Owners of off‑road machinery often wonder whether their machines even use transfer case fluid. The short answer is yes — though not every heavy piece of equipment includes a transfer case, many 4WD loaders, graders, and agricultural tractors rely on one. These systems divide power between axles, demanding specialized lubrication that regular transmission oil can’t handle. In this guide, we’ll explain what the fluid does, how often it needs replacement, how it differs from transmission oil, and which types of equipment use it. By the end, you’ll know exactly how to check and maintain your system for longer component life.

What is Transfer Case Fluid?

A transfer case is the gearbox that splits engine torque between multiple axles in a four‑wheel‑drive (4WD) or all‑wheel‑drive (AWD) machine. It contains a set of gears, chains, and bearings that generate heat and friction under continuous load. Transfer case fluid (also called transfer case oil) is the lubricant that cools and protects those internal parts.

There are two major forms of transfer case fluid:

- Conventional fluid, refined from petroleum, is used in older mechanical systems.

- Synthetic fluid, formulated in laboratories for consistent viscosity and greater temperature tolerance.

During heavy off‑road work — such as hauling gravel, operating in mud, or climbing steep terrain — the transfer case endures extreme torque. The fluid prevents metal‑to‑metal contact, removes heat, and suspends fine wear particles.

Pro Tip: While some older equipment might have used standard automatic transmission fluid (ATF) or gear oil, most modern heavy machinery requires a specifically formulated transfer case fluid. Always consult your machine’s service manual to ensure you are using the correct type.

How Often to Change Transfer Case Fluid?

You should change your transfer case fluid every 30,000 to 60,000 miles under normal conditions — a guideline your owner’s manual can confirm. However, for machines that tow, operate off-road, or run constantly under load, the interval shortens to around 20,000 miles. These figures come from on‑road systems, but off‑road environments operate differently.

Unlike regular vehicles, off‑road machinery such as wheel loaders, 4WD tractors, and articulated haulers doesn’t measure performance in kilometers or miles. These machines often spend hours idling, digging, or carrying full loads without covering much distance. Because wear depends more on torque and operating hours than on travel distance, service intervals are tracked by engine or drivetrain hours instead of mileage.

| Operating Environment | Suggested Change Interval | Approximate Equivalent |

|---|---|---|

| Light duty (gravel grading, low traction) | Every 500 hours | ~25,000–30,000 miles* |

| Regular off‑road hauling | Every 300–400 hours | ~20,000–25,000 miles* |

| Column 1 Value 3 | Column 2 Value 3 | Column 3 Value 3 |

*Equivalents are rough comparisons for machines that maintain a steady work cycle; in practice, hours provide more accurate scheduling for non‑road vehicles.

By scheduling service based on real operating hours instead of distance, you align your maintenance practice with the actual mechanical stress your off‑road machinery experiences. This proactive approach helps prevent overheating, seal damage, and the high cost of transfer case replacement later on.

A typical transfer case fluid change involves these steps:

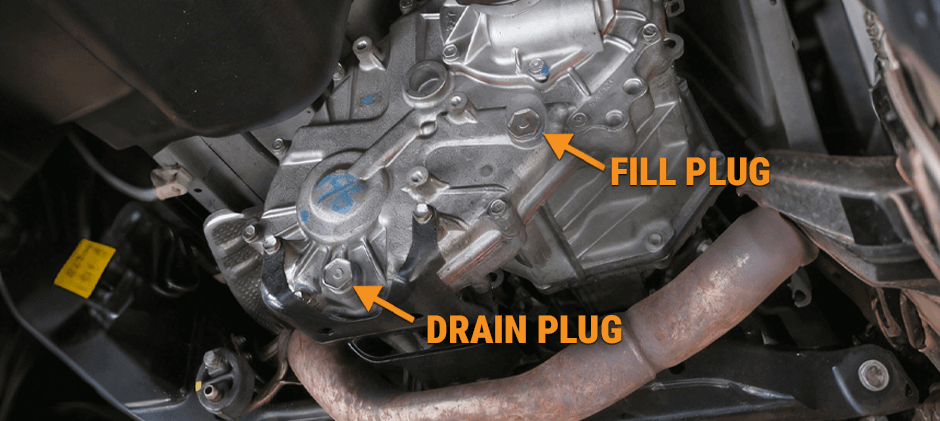

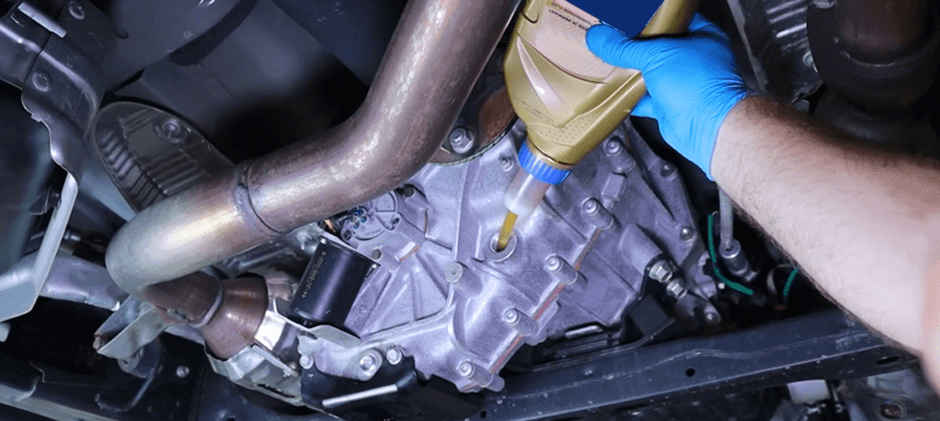

- Drain the old fluid completely using the lower drain plug.

- Inspect the magnet for metal debris or sludge.

- Refill with manufacturer‑approved oil to the specified level.

- Replace sealing washers to avoid future leaks.

This preventive task takes less than an hour but can save thousands in repairs.

Is Transfer Case Fluid the Same as Transmission Fluid?

The similarity in name causes confusion, yet transfer case fluid and transmission oil serve different purposes and chemical compositions.

| Feature | Transfer Case Fluid | Transmission Fluid |

|---|---|---|

| Main Function | Cools and lubricates rotational gears, distributing torque to axles | Enables gear shifting within the transmission |

| Viscosity | Usually thicker (75W‑85, 80W‑90) | Thinner (ATF‑type) |

| Typical Color | Amber, brown, or light blue | Red or dark pink |

| Change Frequency | 20,000–50,000 miles or 300–500 hrs | 30,000–60,000 miles or 600+ hrs |

| Interchangeable? | No – only some units are designed for ATF use | Not suitable for transfer cases requiring heavy‑load lubrication |

Mixing the two can reduce lubrication film strength, leading to heat buildup and gear damage. Always use the oil type described for your specific drivetrain. Some heavy‑duty models even use dedicated transfer case oil meeting GL‑5 standards for extreme pressure.

What Equipment Needs Transfer Case Fluid?

Not every heavy machine requires it, but any off‑road equipment with a multi‑axle drive system will include a transfer case. Below are common examples:

| Equipment Type | Drive Type | Transfer Case Fluid Requirement |

|---|---|---|

| 4WD Agricultural Tractor | Mechanical front wheel drive (MFWD) | Yes |

| Articulated Wheel Loader | Central torque divider (Power Divider) | Yes |

| Motor Grader with 6×6 drive | Hydraulic and mechanical combo | Yes |

| Compact Excavator | Hydraulic travel motors | No |

| Bulldozer | Direct final drives, no split box | No |

| All‑terrain Haul Truck | Full‑time all‑wheel drive | Yes |

Off‑road powertrains rely on this fluid for synchronized wheel traction. When you operate in low‑grip terrain or uneven topography, torque transfer balance is vital — clean fluid ensures smooth shifting between drive modes and protects seals from grit contamination.

Midway through your equipment life cycle, you might also need to replace related powertrain components such as sprockets, shafts, or seals. For high‑quality aftermarket replacements, explore our wide inventory of transmission & undercarriage parts compatible with most off‑road brands. Our solutions provide OEM‑equivalent performance at prices that keep maintenance budgets in check.

Pro Tips for Off‑Road Operators

To extend the life of your transfer case fluid and reduce downtime:

- Warm up your machine before engaging 4WD under heavy load.

- Avoid running excessive torque angles for long periods.

- Inspect breather vents; blocked vents cause internal pressure that pushes fluid out through seals.

- Replace companion components when overhauling — a worn output bearing can contaminate new fluid instantly.

If you hear clicking from the driveline or experience jerky gear engagement, consider inspecting the transfer case chain and lubrication channels. Changing your fluid early is cheaper than waiting for a gearbox rebuild.

Keep Power Flowing Smoothly

Changing your transfer case fluid isn’t optional; it’s a vital habit for anyone who depends on off‑road machinery to haul, grade, or dig reliably. Fresh fluid safeguards your drivetrain so torque reaches every wheel without stress. For your repair or upgrade projects, choose high‑quality aftermarket parts that balance durability and affordability. FridayParts offers transmission & undercarriage parts engineered for a wide range of heavy equipment, helping you maintain maximum uptime no matter where your job takes you.