Do you have a problem in finding the right PTO shaft cause it has so many series? Then you come to the right place. This guide will help you understand what is PTO series is and what they stand for, ensuring you can find the perfect fit for your work.

What is a PTO Shaft Series?

A PTO shaft series is a standardized measurement system that defines how much power a shaft can safely handle. The “series” number refers to the size of the universal joints (U‑joints) — those cross‑shaped parts that allow the shaft to flex and transfer power at an angle.

In short:

A larger series number = a larger and stronger U‑joint, capable of handling more horsepower and torque.

For example, a Series 6 PTO shaft uses a bigger U‑joint than a Series 4, meaning it’s built for more powerful equipment.

Using the wrong series can lead to shaft failure, possible equipment damage, and serious safety risks.

PTO Shaft Series Chart

Here’s an easy‑reference PTO Shaft Series Chart based on common North American standards (Weasler). Use it to identify or compare shaft types.

| PTO Series | Typical HP Rating (at 540 RPM) | U‑Joint Measurement (Cap Diameter × Cross Width) | Common Applications |

|---|---|---|---|

| 1 | 16 HP | 22mm × 54mm (0.87″ × 2.13″) | Small tillers, log splitters, generators |

| 2 | 20 HP | 23.8mm × 61.3mm (0.94″ × 2.41″) | Small rotary cutters, post‑hole diggers |

| 3 | 30 HP | 27mm × 70mm (1.06″ × 2.76″) | Mid‑size tillers, small round balers |

| 4 | 35 HP | 27mm × 74.6mm (1.06″ × 2.94″) | Most rotary cutters, hay rakes, and standard balers |

| 5 | 47 HP | 30.2mm × 80mm (1.19″ × 3.15″) | Mid‑size square balers, feed mixers |

| 6 | 62 HP | 30.2mm × 92mm (1.19″ × 3.62″) | Round balers, wood chippers, and large rotary cutters |

| 7 | 77 HP | 35mm × 94mm (1.38″ × 3.70″) | Large feed mixers, forage harvesters |

| 8 | 95 HP | 35mm × 106.5mm (1.38″ × 4.19″) | Large forage harvesters, large square balers |

How to Choose the Right PTO Shaft: A 4‑Step Guide

Now that you understand the meaning of PTO series numbers, follow these four steps to find exactly what you need.

First Step: Determine Your Required PTO Series

This is the most important step. If you’re unsure, “how do you know what series PTO shaft you have?”, use one of these proven methods:

1. Check Your Implementation’s Manual

Your equipment’s manual is the best and most accurate source — it clearly lists the required PTO series and horsepower rating.

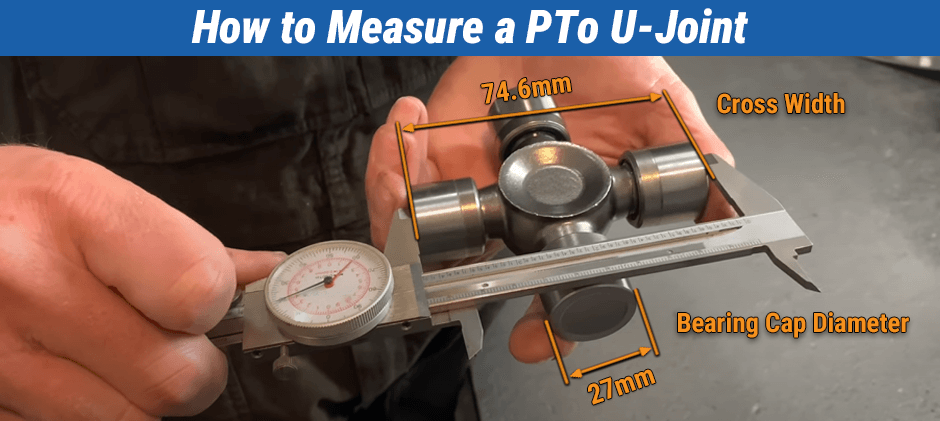

2. Measure Your Existing U‑Joint

If you have the old shaft, measure the U‑joint to identify its series — you’ll need a caliper for accuracy.

- Measure the Cap Diameter: the outside of one of the four bearing caps.

- Measure the Cross Width: distance across the U‑joint from end to end.

Compare your two measurements to the PTO Shaft Series Chart above to confirm your series.

3. Estimate Based on Horsepower

If you don’t have a manual or an old shaft, use your tractor’s PTO horsepower as a reference.

Always select a PTO shaft rated equal to or greater than your tractor’s PTO power.

Never undersize — when in doubt, size up for safety.

Second Step: Find the Correct Length

PTO shafts are sold by their closed length (fully retracted). You’ll typically need to adjust or cut them to achieve the correct working size.

1. Measure Your Working Length:

With the tractor and implement connected in a straight line, measure from the outside of the tractor’s PTO output groove to the implement’s input shaft groove.

2. Check Extreme Lengths:

With the implement raised and lowered, measure at both extremes to ensure the shaft won’t be too long or too short.

3. Cut to Size Correctly:

When trimming a new shaft, maintain:

- At least 1/3 overlap at full extension.

- At least a 1‑inch clearance before full compression.

- Please cut both the inner and outer tubes equally, and shorten the plastic safety shields to match.

Third Step: Match the Tractor and Implement Connections (Yokes)

You’ll need to match the PTO connections at both ends — one for your tractor, one for your implement.

Tractor End:

- Standard 540 RPM PTOs usually use a 1‑3/8″ 6‑spline shaft.

- Typical 1000 RPM systems feature a 1‑3/8″ 21‑spline connection.

- High‑horsepower 1000 RPM applications rely on a 1‑3/4″ 20‑spline interface.

Implement End:

Implements may have a similar splined connection or a built‑in safety device, such as:

- Shear Bolt: Breaks under overload to protect gears.

- Slip Clutch: Uses friction plates that slip on impact — ideal for rotary tillers that may hit rocks.

- Ratchet Clutch: Transfers power in one direction only — common on large mowers and balers.

Fourth Step: Don’t Forget the Safety Features

A complete PTO shaft assembly includes more than metal tubing. It must also have:

- A Fully Intact Safety Shield: The plastic cone and tube covering the shaft — never operate without it.

- Safety Chains: These secure the shield to both the tractor and the implement, keeping it still while the shaft rotates.

Remember: a spinning shield is nearly as dangerous as an exposed shaft.

Your PTO Shaft Selection Checklist

Before buying, review this quick list:

- PTO Series: (e.g., Series 6)

- Length: (Closed length slightly shorter than minimum working length)

- Connections: (Match tractor end and implement end)

- Safety: (Complete shield and intact safety chains)

Protect Your Investment and Your Safety

Understanding what PTO is on a tractor and how to properly connect it is essential for safe, efficient operation.

By correctly identifying your PTO series, length, and connection types, you ensure:

- Better power transfer

- Less equipment wear

- A much safer work environment

Now that you know exactly what to look for, you can confidently choose high‑quality PTO shafts and PTO shaft parts at FridayParts to keep your tractor and implements performing their best — year after year.