Ignoring flashing or unfamiliar icons on a Toyota forklift’s dashboard can lead to confusion, downtime, and even costly damage. This guide details the various symbols and warning lights on your Toyota forklift’s dashboard, explaining the meaning of each symbol, its color codes, and how to respond when they illuminate, as well as how to prevent recurrence. This will help you drive your Toyota forklift more effectively.

Toyota Forklift Symbols and Their Meanings

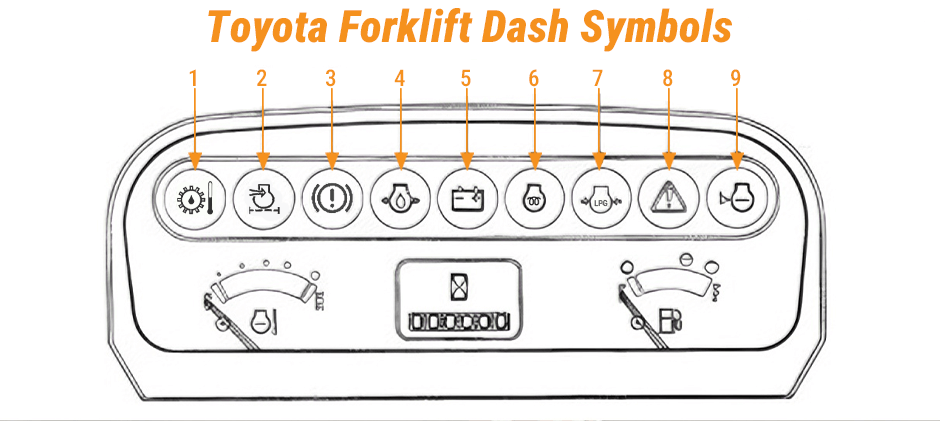

A Toyota forklift’s dashboard isn’t just decoration. Each indicator gives you vital information about fuel, fluid levels, electrical systems, and safety conditions. Below is a simplified reference table for common dashboard symbols and their meanings.

| No | Indicator Light | Meaning When ON or Flickering | Action Required |

|---|---|---|---|

| 1 | Powershift Transmission Oil Temp | Transmission overheating | Stop the operation and allow the system to cool down |

| 2 | Air Cleaner Element | Air filter clogged | Inspect or replace the air filter immediately |

| 3 | Brake Fluid Level | Brake fluid low | Check and refill the brake fluid reservoir |

| 4 | Engine Oil Pressure | Oil pressure low | Stop the engine, check the oil level, and refill if needed |

| 5 | Alternator Charging | Charging system fault | Inspect the alternator belt and electrical connections |

| 6 | Heater Plug | Diesel model pre-heating | Normal when starting a diesel engine |

| 7 | LP-Gas Residual Pressure | Low fuel pressure | Check the LPG tank and connection |

| 8 | System Indicator | ECU or system fault detected | Perform a diagnostic scan |

| 9 | Engine Coolant Level | Coolant low | Refill coolant and inspect for leaks |

Ignoring any of these warnings can result in costly repairs or system failure. Most of these alerts indicate developing issues that are simple to fix if addressed promptly.

Common Toyota Forklift Dashboard Warning Lights

Each Toyota forklift comes equipped with a set of critical system warning lights designed to protect both machine and operator. Understanding their meanings is essential for daily operation.

1. Battery Warning Light

Symbol: A red battery icon with “+” and “–”

Meaning: The electrical system is not charging properly.

Possible Causes:

- Loose or corroded terminal cables

- A failing alternator

- Broken belt or aging battery

Operator Action: Shut down equipment, tighten all connections, and inspect charge output. Replace the alternator or battery with OEM‑grade Toyota parts to ensure a lasting power supply.

Pro tip: Avoid jump‑starting repeatedly; it overloads sensitive circuits and reduces alternator life.

2. Engine Oil Pressure Warning Light

Symbol: Oil canister dripping oil

Meaning: Low oil pressure or insufficient oil circulation.

Possible Causes:

- Low oil level, pump failure, or clogged oil filter.

Operator Action: Stop the engine. Wait for pressure to normalize after checking oil levels. Replace the oil filter if dirty. Continuous low pressure can cause piston seizure — one of the costliest failures.

3. Temperature / Coolant Warning Light

Symbol: Thermometer in fluid

Meaning: Engine temperature exceeds safe operating range.

Possible Causes:

- Coolant leak

- Radiator blockage

- Faulty thermostat or fan

Operator Action: Stop the forklift immediately and inspect coolant levels. Clean radiator fins. If the light remains on, the cooling system needs attention — replace worn components using trusted Forklift parts to restore performance.

4. Hydraulic Oil Warning Light

Symbol: Oil droplet or hydraulic cylinder icon

Meaning: Hydraulic fluid is low or contaminated.

Possible Causes:

- System leaks, a clogged hydraulic filter, or overheated fluid.

Why It Matters: Ignoring this warning can lead to jerky lifting, unstable mast operation, or total hydraulic failure.

Operator Action: Cool the hydraulic system before topping up. Use manufacturer-approved fluids to maintain pressure stability and avoid cavitation.

5. Brake Warning Light

Symbol: Circle enclosing an exclamation mark or “BRAKE” text

Meaning: A problem within the braking system.

Possible Causes:

- Low brake fluid

- Air in brake lines

- Worn pads or malfunctioning sensors

Operator Action: Check fluid and add the appropriate DOT type. Inspect pads and lines for leaks. If the light remains illuminated, stop operation until a technician evaluates it—brakes are mission‑critical.

6. Transmission Warning Light

Symbol: Gear with an exclamation mark

Meaning: Transmission oil overheating, contaminated fluid, or gear mechanism fault.

Operator Action: Pause operation, check transmission fluid level, and look for leaks. Replace burned or dark fluid immediately. Consistent overheating means the clutch or planetary gears may need servicing.

7. Air Filter Warning Light

Symbol: Filter or fan icon

Meaning: Air filter clogged, restricting air intake.

Why Important:

- A dirty filter raises fuel consumption and reduces engine torque.

Operator Action: Clean or replace the filter element regularly. If using forklifts in dusty environments, shorten the cleaning interval to half of the normal cycle.

8. Tilt Warning Light

Symbol: Forklift with tilted mast

Meaning: Excessive tilt angle or unbalanced load detected.

Operator Action: Stop lifting and check load stability. Rebalance the weight and level the forks before resuming. If the warning stays on, test the tilt sensor or locking mechanism — they may need calibration or replacement.

9. Seatbelt Warning Light

Symbol: Person wearing a seatbelt

Meaning: Operator not properly buckled or seat sensor malfunction.

Operator Action: Fasten the seatbelt securely; the light should turn off within seconds. Check the buckle switch if the warning persists.

Safety First: Forklift seatbelt alerts are often linked to the safety interlock system — your machine won’t operate effectively until drivers comply.

10. Check Engine Light

Symbol: Engine silhouette with “CHECK” label

Meaning: General malfunction detected by ECU (Engine Control Unit).

Operator Action: Run a diagnostic scan to identify error codes. Common triggers include misfires, faulty injectors, or malfunctioning sensors. Avoid continued use under this warning to prevent damage to the fuel or emission system.

11. Power‑Shift Transmission Oil Temperature Light

Symbol: Gear symbol with thermometer

Meaning: Fluid overheating or lack of cooling flow in the transmission.

Operator Action: Stop lifting operations and cool down. Check fluid quality (burnt smell or dark color indicates degradation). Replace the cooler or filter if needed.

12. LPG Residual Pressure Warning

Symbol: Gas bottle icon or droplet

Meaning: LPG pressure too low or water present in the fuel line.

Operator Action: Secure and refill the gas tank, and drain any condensation from the system. Always check seals and hose ends for cracks if this light reoccurs frequently.

13. Alternator Warning Light

Symbol: Battery icon

Meaning: The system isn’t charging properly.

If this light glows while running, inspect the alternator tension, belt condition, and cabling. Replace the alternator or voltage regulator promptly — a failing alternator can silently drain the battery and halt operation mid‑shift.

14. Master System Light

Symbol: Triangle or exclamation icon on electric models

Meaning: Multiple simultaneous system errors.

Operator Action: Immediately stop the equipment and perform a full diagnostic scan. This light typically means the onboard ECU has detected interconnected faults — electrical, hydraulic, or temperature-related.

The Meanings of Color Codes on Toyota Forklift

Forklift dashboard lights use color codes similar to most heavy machinery indicators:

| Color | Meaning | Typical Action |

|---|---|---|

| Green / Blue | System working normally | No action required — indicator only |

| Yellow / Amber | Caution, maintenance needed soon | Plan an inspection or a routine check |

| Red | Immediate danger or system failure | Stop and troubleshoot before resuming operation |

Color differences help you prioritize: red is critical, yellow is preventive, and green confirms normal function.

How to Respond When a Warning Light Appears?

When a dashboard light comes on, reacting calmly and systematically prevents further damage. Follow these steps:

- Pause Operations – Stop lifting or driving immediately.

- Identify the Symbol – Cross-check with the forklift’s manual or this guide.

- Inspect the Indicated System – Battery, oil, hydraulic fluid, or temperature levels.

- Restart and Observe – Some lights go off after fixing the immediate cause.

- Run a Diagnostic Scan – Use a scanning tool or seek professional service if the light persists.

If replacement or adjustment is required, choose components from certified sellers offering heavy-equipment-grade Forklift parts to ensure compatibility and durability.

Prevent Dashboard Warnings Before They Happen

Keeping dashboard lights off starts with a proactive maintenance routine:

1. Inspect Before Every Shift

Always check engine oil, hydraulic oil, coolant, brakes, and tire condition.

2. Stay Consistent with Filter Changes

Clean air and hydraulic filters allow accurate sensor readings and steady system pressure.

3. Check Battery Health Regularly

Poor battery voltage triggers multiple unrelated warnings. Test charge level monthly.

4. Keep Electrical Connectors Dry and Tight

Moisture or corrosion causes false alarms and short circuits.

5. Monitor Fluid Temperature

Overheated oil or coolant accelerates wear and triggers sensor alerts.

6. Use OEM‑Quality Replacement Parts

Authentic or verified aftermarket components maintain sensor accuracy, prevent bad readings, and ensure durability in challenging work conditions.

FridayParts provides thousands of Toyota forklift parts and aftermarket components compatible with leading off‑road models — designed for reliability, easy installation, and affordability.

Conclusion

Knowing the meaning of every Toyota forklift dashboard symbol lets you respond confidently and maintain your equipment without guesswork. A trained eye and timely action guarantee less downtime and safer operations. When repairs or part replacements become necessary, depend on FridayParts — a trusted supplier of OEM‑quality Toyota and forklift aftermarket parts. From filters and alternators to complete hydraulic assemblies, you’ll find everything you need to keep your equipment working like new.