What is a sprocket? On heavy equipment, sprockets transfer power from the engine or hydraulic system to the tracks. They lock perfectly with the track links, turning rotational power into forward, reverse and steering movement for the machine. Plus, they take on high torque and heavy impact forces—they’re a must-have, critical part of the track drive system.

What is a Sprocket?

A sprocket is a toothed wheel that connects with a chain. It looks like a gear, but they work differently. Gears mesh with other gears, sprockets only work with chains. For excavators, dozers and other off-road machines, we mostly talk about the drive sprocket.

It’s no ordinary toothed wheel. The drive sprocket is the last part of the machine’s power system. It takes spinning force from the final drive motor and sends it straight to the track chain. Think of it as the bridge between the engine’s power and the ground. It turns the hydraulic motor’s spin into forward movement, moving your heavy machine across the job site. If the sprocket doesn’t work properly, all the engine’s power is completely wasted.

How Does a Sprocket Work?

A sprocket works because of positive engagement. A car tire uses friction to move, but a sprocket locks directly with the chain mechanically. It transfers power powerfully without slipping—this is vital for moving heavy loads on rough ground. Here’s how it works step by step:

- Power input: The excavator’s hydraulic final drive motor spins a shaft, and the drive sprocket is attached to this shaft.

- Engagement: As the sprocket turns, each tooth fits perfectly into a gap on the track chain. This gap is made by the track’s bushings. The tooth doesn’t just push the chain; it wraps around the bushing to form a tight connection.

- Linear motion: This tight, synchronized connection pulls the whole track chain forward, making the machine move. Each tooth locks and unlocks smoothly with each bushing as the sprocket spins.

One measurement is crucial for this system to work: pitch. Pitch is the distance from the center of one sprocket tooth to the next. This distance must match the track chain’s pitch exactly—that’s the distance from the center of one bushing to the next.

Sprocket and chain must have a perfectly matching pitch. Even a small mismatch from wear will speed up damage to both parts a lot, and cause expensive downtime. If the pitch is wrong, the chain rollers will climb the sprocket teeth instead of fitting properly. This causes shaking, loud noise, and severe wear on both the sprocket teeth and chain bushings.

Types of Sprockets & Applications

All heavy equipment sprockets do the same basic job, but they come in different designs and materials. Each type is made for specific machines and work needs.

Segment vs. One-Piece

- One-Piece Sprockets: Used on smaller excavators and machines. It’s a single solid piece, cast or forged, bolted to the final drive. To replace it, you have to take off the entire track first.

- Segment-Type Sprockets: Found on most mid and large excavators, plus dozers. It’s made of 3 to 5 separate sections that bolt on. This design is way better for maintenance. When the sprocket wears out, just unbolt the old sections and put on new ones—no need to take the track apart. Saves a ton of time and work on the job site.

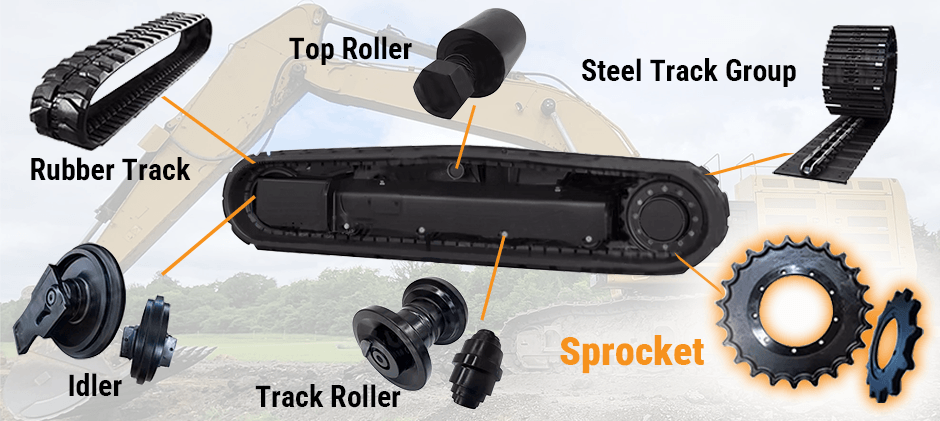

Drive Sprocket vs. Idler

- Drive Sprocket: This is the powered toothed wheel we’ve talked about. It’s usually at the back of an excavator’s undercarriage, and it actively pulls the track chain.

- Idler: It’s the big wheel at the front of the undercarriage, with the track chain running over it. It might have a simple tooth-like shape, but it has no power. Its main jobs are guiding the track chain and keeping the right track tension with an adjuster. It just guides the track—doesn’t drive it.

By Material and Hardness

Sprockets work in super harsh conditions, grinding against dirt, sand and rock nonstop. So the material and how it’s made are really important. They’re almost always made from high-strength steel alloys and go through special heat treatment like induction hardening. This makes the outer surface of the teeth ultra-hard to resist wear, while the inner part stays a bit softer. The soft core soaks up shock without cracking. A cheap sprocket with bad hardening will wear out in a tiny fraction of the time a quality one does.

Which Gear for Which Torque?

Torque is the rotational force—aka the pulling power—that gets the real work done. A sprocket’s size (mainly its diameter and number of teeth) directly affects this power balance.

Bigger Sprocket (More Teeth): A larger sprocket with more teeth gives a mechanical boost that means higher torque. At any time, more teeth lock into the track chain, spreading the load over a bigger area. This creates a strong, steady pull—perfect for heavy digging, climbing steep hills, or pushing huge loads. The catch? The top travel speed is slower. For most earth-moving jobs, high torque is what matters most.

Smaller Sprocket (Fewer Teeth): Same motor speed, a smaller sprocket spins the tracks faster – so the machine’s top speed is higher. But it means less torque. Faster travel between work spots on a big, flat job site sounds nice, but the machine won’t have enough power for real work like digging and pushing. For off-road machines such as excavators, designers almost always choose a sprocket size that boosts torque to the max. This way, the machine has all the raw power it needs to do its main jobs properly.

How to Extend the Life of Your Sprockets?

Sprockets are wear parts—they won’t last forever. But with proper use and regular maintenance, you can make them, and the whole undercarriage, last a lot longer.

Keep the Undercarriage Clean

Mud, gravel and dirt get stuck between sprocket teeth and chain bushings, making a grinding paste of sorts. It also stops the chain from fitting properly, which adds way more load to the teeth and wears them out faster. Get into the habit of cleaning the undercarriage at the end of every workday.

Keep Track Tension Just Right

This is probably the most important thing for the undercarriage’s lifespan.If the track’s too tight, it puts huge stress on the sprocket, bushings, idlers and final drive bearings. It’s like driving a car with the parking brake on a little—everything wears out quicker.If the track’s too loose, it’ll slap around, and the sprocket teeth might even jump out of the bushings. This can badly damage both parts. Check your operator’s manual for how to measure and adjust track sag the right way.

Operate the Machine Carefully

How you use the machine directly affects sprocket wear. Don’t drive at high speed too much—this means more tooth and chain engagements, and more wear over time. Also, try to avoid sharp pivot turns in one spot (counter-rotation). This puts a massive side load on the undercarriage parts. When you can, make wider, slower turns instead.

Regular Checks Are a Must

Look at your sprockets often. A new sprocket has thick, rounded teeth. As it wears, the teeth get thinner, sharper and hooked—eventually looking like shark fins. Once you see this sharp, pointed shape, the sprocket’s worn out and needs replacing. If you have a segmented sprocket, also check for any loose bolts.

Replace Parts As a Set

Never replace just the sprocket without the track chain, or just the chain without the sprocket. Putting a new sprocket on a worn, stretched chain will wear the new sprocket out super fast. And a new chain on worn shark-fin sprockets will quickly ruin the new chain’s bushings. For the best results and lowest long-term cost, always replace sprockets and chains as a matched set.

In Conclusion

Sprockets power the chain drive systems that move heavy loads. Picking the right sprocket keeps the system running smoothly and stops your equipment from getting damaged or worn out fast. To get it right, you need to know the exact specs of the sprocket and chain for your system, plus the right mounting type. If you spot any signs of wear or damage, replace the sprocket right away. FridayParts works with all major heavy equipment brands. We help you get the perfect replacement parts quickly, so you can get back to work fast without going over budget.