An air compressor aftercooler is a device that cools the hot, compressed air coming from a compressor to reduce its temperature and moisture. The air compressor is the heart of the pneumatic tool system. The air coming out of the compressor is very hot and contains a lot of water vapor. High heat and harmful moisture usually cause silent damage to your equipment. Aftercoolers are the solution to these problems for your equipment.

If you are curious or confused about its principles and functions, then after reading this guide, you will fully understand what an air compressor aftercooler is, how it works, what different types there are, and its importance to help you fully understand this important component.

What is an Air Compressor Aftercooler?

At its core, an air compressor aftercooler is a type of heat exchanger. Its primary job is to cool the hot air that comes directly out of your air compressor. When air is compressed, the molecules are forced closer together, which generates a tremendous amount of heat. This heat can raise the temperature of the fuel injection system to 200°F. These extreme temperatures can retain more water and cause serious damage to the equipment’s air lines.

A fundamental principle of physics is that hot air can hold a lot more water vapor than cold air. The air your compressor draws in from the atmosphere is already filled with moisture, especially on humid days. When that air is compressed and heated, it becomes a supersaturated, hot, wet gas.

An air compressor aftercooler tackles both of these problems at once. By cooling the air, it forces the suspended water vapor to condense into liquid water, which can then be easily removed from the system.

How the Aftercooler Works and Its Function

The process inside an air compressor aftercooler is simple yet highly effective. It acts as the first and most critical step in air treatment, immediately after the air leaves the compressor pump.

Here’s a breakdown of its function:

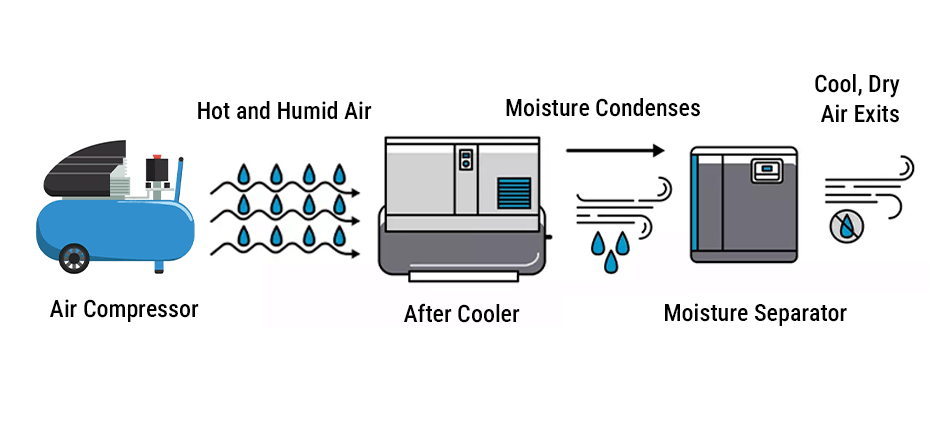

- Hot Air Enters: The moment hot, moisture-laden compressed air exits the compressor, it is channeled directly into the aftercooler.

- Heat Exchange Occurs: The air travels through a network of tubes or fins. A cooling medium—either ambient air or water—is passed over these surfaces. This action pulls the heat away from the compressed air, causing its temperature to drop rapidly.

- Moisture Condenses: As the air cools, it quickly reaches its “dew point,” the temperature at which it can no longer hold its water vapor. This vapor transforms into liquid water droplets. An efficient aftercooler can remove up to 75% of the moisture from the compressed air.

- Separation and Drainage: The mixture of cooled air and liquid water then typically flows into an integrated moisture separator. Here, the heavier water droplets are collected at the bottom and are purged from the system through a drain valve, which can be automatic or manual.

- Cool, Dry Air Exits: The resulting air that leaves the aftercooler is significantly cooler and drier, ready to be used by your tools or sent to a secondary air dryer for further purification if needed.

Think of an aftercooler as the heavy-lifter in your air treatment system. It does the bulk of the hard work, making every other component downstream more effective and last longer. Without an aftercooler, this hot, wet air flows directly to your tools and equipment, leading to a host of problems.

Air-Cooled vs Water-Cooled Air Compressor Aftercoolers

Air compressors’ aftercoolers generally fall into two categories: air-cooled and water-cooled. While their goal is the same—to reduce the temperature of compressed air and remove moisture—their cooling methods and applications differ. For off-road and mobile equipment, one type is far more common than the other.

Air-Cooled Aftercoolers

This is the most common type found on off-road equipment compressors. Air-cooled models rely on airflow to carry heat away from the compressed air. As the hot air travels through a series of coiled tubes or finned surfaces, cooler ambient air is pushed across the coils, often using a fan. This process brings down the temperature of the air to just above the ambient air temperature, typically within 15 to 20 degrees Fahrenheit.

As the air cools, water vapor naturally condenses into liquid. A built-in moisture separator, often using spinning or baffled mechanisms, collects this moisture and removes it via an automatic drain. Some compact compressors even integrate the aftercooler into the belt guard, where rotating pulleys help direct airflow across the heat exchange surface.

Water-Cooled Aftercoolers

Water-cooled systems use circulating water as the cooling agent. These are more common in large or fixed industrial setups where a continuous supply of cold water is available. Because water holds temperature more consistently than air, this type of cooler can achieve a tighter temperature drop—sometimes within 10 to 15 degrees of the water temperature—making it especially effective in demanding environments.

The most typical design is a shell-and-tube configuration, where compressed air flows through internal tubes while water passes over them in the opposite direction. The heat from the air transfers into the water, reducing air temperature and allowing moisture to condense, which is then removed similarly through a drainage system.

Which Air Compressor Cooler is Right for You?

For owners of off-road machinery, the choice is almost always clear. Your equipment operates in varied, often remote environments without access to plumbing. Therefore, the air-cooled air compressor aftercooler is the standard and most practical solution.

For off-road machinery owners, air-cooled aftercoolers are typically the best choice. They’re easier to install, don’t require plumbing, and work well in remote or dusty environments. Maintenance is minimal—just occasional cleaning of fins and fans. While their cooling efficiency depends on ambient temperature, they’re ideal for small to mid-sized machines.

Water-cooled aftercoolers, on the other hand, offer more consistent cooling in extreme heat but need a stable water supply, complex installation, and higher upkeep. They’re better suited for large, stationary equipment and come with a higher upfront cost.

Why Your Equipment Needs to Dry Compressed Air?

Neglecting to use an aftercooler on your heavy equipment isn’t just inefficient; it’s a recipe for costly failures and downtime. If there is no dry compressor air, the following practical consequences will occur:

- Destruction of Pneumatic Tools: This is the most direct impact. Moisture causes internal rust and corrosion, washing away lubrication and destroying delicate components inside impact wrenches, grinders, and drills.

- Failure in Critical Applications: For certain jobs, wet air is an absolute deal-breaker.

- Painting/Coating: Moisture will cause defects like “fisheyes” and blistering, ruining the finish.

- Sandblasting: Damp abrasive media will clump together, clogging the nozzle and leading to an uneven, ineffective blast.

- Winter Operations Failure: In cold weather, the moisture in your air lines can freeze solid, completely blocking airflow and potentially cracking hoses or tool housings.

- Safety Hazards on the Job Site: Hoses carrying air at over 200°F pose a serious burn risk to operators. An aftercooler brings the air temperature down to a much safer level, typically within 10-20°F of the ambient temperature.

The Benefits of Having an Aftercooler for Your Air Compressor

Installing a high-quality air compressor aftercooler is a proactive measure that delivers tangible returns. The benefits are clear and directly impact your bottom line and operational readiness.

- Extends Tool and Equipment Lifespan: By delivering cool, dry air, you drastically reduce the main cause of pneumatic tool failure—internal corrosion. Your tools last longer and require fewer repairs.

- Improves Work Quality and Consistency: You can trust your equipment to perform correctly every time.

- Lowers Overall Operating Costs: You save money in multiple ways: fewer tool replacements, reduced maintenance on air dryers, and less wasted material from failed applications.

- Enhances Job Site Safety: Reducing the temperature of compressed air hoses minimizes the risk of burns, contributing to a safer work environment for everyone.

In the operation of the air compressor, the role of the aftercooler cannot be ignored. Using high-quality and professional aftercoolers can not only ensure the efficiency of the equipment but also save maintenance costs. Choose a high-quality parts supplier and let these experts with many years of experience in the parts field, such as FridayParts, protect your equipment.

Conclusion

The air compressor aftercooler is not a luxury item; it is a fundamental component for any serious operator of off-road machinery. It serves as the first line of defense, protecting your valuable pneumatic tools from the damaging effects of heat and moisture. By cooling the air and removing the bulk of its water content, it ensures your entire system operates reliably, efficiently, and safely. This simple device saves you money, prevents downtime, and guarantees the quality of your work.

At FridayParts, we understand that the reliability of your equipment is crucial to your livelihood. If you need to replace a faulty aftercooler or add one to your system, we are here to help. We specialize in providing high-quality aftermarket parts at affordable prices, with a vast inventory compatible with leading heavy equipment brands like Caterpillar, Komatsu, Kubota, and more. Don’t let hot, wet air compromise your work. Explore our range of aftercoolers to find the right part for your machine and benefit from our fast, global shipping.