moving materials. Some popular models are:

- Caterpillar 926M

- Bobcat L23, L28

- Kubota R540, R640

What Are Medium and Large Wheel Loaders?

Medium wheel loaders generally have buckets between 3 and 5 yards in length and are more capable of handling much heavier material than small and compact loaders. They dig, load, handle, and level the ground, so they are common in construction, quarrying, gardening, logging, and demolition.

Large wheels are about the same as medium-sized ones, but capable of heavier work. They have buckets of about 7 to 8 yards and are particularly suitable for loading large trucks or handling heavy projects such as logging, farm operations, construction sites, garbage disposal, slag cleaning, and demolition.

What Are Medium Compact Wheel Loaders Models and Brands?

Medium, or mid-size, loaders are the backbone of many construction, quarry, and aggregate operations. They possess the power for serious digging and loading while still being transportable between job sites without extreme logistics. As these machines work harder, keeping them operational is crucial. Having a reliable source for high-quality wheel loader parts ensures that downtime is minimized. Examples of well-regarded medium loaders include:

- Komatsu WA200-8, WA270-8

- Caterpillar 950M, 980 XE

What Are Large Compact Wheel Loaders Models and Brands?

Large wheel loader models are specially built for the toughest working conditions. They work in large mines, infrastructure projects, or industrial scrapyards. Large and powerful, it can fill a large truck in just a few times, which is particularly efficient. Leading models in the large category include:

- Komatsu WA380-8, WA500-8

- John Deere 744 P-Tier, 944 X-Tier

- Volvo L70H, L350H

Specifications and Features to Consider

In addition to size and weight, there are several key factors that affect how a wheel loader will perform. Know these considerations to find the best machine for your project

Hydraulic Flow

The hydraulic system is the muscle of the wheel loader. Its unit of flow is in gallons per minute (GPM), which determines the speed and power of the attachment.

- Standard Flow (17-24 GPM): The standard flow is generally sufficient, and common attributes such as buckets and grabs are fine.

- High-Flow (30-40+ GPM): High-flow systems are more powerful and are used to drive high-power appliances, such as snow blowers, cold planers or lawn crushers. If on a standard flow system, hard band high flow is a tool, the effect is not ideal.

Load Capacity

The bucket is the most common accessory and is directly concerned with the loader’s capacity. Capacity is usually in cubic yards. Engine power, hydraulics, and overall machine weight can directly affect bucket capacity and load. When choosing a machine, make sure it can easily handle the materials you normally move.

Lift Height

The maximum lifting height of the loader is also critical. A small loader can generally lift 8 to 10 feet to put a pallet on a trailer. But in a quarry-like place, a large loader might have to lift 25 feet or more to get past the gang of a large truck. So, before choosing a machine, be sure to confirm that its lifting height can meet your work needs.

Linkage Configuration

The linkage is the set of arms that connects the attachment to the loader. There are two dominant configurations:

- Z-Bar Linkage: This is the most common kind of design. The digging force is particularly strong, very suitable for heavy work, such as digging, charging, etc. Suitable for high-strength digging and buckets.

- Parallel-Lift (or Tool Carrier) Linkage: This design allows the attribute to be kept level when lifting and lowering, and the line of sight is wider. It is very useful for tasks such as forking goods, grabbing materials, and moving things.

Frame Type: Rigid vs. Articulated

Most wheel loaders today are articulated. That means they have a joint in the middle so the machine can bend to turn. This makes the turning circle much smaller, which is super handy in tight spaces. Rigid-frame loaders are not very common now and don’t turn as easily. Some brands also make all-wheel-steer models as another option.

Attachments and Auxiliary Features

What makes a wheel loader really great is its attachment. The quick connector system lets the operator change tools quickly, so that one machine can handle all kinds of different tasks throughout the day.

- Buckets: Besides the general-purpose bucket, including multi-purpose (4-in-1), side-dump, high-dump, light material, and rock buckets.

- Forks: Pallet forks play a great role in material handling. It makes your loader into a heavy-duty forklift, good for moving pipes, lumber, and palletized goods.

- Grapples: Designed to grab and secure irregularly shaped objects, grapples can be found for a specific material, like log grapples, scrap grapples, and rock grapples.

- Blades: The loader can be equipped with attachments such as snow plows, bulldozers, and angle blades to clear snow, do light leveling, and push soil.

- Couplers: The hydraulic quick-coupler helps to quickly change attachments. The operator to turn tools from the cab in seconds, obviously improving efficiency.

Conclusion

In general, wheel loaders move things quickly and much, and are essential for many industries. Different types of loaders can have different applicable scenarios. Each with its own characteristics and common brands. No matter what model or brand you use, FridayParts has related wheel loader parts, guaranteed compatibility, and helps you easily maintain the machine.