Ensuring safety is always a big problem in heavy machinery, while the air brake is one of the most important parts. It varies from the standard hydraulic brake, which can’t offer the force that heavy machines need.

This guide will help you learn what the air brakes are, from their working process, key components, to the future maintenance methods, as well as the comparison against traditional oil brakes.

What Are Air Brakes?

An air brake system is a powerful type of friction brake for heavy vehicles that uses compressed air, rather than hydraulic fluid, to operate. If you operate or work around the following equipment, you are already familiar with it:

- Commercial Trucks

- Buses

- Trains

- Heavy-Duty Construction and Agricultural Machinery

From a driver’s perspective, a modern air brake system isn’t just one system; it’s actually three integrated systems working together to ensure control and safety:

- The Service Brake System: This is the primary system you use for normal driving. When you press the brake pedal during operation, the service brake system applies and releases the brakes to slow down or stop the vehicle.

- The Parking Brake System: This system is used to hold the vehicle stationary. When you use the parking brake control (often a yellow, diamond-shaped knob on the dashboard), it releases the air pressure, allowing powerful springs to apply the brakes and prevent the vehicle from moving.

- The Emergency Brake System: This is a critical safety feature that uses parts of both the service and parking brake systems. In the event of a catastrophic air pressure loss or brake system failure, the emergency system automatically engages the brakes to bring the vehicle to a stop.

This multi-part system is genius for its fail-safe design. Unlike the hydraulic system, the air brake system can handle well even if the system loses air pressure, ensuring a critical leak comes to a stop rather than losing its brakes entirely.

The Air Brake Working Process

Understanding how air brakes work can be counterintuitive because they operate on a principle of air pressure release. Here’s a breakdown of the process:

1. Brakes Released

- The air compressor fills the system with air pressure.

- This pressure pushes against a diaphragm in the brake chambers, holding powerful springs in a compressed state.

- With the springs held back, the brakes are disengaged, and the wheels can spin freely.

2. Brakes Applied

- The driver presses the brake pedal, which releases air from the brake chambers.

- With the air pressure gone, the powerful springs expand, pushing a rod that forces the brake shoes against the brake drum.

- This friction slows and stops the vehicle. The more air released, the greater the braking force.

3. Brakes Released

- The driver releases the brake pedal.

- Air from the storage tanks is sent back into the brake chambers.

- This renewed pressure compresses the springs again, pulling the brake shoes away from the drum and allowing the wheels to rotate.

Preventive Maintenance of Air Brakes

Poorly maintained air brakes are a massive safety hazard. Regular checks are not just recommended; they are critical for safe operation.

- Drain the Air Tanks Daily: The compression process creates moisture, which collects as water in the air tanks. In cold weather, this water can freeze and block air lines, potentially causing brake failure. Even though many modern systems have automatic drain valves, manual draining is a crucial daily check.

- Check Air Pressure Buildup: Before driving, ensure the air compressor builds pressure correctly. For a typical truck, the pressure should rise from 85 to 100 PSI in under two minutes with the engine at a fast idle (600-900 RPM).

- Test the Governor Cut-In and Cut-Out: The air compressor governor should stop the compressor at around 120-135 PSI (cut-out) and restart it when pressure drops by 20-25 PSI (cut-in). Listen for the “psss” sound of the governor cutting out.

- Check for Air Leaks: When the system is filled, shut down the engine, loosen the parking brake, and use your ear to hear if there is a leaking sound. A system with good maintenance should not let pressure run away too quickly.

- Inspect Hoses and Couplers: From time to time, must examine all the air pipes if got cracks, wear, or damage. The trailer’s gladhand seal must be kept clean and not broken, so can to avoid the leaking happening.

- Monitor Brake Adjustment: While most systems have automatic slack adjusters, they still need to be checked regularly to ensure the brakes apply evenly and do not drag.

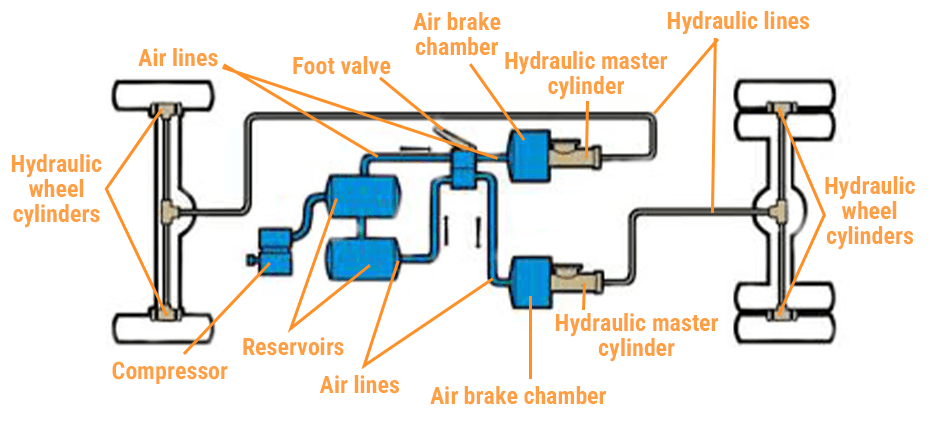

Key Components of an Air Brake System

- Air Compressor: The engine-driven pump that generates the compressed air for the system.

- Air Compressor Governor: Controls when the air compressor starts and stops pumping to maintain a set pressure range in the tanks.

- Air Reservoir Tanks: Steel tanks that store the compressed air. Heavy vehicles have multiple tanks for redundancy.

- Air Dryer: Removes moisture and oil from the compressed air before it enters the tanks, preventing freezing and corrosion.

- Foot Valve (Brake Pedal): The valve operated by the driver’s foot to release air from the brake chambers, applying the brakes.

- Brake Chambers: A cylindrical container at each wheel that houses the diaphragm and the powerful spring that applies the brake.

- Push Rod: This steel stick is what ties the brake chamber inside the diaphragm together with the slack adjuster.

- Slack Adjuster: This arm piece joins the push rod and brake S-cam. It can adjust itself to compensate for when the brake shoe is already wearing down.

- S-Cam & Brake Shoes: The S-cam rotates to force the brake shoes against the brake drum, creating the friction needed to stop the vehicle.

Air Brakes Vs. Oil Brakes: What’s the Difference?

| Feature | Air Brakes | Hydraulic (Oil) Brakes |

|---|---|---|

| Power Source | Compressed Air | Hydraulic Fluid |

| Braking Force | Extremely high, suitable for stopping massive loads. | Moderate, suitable for passenger cars and light trucks. |

| Fail-Safe Design | Yes. Loss of pressure causes the brakes to engage automatically. | No. A fluid leak results in a complete loss of braking power. |

| Complexity & Cost | More complex, with more components and a higher cost. | Simpler, more compact, and less expensive. |

| Response Time | Slight delay (“brake lag”) as air is compressible. | Nearly instantaneous response, as fluid is not compressible. |

| Maintenance | Requires daily draining of air tanks and regular system checks. | Requires periodic fluid changes and bleeding. |

Summary

Standard heavy machinery must be equipped with air brake systems to ensure your safety. Although it’s more complicated and requires rigorous maintenance, its ability to control immense weight makes it worthy. Follow this guide, maintain your air brake system regularly and carefully. For any issues and key components related, FridayParts will cover you.