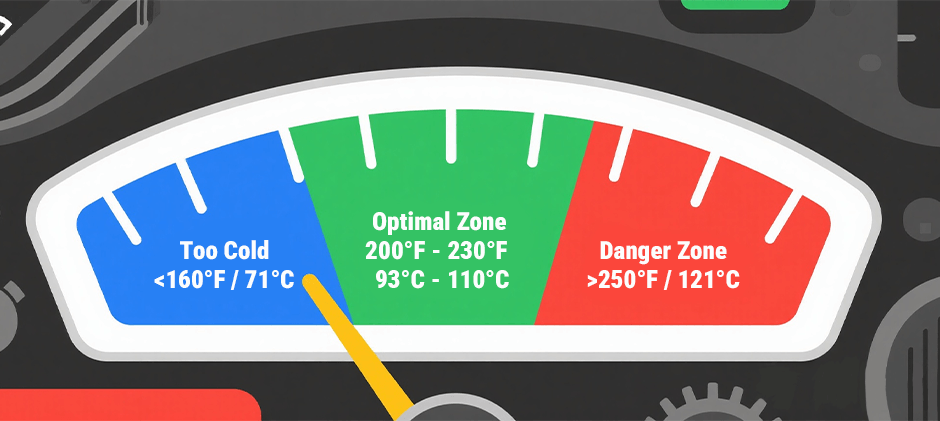

What Is Normal Oil Temp? For most off-road diesel machines, a normal engine oil temperature is usually 200°F to 230°F (93°C to 110°C) after the engine is fully warmed up. If you often see 250°F+ under load, you are getting into a risky zone. Keeping oil temperature in the safe range helps your excavator, loader, or tractor run smoothly and protects expensive engine parts.

What Is the Normal Oil Temp for Diesel Machinery?

Heavy equipment diesel engines usually run at steady, moderate oil temperatures once warmed up.

- A good “happy” number for many machines is around 210°F (99°C).

- When you work hard (digging, pushing, climbing, running hydraulics), oil temp may rise—but it should level off after a while.

- If your gauge stays above 240°F, the oil can start to break down faster and protect the engine less.

Clear Statement: “Your equipment runs on diesel, but it lives on oil. Keep it in the safe zone.”

What Happens When Oil Gets Too Hot?

When oil gets too hot, it cannot protect the engine as well.

- At very high temperatures, oil gets too thin.

- Thin oil makes it easier for engine parts to touch each other, which causes wear.

- Heat also makes oil age faster, and old oil can turn into sludge that blocks small oil passages.

Signs of Overheating Oil

- Oil pressure drops (hot, thin oil).

- Knocking or ticking sounds from the engine.

- A burnt/hot smell when you check the dipstick area.

Simple rule: “Hot oil = weaker protection.”

Can Engine Oil Be Too Cold?

Yes. Oil that stays too cold can also hurt your engine.

- If oil is below about 160°F (71°C), it can be thick and slow.

- Thick oil does not flow fast, so it may not reach important parts quickly (like the turbo and the valvetrain).

- If the engine never gets warm enough, water from condensation may stay in the crankcase instead of burning off.

Pro Tip: “Never put a machine under full load until the oil temperature gauge moves off the bottom peg. Warm-up time is not wasted time.”

Simple rule: “Cold oil flows slow. Give it time.”

How Do Oil Coolers Regulate Temperature?

Most heavy machines use an oil cooler to keep the oil temperature steady.

An oil cooler is like a small radiator for oil. It moves heat out of the oil and into:

- the engine coolant, or

- the air (depending on the design)

Off-road machines often work hard at low travel speeds, so they do not get much natural airflow. In dusty places, the cooler fins can plug with dust, chaff, or mud. When airflow is blocked, oil temp can climb.

Simple rule: “If the cooler stack is dirty, heat can’t escape.”

4 Ways to Maintain Optimal Oil Temperature

Most oil temperature problems can be reduced with basic checks.

1. Clean the Radiator and Cooler Stack

Dirt blocks airflow like a blanket. Clean out the cooling package often (follow safe cleaning steps for your machine).

2. Check Oil Levels Daily

Low oil heats up faster. Less oil also means less oil to carry heat away. Make sure you know how to read the engine oil dipstick correctly.

3. Use the Correct Viscosity

Use the oil grade listed in the OEM manual. Wrong viscosity can change oil flow and heat control, especially in cold or hot weather.

4. Monitor the Gauge Under Load

Check oil temp while doing the hardest work, not just at idle. That is when problems show up.

Simple rule: “Clean cooling + correct oil + correct level = stable temp.”

When Should You Change the Oil?

Heavy equipment oil changes are usually based on engine hours, not miles.

- Many machines fall in the 250–500-hour oil change range (always follow the manual for your engine).

- If the engine overheats badly, it is smart to change the oil sooner, because extreme heat can damage the oil and its additives—even if the oil still looks clean. You should also check if you need to replace the engine oil filter at the same time.

Simple rule: “Hours matter more than miles.”

Conclusion

Keeping a normal oil temperature—often around 210°F, and generally 200°F to 230°F once warmed up—helps your diesel engine last longer. Clean your cooler stack, keep the oil level correct, use the right oil, and warm up before heavy work. Oil is the engine’s protection layer; when oil fails, engine wear speeds up fast.

If overheating keeps happening even after basic checks, inspect cooling parts (cooler stack, fan, hoses, thermostat, sensors) and repair what’s weak so you can trust the readings and keep temperatures under control.