A blower motor is an electric motor that heats, cools, and circulates air by driving a fan or blower. It ensures air circulation in the cockpit and provides a comfortable operating environment for the driver. The blower motor might be small, but it plays a big role in keeping your machine—and you—comfortable. Whether you are in winter or summer, the blower motor is heating and cooling your cab and always providing you with fresh air.

In this article, we will introduce the function, working principle, classification, and application scenarios of the blower motor in detail. Finally, we also prepared some basic blower motor maintenance tips and problem answers for you to help you fully understand this key component.

What is a Blower Motor, and What Does it Do?

In simple terms, the blower motor is the electric motor that powers the main fan inside your machine’s HVAC (Heating, Ventilation, and Air Conditioning) unit. It is the heart of the climate control system, responsible for pushing air through the vents and into the cab.

Its function is vital for several key operations:

- Heating: It forces air across the heater core to warm the cabin.

- Air Conditioning: It blows air over the A/C evaporator to provide cool air.

- Ventilation: It circulates air to keep the cab environment fresh.

- Defrosting: It directs a strong flow of air onto the windshield to clear away fog and frost, a critical safety function.

It is important to distinguish the cab’s blower motor from the engine’s cooling fan motor. The latter is a much larger fan located near the radiator, and its job is to cool the engine itself, not the operator. The blower motor is entirely dedicated to the climate inside the cab.

How Does the Blower Motor Work?

The operation of the blower motor is a straightforward process. When you adjust the fan speed on your control panel, a simple chain of events occurs:

- Your command sends an electrical signal through the system.

- This signal activates the blower motor, which is typically a 12-volt or 24-volt DC motor.

- The motor begins to spin rapidly. Attached to its shaft is a round, cage-like fan, often called a “squirrel cage” or blower wheel.

- The spinning fan pulls air into the HVAC housing and then forcefully pushes it through a series of ducts.

- Depending on your selection, this air is directed over the hot heater core or the cold A/C evaporator.

- Finally, the conditioned air flows out of the vents and into your cab at the speed you selected.

In short, the blower motor turns your fan speed setting into real airflow—powering comfort by pushing heated or cooled air exactly where you need it.

Key Components of Blower Motors

The blower motor is more than just a motor; it’s part of an assembly with several key components working together.

- Electric Motor: This is the core component, a small but powerful DC motor designed for thousands of hours of operation.

- Blower Wheel (Fan): This is the plastic “squirrel cage” fan that attaches to the motor’s shaft. Its design is highly efficient at moving large volumes of air.

- Housing: This is the plastic or metal casing that encloses the motor and fan, protecting them and directing the airflow.

- Blower Motor Resistor or Control Module: This crucial electronic component controls the fan’s speed. A resistor uses different electrical pathways to slow the current and thus the motor’s speed for lower settings. A control module does this electronically for variable-speed systems.

Different Types of Blower Motors

While commonly referred to as a “blower motor,” the actual fan design varies across a few engineering types—each with its own airflow and pressure characteristics. In heavy equipment HVAC systems, one type is overwhelmingly dominant.

1. Centrifugal (Radial) Blower

This is the most common type in heavy equipment. The familiar “squirrel cage” fan is a centrifugal blower, which works by spinning a fan (impeller) that throws air outward using centrifugal force. This increases air speed and pressure, making it effective at pushing air through ducts, filters, and heat exchangers.

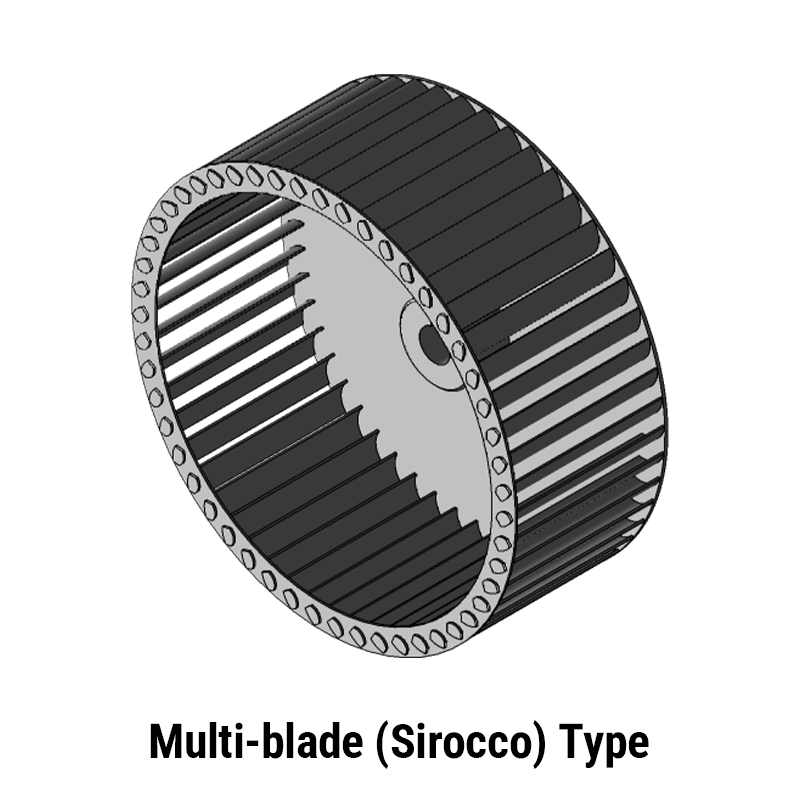

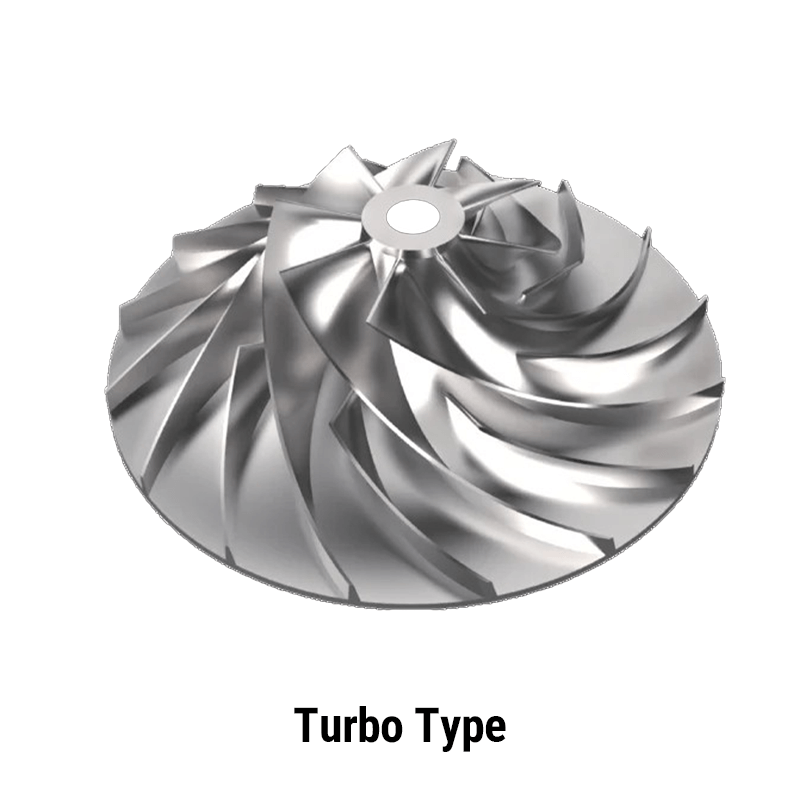

Two subtypes exist:

2. Axial Flow Blower

Resembling a propeller, an axial blower pushes air parallel to its shaft. It’s efficient at moving large volumes of air in open spaces, but can’t generate much pressure and tends to be noisy. While not used for cab HVAC, small axial fans may cool control modules or hydraulic oil systems.

3. Cross Flow & Diagonal Flow Blowers

Less common in heavy equipment:

- Cross Flow: Cylindrical fans that move air evenly across their length. Quiet, but not suited for pressurized systems.

- Diagonal Flow: A hybrid design that combines axial intake with diagonal output, balancing flow and pressure.

Although there are several designs, the most commonly used replacement blower motor in off-road equipment is the centrifugal (Sirocco type) blower motor.

Signs of Blower Motor Might Need Attention

A failing blower motor rarely dies without warning. Learning to spot these signs can help you diagnose the problem before you’re left without air.

- The Fan Only Works on the “High” Setting: This is the most common symptom of all. If your fan is dead on the lower speeds but works perfectly on high, the blower motor itself is fine. The problem is a failed blower motor resistor. The high setting is wired to bypass the resistor, which is why it’s the only one that works.

- Weak or No Airflow: If the airflow from your vents is noticeably weaker than it used to be on all settings, it could be a sign of a dying motor or a severely clogged cabin air filter. If there is no airflow at all, the motor has likely seized, or there’s an electrical issue like a blown fuse.

- Unusual Noises: Your ears are an excellent diagnostic tool.

- A high-pitched squeal or screeching that changes with fan speed indicates the motor’s internal bearings are worn out and failing.

- A rattling or clicking sound often means debris, like a leaf or piece of plastic, has been sucked into the fan cage.

- A low, persistent humming can signal an electrical problem or a motor that is struggling to turn.

- A Burning Smell: This is a serious safety warning. If you smell burning plastic or an electrical odor coming from your vents, the motor is likely overheating. Shut the system off immediately to prevent a potential fire.

Basic Maintenance Tips for Blower Motors

You can significantly extend the life of your blower motor with a few simple maintenance steps:

- Replace the Cabin Air Filter Regularly: This is the single most important thing you can do. A clean filter allows for easy airflow, reducing strain on the motor. Check it every few months and replace it at least once a year, or more often in very dusty conditions.

- Keep the Air Intake Area Clean: Regularly clear leaves, dirt, and other debris from the cowl area at the base of the windshield where the HVAC system draws in fresh air.

- Listen for Problems: Don’t ignore strange noises. A squealing motor is a motor that’s about to fail. Addressing it early can prevent you from being stranded without a fan.

Regular maintenance, like changing filters and keeping the intake clean, goes a long way in keeping your blower motor running smoothly and avoiding bigger issues down the road.

FAQs About Blower Motors

Q: Why does my fan only work on the highest speed?

A: This is the classic sign of a failed blower motor resistor. The resistor controls the lower speeds, and the high-speed setting is wired to bypass it. Replacing the resistor, not the motor, will fix this problem.

Q: Can I just clean a noisy blower motor instead of replacing it?

A: If the noise is a rattle, it’s likely caused by debris that can be cleaned out. However, if the noise is a high-pitched squeal, the internal bearings are worn out, and the entire motor assembly needs to be replaced.

Q: Is a failing blower motor dangerous?

A: It can be. A motor that produces a burning smell is a fire hazard and should be shut off immediately. Furthermore, a non-functioning motor means you cannot defrost your windshield, which is a serious safety issue in cold or humid weather.

Conclusion

The blower motor is a small but mighty component in the complex ecosystem of your heavy machinery. It is the key to operator comfort, focus, and safety in all weather conditions. By understanding how it works and learning to recognize the common signs of failure, you can perform quick diagnostics and prevent a minor annoyance from becoming a major problem. A proactive approach to maintenance and replacement ensures your cab remains a productive and safe workspace, no matter the conditions outside.

If you’ve identified a failing blower motor or resistor in your equipment, FridayParts has the high-quality, affordable replacement you need. We carry a vast inventory of parts for top heavy equipment brands like Caterpillar, Komatsu, John Deere, and more. Don’t sweat through another shift or shiver through a cold morning. Find the right part at FridayParts and get your climate control system running like new.