The undercarriage system of the excavator is a complicated construction, composed of tracks, rollers, and gears, which can be regarded as the “leg” and the “foot” of the machine. It is bearing the whole weight of the machine body, providing the traction on the most rugged terrains, and at the same time ensuring the stability that is demanded for the lifting of the heavy objects. Because this system is occupying a great portion inside the life-long maintenance cost of the machine, therefore, for any owner or operator who is wishing to extend to the maximum degree the normal running time of the machine and to protect his investment, it is being of extreme importance to understand its components and to carry out the proper maintenance.

What is an Undercarriage?

The undercarriage resembles the leg and the foot of the excavator. It is the entire component beneath the machine’s outer shell (the cab, the engine, and the boom), by which the supporting and moving ability is provided. This framework bears the entire weight of the excavator, providing the traction required for movement on the construction site and ensuring the stability necessary for digging and lifting heavy objects. Although the configuration differs, the great majority of excavators are adopting the track system, which consists of a steel link, a pin shaft, a roller, and a sprocket, designed to achieve maximum durability and performance on rugged terrain.

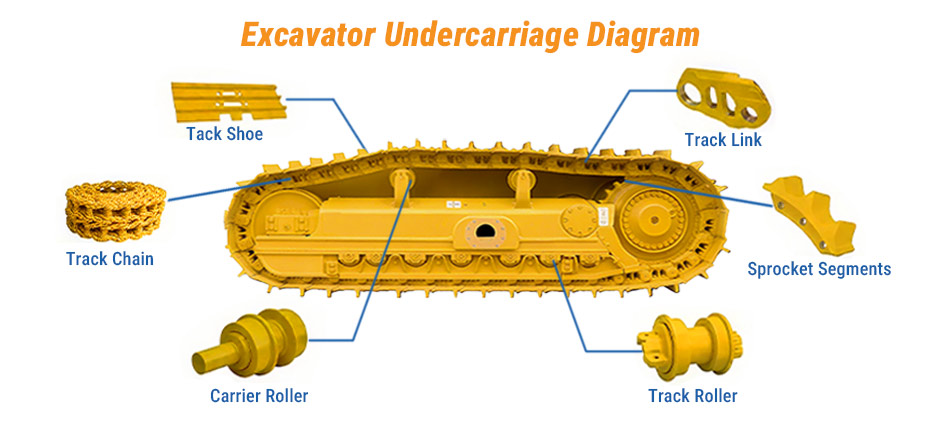

Excavator Undercarriage Components

To apprehend the matter of maintenance, one must beforehand acquaint oneself with the essential components. The undercarriage system of the excavator is constituted as a system formed by parts interlinked with one another, each part bearing its own particular fu

- Track Chains (or Track Links): This is the backbone of the system. It’s a series of interconnected steel links held together by hardened pins and bushings. The track chain is what engages with the sprocket to drive the machine and forms the path for the rollers.

- Track Rollers (or Bottom Rollers): These are the wheels located along the bottom of the track frame. Their job is to carry the entire weight of the excavator and distribute it across the track chain. They guide the track chain and allow it to roll smoothly along the ground.

- Carrier Rollers (or Top Rollers): Located on the top of the track frame, these smaller rollers support the weight of the track chain as it returns from the idler back to the sprocket. They prevent the track from sagging excessively and hitting the track frame.

- Sprockets: This is the drive gear. It is connected to the final drive motor and has teeth that mesh with the bushings of the track chain. As the sprocket rotates, it pulls the track chain and propels the excavator forward or backward.

- Front Idlers: This is the large wheel at the opposite end of the undercarriage from the sprocket. Its main purpose is to guide the track chain and, along with the track adjuster, maintain the correct track tension.

- Track Adjuster: This is a hydraulic cylinder or grease-filled mechanism connected to the front idler. By pumping grease into the adjuster, you push the idler forward, tightening the track. Releasing the grease allows the idler to move back, loosening the track.

How do These Undercarriage Components Work Together?

These individual parts form a synchronized mechanical system to move tons of steel with precision. Here’s how it works:

- The operator engages the travel motors.

- The final drive motor turns the sprocket.

- The teeth of the sprocket engage with the bushings of the track chain, pulling the chain around the track frame.

- As the chain moves, the track shoes bolted to it are laid down on the ground, providing traction.

- The full weight of the excavator is transferred through the track frame to the track roller set, which rolls along the inside of the track chain like a train on a track.

- The chain continues around the front idler, which guides it and keeps it aligned.

- As the chain moves along the top of the frame, its weight is supported by the carrier roller set, preventing it from sagging.

- The chain then returns to the sprocket to complete the loop.

This entire system is what makes up the complete crawler undercarriage, a robust platform that allows the excavator to navigate challenging terrain where wheeled machines could never go.

How Long Does an Excavator Undercarriage Last?

This is the multi-thousand-dollar question, and the answer is: it depends. While a general estimate for a well-maintained undercarriage is between 4,000 and 6,000 operating hours, this range is massive for a reason. The actual lifespan is determined by three key factors:

- Application and Terrain: Where you work is the biggest factor. An undercarriage working exclusively in soft soil will last thousands of hours longer than one working in a rock quarry or on abrasive demolition sites. Hard, sharp materials accelerate wear on all components.

- Operator Habits: A skilled operator can double the life of an undercarriage. Poor habits are costly.

- Maintenance Practices: A consistent maintenance routine is your best defense against premature wear.

| Factor | High Wear (Shorter Life) | Low Wear (Longer Life) |

|---|---|---|

| Terrain | Hard rock, sharp debris, abrasive sand, sticky mud. | Soft soil, loam, grass. |

| Operator Turns | Constant sharp turns and counter-rotating (spin turns). | Wide, gradual turns. |

| Travel Speed | Always traveling in high-speed mode. | Use low-speed travel unless necessary. |

| Travel Direction | Excessive travel in reverse (wears bushings and sprockets faster). | Primarily traveling forward. |

| Work Style | Using the tracks to push or rip material. | Using the tracks for positioning only. |

Undercarriage Maintenance and Repair

Since you can’t always control the terrain, maintenance and operator discipline are your keys to saving money. Here are the essential tasks.

1. Keep it Clean

This is the most important and cheapest maintenance task. Mud, dirt, and debris packed into the undercarriage add weight, increase friction, and can cause components to seize. In cold climates, frozen mud can act like concrete, stopping rollers from turning and grinding flat spots on them. A 10-minute cleaning at the end of the day can save you thousands in repairs.

2. Conduct Daily Inspections

Before starting work, do a quick walk-around. Look for:

- Loose or missing bolts on the track shoes.

- Leaking seals on rollers or idlers (visible oil streaks).

- Cracked or bent track shoes.

- Sprocket teeth that are worn to a sharp point.

- Anything that looks out of place. Catching a small problem early prevents a big failure later.

3. Maintain Proper Track Tension (Sag)

This is critical. A track that is too tight creates immense friction and load, rapidly wearing out pins, bushings, rollers, idlers, and sprockets. A track that is too loose can cause the track to “derail” from the idlers and rollers, causing major damage and dangerous downtime. Check your operator’s manual for the correct amount of “track sag” and how to adjust it using the track adjuster.

4. Promote Good Operating Habits

Train your operators to:

- Make wide, gentle turns instead of sharp pivot turns.

- Minimize high-speed travel and unnecessary movement.

- Avoid excessive travel in reverse.

- Plan their movements to reduce the total distance traveled.

When a component finally does wear out, replacing it promptly is key to protecting the rest of the system. A worn sprocket, for example, will quickly ruin a new track chain. Fortunately, you don’t need to pay high dealer prices. A trusted aftermarket parts supplier can provide high-quality, durable undercarriage components at affordable prices, helping you get back to work without breaking the budget.

Manage Your Undercarriage Now!

The undercarriage of the excavator is a most significant investment, and the effective management thereof is the central element for a profitable operation. By means of unceasing cleansing, the daily inspection, and the cultivation of proper operating habits, one may remarkably prolong the service life of these essential components. When the replacement becomes an inevitability, at FridayParts you may obtain the vast stock of parts, which are of superior quality and at the same time of an affordable price. This shall ensure that you are enabled to replace the worn components in a manner both swift and economical, thereby extending the machine’s uptime to the utmost degree and safeguarding your profitability.