Starting in 2010, the EPA required diesel exhaust fluid (DEF) for medium and heavy-duty equipment. So, pretty much all newer models can’t run without it. And one of the key parts of the whole system is the DEF header. But what is a DEF header? This guide will cover everything you need to know about the DEF header.

What Is a DEF?

Diesel Exhaust Fluid (DEF) is a non-toxic liquid, mostly urea and water. You don’t put it in the fuel tank – it’s sprayed into the engine’s hot exhaust fumes. When DEF goes into the SCR system, a chemical reaction takes place. It breaks down harmful NOx into harmless nitrogen gas and water vapor, cutting down emissions.

For today’s off-road machines like excavators and loaders, the SCR system and DEF are a must. If you run out of DEF or the system fails, your machine will probably slow down on its own, set off warnings, or even stop working properly. So it’s really important to keep your DEF system running well.

What’s a DEF Header?

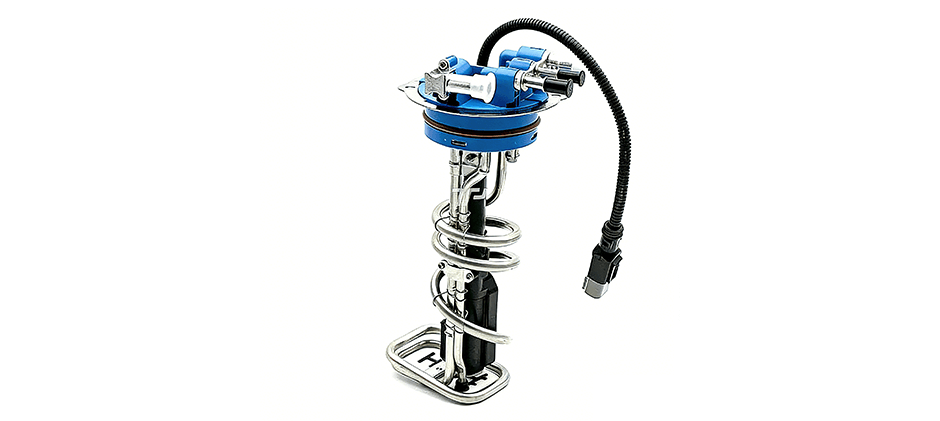

The DEF header is the control center of the whole DEF system. You might also hear it called a DEF sender unit or DEF sensor. It’s a complex L-shaped part that mounts right on top of the DEF tank, and most of it sits down inside the fluid.

Its main job is to monitor the fluid in the tank and send it to the SCR system in the right condition and amount. It’s not just a simple pickup tube. It’s a multi-function part that checks the DEF’s quality, temperature and level.

Think of the DEF head as the brain and heart of your machine’s emissions system. It detects, regulates and pumps fluid, making sure everything runs as it should. If it goes wrong, the whole operation is at risk.

How Do DEF Headers Work?

The system that sends DEF to your machine’s exhaust has three main parts: the DEF tank that holds the fluid, the DEF header inside the tank, and the SCR catalyst where the chemical reaction happens. The DEF header is the vital link between the tank and the rest of the system.

This L-shaped part is basically a set of high-tech sensors and tubes all in one unit. Its job is to make sure the fluid going to the engine is good quality, at the right temperature, and in the exact amount needed. It does this with a few key components. A level sensor tells the machine’s computer (ECU) how much fluid’s left in the tank. A temperature sensor keeps an eye on the fluid’s temp—if it gets too cold, it turns on built-in coolant lines that circulate warm engine coolant to stop the DEF from freezing. Most importantly, a quality sensor constantly checks the urea concentration to make sure it’s not contaminated or gone bad.

When you start your machine, the DEF header runs a self-check. Its sensors send the fluid’s level, temp and quality info to the ECU. Normally, the DEF pump draws the DEF up from the suction filter at the bottom and sends it to the exhaust nozzle. Once the sensor detects a problem, such as the liquid level being too low, the DEF being contaminated, or ice being frozen, the ECU will get a signal. The fault light on the dashboard will come on. In severe cases, the engine is limited to avoid damage to the equipment.

How Does Temperature Affect the DEF Header?

Temperature is one of the biggest environmental factors that affects the DEF system. The DEF header can handle a wide range of temps, but extreme weather causes problems.

- Cold weather: DEF freezes at 12°F (-11°C), like we said before. The header has built-in heating lines to thaw it, but this doesn’t happen right away. A broken thermostat or a clogged coolant line can stop the system from thawing it at all. If the ECU doesn’t get a “ready” signal from the temp and quality sensors within a set time after you start the machine, it’ll log a fault code. It might even slow the engine down eventually—even if the tank’s full of good DEF.

- Hot weather: Extreme heat is just as bad, if not worse. DEF starts to break down if it’s stored above 86°F (30°C). The urea slowly turns into ammonia, which makes the fluid less effective. Over time, it can even damage the quality sensor. On a super hot job site, the fluid in the tank can hit these temps easily. That shortens the DEF’s life and puts extra stress on the header’s parts.

What Causes DEF Head Failure?

A bad DEF header is one of the most common causes of SCR system error codes on heavy equipment. It’s a complex part, so there are a few different things that can make it fail. Now that we know how it works, let’s go over the most common issues.

Contamination

Dust and dirt are everywhere on job sites. If any gunk gets into the DEF tank when you refill it, it can clog the small filter inside the header. Even worse, tiny particles can get past the filter, damage the delicate quality sensor, or clog up the exhaust injector down the line.

Coolant Leaks

The coolant lines inside the header (they warm up the DEF) can develop tiny cracks over time, from all the machine’s vibration and temperature changes. When that happens, engine coolant (glycol) leaks into the DEF. The DEF quality sensor picks this up right away, triggers an error code, and shuts the system down. If your DEF looks cloudy or oily, a coolant leak is almost always the reason.

Crystallization

When DEF is exposed to air, the water in it evaporates and leaves behind white urea crystals. This can happen around the tank cap, but also inside the header if the system doesn’t purge properly. These crystals build up, clog the suction filter, or mess with the level and quality sensors—causing wrong readings and system failure.

Sensor Malfunction

Sometimes the electronic parts just stop working. The DEF quality sensor is super sensitive. On some older models, ammonia gas (which forms naturally from urea) can slowly seep into the sensor’s housing and corrode the circuit board inside. That makes the sensor stop sending signals to the ECU, and an error pops up right away. Newer headers have better seals to prevent this, but electronics can still fail at any time.

Wrong Urea Concentration

Using low-quality DEF, or fluid that’s broken down from sitting too long or getting too hot, makes the quality sensor read the wrong urea level (it should be 31-33%). This isn’t the header’s fault itself, but the header will send a problem alert to the ECU, and that triggers warnings and engine speed limits.

How Do You Know If DEF Is Bad?

DEF fluid quality is super important for the DEF header to work right, so it’s key to know how to spot bad DEF. The good news is you can usually tell just by looking at it.

Pro tip: Always pour DEF from a sealed container into a clean pitcher or funnel. Never use containers that held other fluids—especially diesel, oil or coolant. Even a tiny bit can cause thousands in damage.

- Check the look: Good DEF is totally clear, just like water. If it’s cloudy, yellowish, or has any little bits floating in it, it’s contaminated or old. Don’t use it.

- Watch for crystals: If you see white crystals in the container or around the opening, the DEF was exposed to air and has started to go bad. Toss it out for the best.

- How to store it: DEF lasts about 1 to 2 years, depending on how warm it’s stored. Keep it in a sealed, non-transparent container, away from direct sun. Don’t store it in carbon steel, copper or zinc-coated steel containers—DEF will corrode these metals and get contaminated with rust. High-density polyethylene (HDPE) or stainless steel containers are the safe choice.

How Often to Change or Add DEF?

Top off the DEF tank whenever it’s low. And it’s a good idea to use up or drain the old DEF every 6–12 months to keep it fresh, especially if the machine sits unused for long stretches.

Your excavator will give you plenty of warnings before you run out of DEF—this system’s made to be impossible to miss:

- 10% full: A solid amber warning light pops up on the dash. No effect on how the machine runs at this point.

- 5% full: The amber light starts flashing, telling you to refill soon.

- 2.5% full: The flashing amber light is joined by a solid red stop light. The ECU will then slow the engine down a lot—usually cutting power by 25–50%—to make you refill the tank.

- Empty: Once the tank’s out of DEF, the engine gets limited even more, often down to just idle speed. The machine won’t work until you refill it.

Refilling is easy. The DEF tank’s almost always right next to the diesel tank, with a bright blue cap so you don’t mix them up. Always wipe the area around the cap clean before opening it, so dirt doesn’t fall in.

Wrapping Up

The DEF header is a complex, precision part, and it’s critical for modern heavy equipment to run clean and efficiently. When your machine needs repairs, you can find all the parts you need in FridayParts’ online shop. Our parts are guaranteed to fit, and we ship fast. Get your machine back up and running in no time.