If you’ve ever rebuilt a high-performance diesel or dealt with repeated head gasket failures, you’ve probably heard someone mention fire rings. But what exactly are these mysterious metal rings, and why do some diesel engines absolutely need them while others run fine without them? At FridayParts, we’ve supplied thousands of head gaskets and fire ring kits over our 16 years, and we’ve seen firsthand how the right sealing solution can make or break an engine build. Let’s demystify fire rings and help you understand when they’re necessary, how they work, and whether your diesel could benefit from this upgrade.

What are Fire Rings

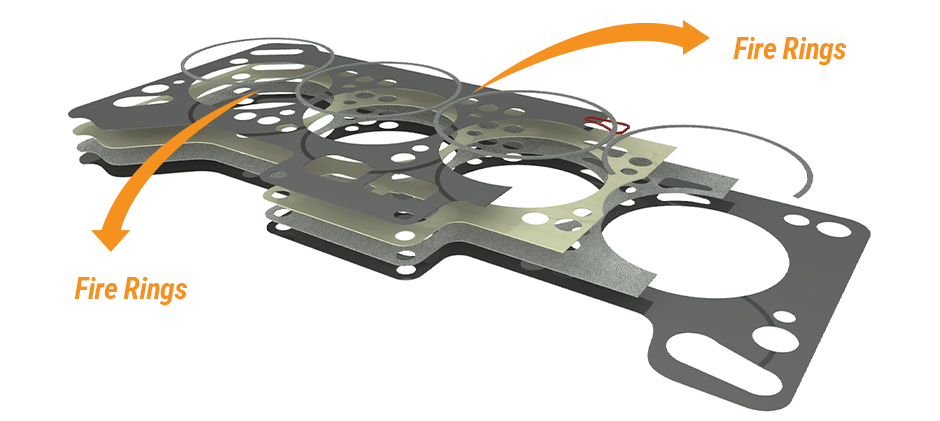

Fire rings are precision-machined metal rings that sit in grooves cut into either the cylinder head or engine block (and sometimes both) around each cylinder bore. Think of them as an extra line of defense for your head gasket, specifically designed to handle the extreme pressures and temperatures that occur right at the combustion chamber. Unlike a standard head gasket that relies on compressed materials to seal, fire rings create a metal-to-metal seal that can withstand incredibly high cylinder pressures.

The primary purpose of fire rings is to contain combustion pressure and prevent it from blowing past the head gasket. In a diesel engine, cylinder pressures can exceed 2,000 PSI during combustion – that’s like stacking three Honda Civics on every square inch of the head gasket. Standard head gaskets, even multi-layer steel (MLS) versions, can struggle with these pressures, especially in modified engines making big power.

What Fire Rings Actually Do:

- Create a positive mechanical seal around each cylinder

- Prevent combustion gases from escaping between the head and the block

- Protect the head gasket from direct exposure to combustion

- Allow for higher boost and cylinder pressures

- Reduce the head lift under extreme loads

- Provide consistent sealing even with minor head/block imperfections

“Fire rings are like putting a steel fortress around your combustion chambers,” explains a diesel performance shop owner. “When you’re pushing serious boost or running compound turbos, that standard head gasket becomes the weak link. Fire rings eliminate that weakness.”

The name “fire ring” comes from their location – they literally ring the fire (combustion) zone of each cylinder. Some people call them gas rings or combustion seal rings, but they all serve the same purpose: keeping the explosion where it belongs.

How Fire Rings Work in Diesel Applications

Understanding how fire rings actually function helps explain why they’re so effective in high-pressure diesel applications. The physics behind fire ring sealing is different from conventional head gaskets, and that difference is what makes them ideal for extreme conditions.

The Sealing Mechanism:

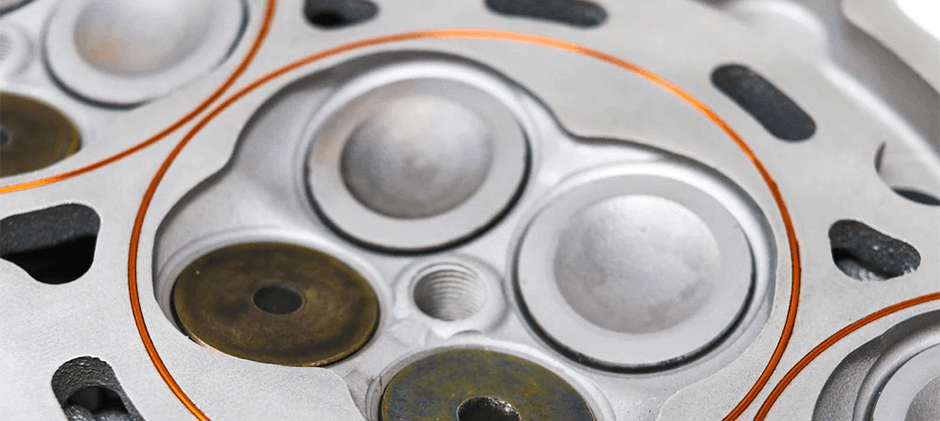

Fire rings work on a principle called “confined compression.” When the cylinder head is torqued down, the fire ring is compressed into its groove, creating tremendous unit loading (pressure per square inch) at the contact points. Because the contact area is so small – just the thin edge of the ring – the sealing pressure is incredibly high, often exceeding 200,000 PSI at the contact line.

Why This Matters in Diesels:

Diesel engines create pressure in two ways:

- Compression pressure: 500-800 PSI, just from the compression stroke

- Combustion pressure: 1,500-2,500+ PSI when fuel ignites

Standard head gaskets must seal against both pressures while also dealing with :

- Thermal expansion and contraction

- Head lift from cylinder pressure

- Vibration and harmonics

- Chemical attack from combustion gases

Fire rings excel here because they:

- Don’t rely on the gasket material crushing

- Maintain the seal even if the head lifts slightly

- Can handle extreme temperatures without degrading

- Create a gas-tight seal at the molecular level

The Complete System:

Fire rings don’t work alone. They’re part of a sealing system that includes:

- Receiver grooves: Machined channels that hold the rings

- Secondary sealing: Regular head gasket for coolant and oil

- Proper surface finish: Both surfaces must be precisely machined

- Correct protrusion: The Ring must stick up the exact amount from the groove

“Think of fire rings like piston rings for your head gasket,” notes an engine machinist. “Just like piston rings seal combustion in the cylinder, fire rings seal it at the deck surface. The physics is similar – metal-to-metal contact under extreme pressure.”

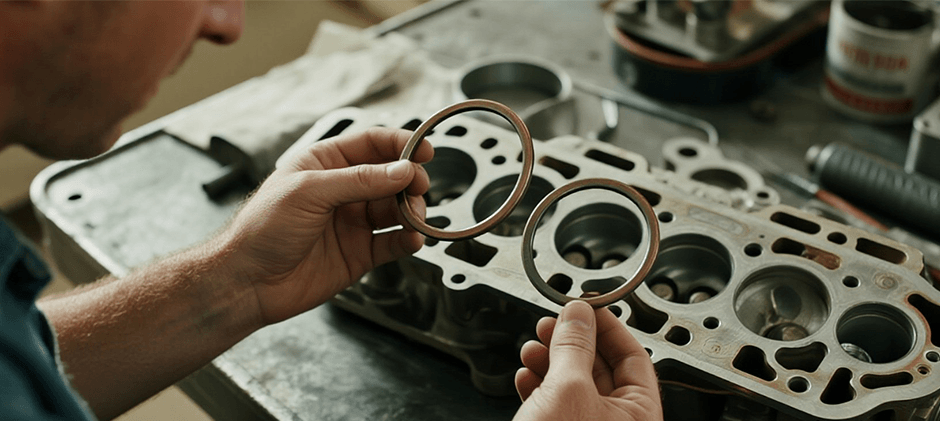

Common Fire Ring Materials and Designs

Not all fire rings are created equal. The material and design of your fire rings can make the difference between a bulletproof seal and a comeback repair. Let’s break down what’s available and what works best for different applications.

Fire Ring Materials:

Stainless Steel:

- The most common material for diesel applications

- Excellent corrosion resistance

- Good spring-back characteristics

- Works well with iron blocks and heads

- Temperature stable to 1,500°F+

- Cost-effective option

Copper:

- Traditional choice for racing applications

- Excellent conformability to surface irregularities

- Requires frequent retouching

- Can work-harden and crack over time

- Better for short-duration racing than daily drivers

Inconel:

- Premium aerospace material

- Extreme temperature resistance (2,000°F+)

- Maintains spring tension at high temps

- Expensive but virtually indestructible

- Used in the most extreme applications

Design Variations:

Wire Ring Style:

- Simple round cross-section

- Easiest to install

- Good for moderate pressure increases

- Most affordable option

D-Ring Profile:

- Flat on one side, curved on the other

- Better gas sealing than round wire

- Reduced receiver groove depth required

- Popular in performance applications

Diamond Profile:

- Sharp edges for maximum sealing pressure

- Requires precise machining

- Ultimate sealing capability

- Most expensive option

Gas-Filled Rings:

- Hollow rings with pressurized gas inside

- Self-energizing under heat and pressure

- Used in extreme racing applications

- Not practical for street use

“Material selection depends on your application,” advises a performance diesel builder. “For a hot street truck, stainless works great. For a pulling tractor seeing 100+ PSI of boost, we go straight to Inconel. The extra cost is worth not lifting a head during competition.”

Installation Requirements and Procedures

Installing fire rings isn’t a bolt-on modification – it requires precision machine work and careful attention to detail. This is not a parking lot fix or something you can do with basic hand tools. Let’s walk through what’s actually involved.

Machining Requirements:

Receiver Grooves:

- Must be cut into head, block, or both

- Typical depth: 0.025-0.050″ depending on ring

- Width must match ring diameter plus 0.002-0.005″

- Location critical: centered on cylinder bore

- Surface finish: 30 RA or better

- Absolutely must be concentric and flat

Equipment Needed:

- Dedicated fire ring cutting equipment

- Or a CNC machining center

- Precision measuring tools

- Surface finish comparators

- Depth micrometers

The Installation Process:

Step 1: Surface Preparation

- Both surfaces must be perfectly flat (0.002″ max)

- Required finish: 30-60 RA for MLS gaskets

- May need to resurface after cutting grooves

- Cleanliness is absolutely critical

Step 2: Groove Cutting

- Set up the cutting equipment with precise centering

- Cut to the exact depth specification

- Maintain consistent depth around the entire groove

- Deburr carefully without changing dimensions

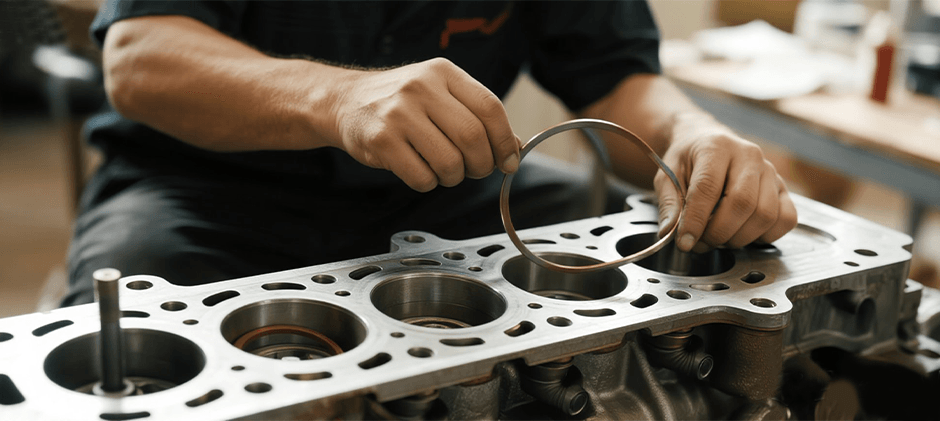

Step 3: Ring Installation

- Clean rings thoroughly

- Check ring gap (some designs require a specific gap)

- Install rings with a gap positioned per the manufacturer

- Verify proper protrusion (typically 0.005-0.010″)

Step 4: Gasket Selection

- Must use a compatible head gasket

- Some gaskets are designed specifically for fire rings

- May need to modify the standard gasket

- Ensure gasket thickness accounts for ring protrusion

Step 5: Assembly

- Follow the specific torque sequence

- May require different torque specs

- Retorque is often required after heat cycling

- Monitor for any sealing issues

“Fire ring installation is not a DIY job unless you have serious equipment,” warns a machine shop owner. “I’ve seen too many botched attempts where someone tried to cut grooves with a die grinder. You need concentricity within 0.001″ or you’ll never seal.”

Benefits and Drawbacks of Fire Ring Head Gaskets

Like any modification, fire rings come with both advantages and disadvantages. Understanding these helps you make an informed decision about whether they’re right for your application.

Benefits of Fire Rings:

Superior Combustion Sealing:

- Handle 3,000+ PSI cylinder pressure

- Eliminate blown head gaskets in high-boost applications

- Allow for more aggressive tuning

- Consistent sealing over the long term

Temperature Resistance:

- Unaffected by extreme combustion temps

- No gasket material to burn or deteriorate

- Maintain the seal during extended high-load operation

Longevity:

- Properly installed rings last the engine’s lifetime

- No compression loss over time

- Reusable if the engine is disassembled

Performance Enabler:

- Safely run higher boost pressures

- Support bigger injectors and more fuel

- Essential for competition applications

- Peace of mind for modified engines

Drawbacks to Consider:

Cost:

- Machine work: $500-1,500

- Rings themselves: $150-500

Special gaskets: $200-400 - Total investment: $1,000-2,500+

Complexity:

- Requires precision machine work

- Not all shops are equipped to install

- More complex assembly process

- May require custom parts

Not Reversible:

- Once grooves are cut, you’re committed

- Must always use fire rings

- Can’t go back to standard gaskets

- Affects resale to some buyers

Potential Issues:

- Poor installation causes leaks

- May require frequent retouching

- Copper rings need more maintenance

- Can leak if surfaces aren’t perfect

“Fire rings are like insurance,” explains a diesel performance specialist. “You pay up front, but when you’re making serious power, they’re worth every penny. I’ve seen standard head gaskets fail at 45 PSI boost. With fire rings, we run 80 PSI all day long.”

When to Consider Fire Rings for Your Diesel

Not every diesel needs fire rings – in fact, most don’t. But certain applications practically demand them. Here’s how to determine if your engine could benefit from this upgrade.

Applications That Need Fire Rings:

Competition Use:

- Truck and tractor pulling

- Drag racing

- Sled pulling

- Dyno competition

- Any motorsport with extreme cylinder pressures

High-Performance Street:

- 50+ PSI boost pressure

- Compound turbo setups

- 800+ horsepower builds

- Nitrous oxide systems

- Extreme towing applications

Problem Engines:

- Repeated head gasket failures

- Known weak head gasket designs

- Engines with insufficient head bolts

- High-mileage engines are getting built

Specific Examples:

- 6.0L Powerstroke making over 500hp

- 12V Cummins with aggressive timing

- Duramax running big twins

- CAT 3406E in competition pulling

- Any diesel pushing limits

When Fire Rings Aren’t Necessary:

Stock or Mild Builds:

- Factory power levels

- Basic programmer/tuner

- Single turbo under 40 PSI

- Daily driver reliability focus

Cost-Sensitive Applications:

- Budget builds

- Temporary fixes

- Engines near the end of their life

- Resale concerns

How to Decide:

Ask yourself:

- Have I blown head gaskets before?

- Am I pushing over 45 PSI boost?

- Is this a competition build?

- Can I afford the machine work?

- Do I have access to qualified installers?

“If you’re questioning whether you need fire rings, you probably don’t,” shares a veteran builder. “But if you’re consistently lifting heads or planning big power, stop wasting money on head gaskets and do it right with fire rings.”

Cost Considerations and ROI

Let’s talk real numbers. Fire rings represent a significant investment, but for the right application, they pay for themselves quickly. Here’s what you’re really looking at cost-wise.

Initial Investment Breakdown:

Machine Work:

- Groove cutting: $75-150 per cylinder

- 6-cylinder diesel: $450-900

- 8-cylinder diesel: $600-1,200

- May need deck resurfacing: Add $300-500

Fire Rings:

- Stainless steel set: $150-300

- Copper set: $200-350

- Inconel set: $400-800

- Premium designs: Up to $1,000

Additional Costs:

- Special head gaskets: $200-400

- Enhanced head studs: $400-800

- Professional installation: $500-1,000

- Shipping heads to machine shop: $100-200

Total Investment: $1,500-3,500 typical

Comparing Alternatives:

Standard head gasket replacement:

- Parts: $150-400

- Labor: $1,000-2,000

- Total: $1,150-2,400

But if you’re blowing gaskets repeatedly:

- 3 failures = $3,450-7,200

- Plus downtime costs

- Plus, potential engine damage

ROI Calculation:

For a truck making 600+ horsepower:

- Without fire rings: Gasket failure every 20,000-50,000 miles

- With fire rings: No failures for the life of the engine

- Break-even: Usually 1-2 prevented failures

Hidden Value:

- Confidence to run harder

- No roadside failures

- Ability to increase power further

- Higher resale in the performance market

- No catastrophic failure risk

“I spent $2,500 on fire rings for my pulling truck,” reports one competitor. “That was five years and hundreds of hooks ago. I’ve watched guys spend that much on head gaskets every season. Do the math.”

Making the Fire Ring Decision

Fire rings represent a significant evolution in diesel engine sealing technology. For the right applications – high-boost, competition, or problematic engines – they’re not just an upgrade, they’re essential. But they’re not for everyone, and understanding when they make sense is crucial.

At FridayParts, we’ve helped thousands of customers make the right sealing decision for their diesel engines. Whether you need standard head gaskets, MLS upgrades, or complete fire ring kits, we stock quality options for all major diesel engines. Our experienced team can help you evaluate whether fire rings make sense for your specific application and guide you to the right supporting components.

Key Takeaways:

- Fire rings provide ultimate combustion sealing for extreme applications

- Professional installation is mandatory – this isn’t a DIY upgrade

- Cost is significant, but ROI is quick for problem engines

- Not necessary for stock or mild builds – match the solution to the need

- Material and design matter – choose based on application

- Once committed, you’re all in – no going back to standard gaskets

Whether you’re building a competition puller, solving chronic head gasket failures, or just want the peace of mind that comes with bulletproof sealing, fire rings might be your answer. Just remember: like any performance modification, success comes from proper installation and quality components.

Fix it once, fix it right – sometimes that means stepping up to fire rings. Your diesel works hard for you; give it the sealing solution it deserves.

Need fire rings or head gaskets for your diesel? FridayParts stocks complete sealing solutions for all major diesel engines. From standard gaskets to complete fire ring kits, we have the parts and expertise to keep your diesel sealed tight. With 16 years of experience and worldwide shipping, we’re your trusted source for diesel engine parts. Visit FridayParts.com – because proper sealing keeps you running.