When an off-road machine throws SPN 100 FMI 1, we should treat it as an engine oil pressure warning—not a “drive it later” message. This code often comes with a stop/check lamp, power derate, and in some setups, an automatic shutdown timer. In this guide, we’ll explain what the code means, why it happens, and how we can diagnose and fix it step by step so the machine gets back to work with less risk.

What is SPN 100 FMI 1 Code?

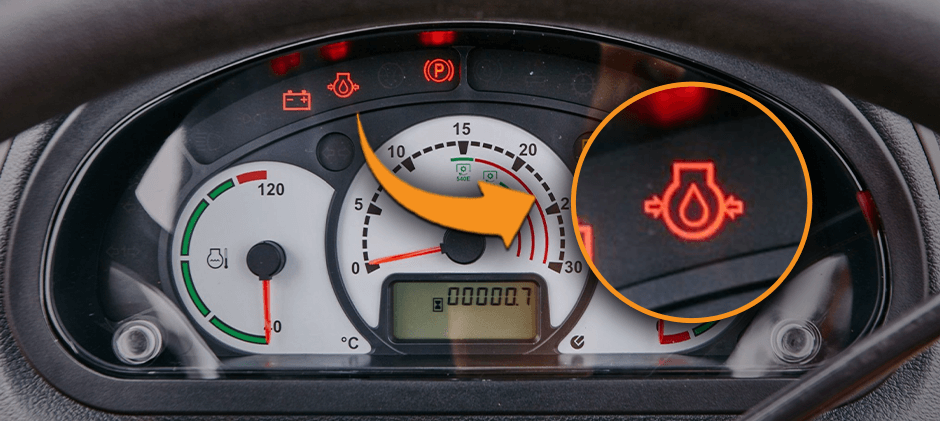

On many heavy equipment engines that use standardized fault reporting, SPN 100 points to engine oil pressure, and FMI 1 generally means the signal is below normal operating range (low oil pressure condition).

In practical terms, the control module is seeing oil pressure that is below its minimum threshold for the current operating conditions. Once that happens, most engines will protect themselves by:

- Turning on a STOP/Check Engine lamp (often immediately)

- Applying a power and/or speed derate

- Triggering engine protection shutdown if that feature is enabled (some systems will shut down after a short countdown)

What we may notice on the jobsite?

Depending on the machine and how the protection is set up, SPN 100 FMI 1 may show up as:

- The warning lamp flashes when the machine comes off idle or changes load

- Brief code that clears on its own (intermittent)

- Persistent alarm with reduced power

- Shutdown warning after the red stop lamp starts flashing

Even if it happens “only for a second,” we still treat it seriously. Intermittent low pressure can be caused by aeration, suction leaks, wiring faults, or a borderline oil pump—issues that can get worse without warning.

Why Does SPN 100 FMI 1 Code Happen?

We can group the causes into two buckets: real low oil pressure and false low-pressure signal. The fix depends on which bucket we’re in, so we don’t want to guess.

A) Real low oil pressure (engine truly has low pressure)

Common real-world causes in off-road machinery:

1. Low oil level

An oil level below the safe range can uncover the pickup on slopes, during braking, or when the machine is bouncing.

2. Wrong oil viscosity for the conditions

Oil that is too thin at operating temperature may not hold pressure at hot idle.

3. Oil diluted or degraded

Fuel dilution, coolant contamination, or long service intervals can drop film strength and pressure stability.

4. Restricted oil filter or filter housing issues

A clogged filter can alter flow behavior; a stuck bypass or drain valve can cause unusual pressure events.

5. Oil pickup tube seal/O-ring sucking air (aeration)

Air in the oil can cause a momentary pressure drop. Aerated oil often shows up as intermittent codes at low RPM.

6. Oil pump wear, damaged pump, or pressure relief valve problems

Worn gears/rotors, scoring, or a relief valve stuck open can reduce pressure, especially when hot.

7. Internal engine wear

Excess bearing clearance can bleed off pressure. This is usually paired with other symptoms (noise, metal in oil, persistently low hot idle pressure).

B) False low-pressure signal (sensor/circuit reports low when pressure is OK)

Typical electrical or sensor-related causes:

- Oil pressure sensor out of range or failing intermittently

- Connector issues: loose fit, corrosion, oil intrusion, bent pins

- Harness chafing, short to ground, or high resistance in the signal/return circuit

- Weak ground or power supply reference issues

- Incorrect calibration or software mismatch (less common, but possible after control updates)

Why do intermittent events happen more at low RPMs

Oil pressure is usually lowest at hot idle or when engine speed drops quickly. If a machine logs SPN 100 FMI 1 right as RPM dips, that pattern often points to:

- borderline hot idle pressure.

- aeration/suction leak that shows up when the pump speed is low.

- a sensor/wiring “glitch” that becomes visible during transitions.

This is a key transition point: before we buy parts, we confirm whether the engine is truly losing pressure.

How to Fix SPN 100 FMI 1?

This is the core work. We’ll move from the safest, fastest checks to the deeper ones. We also want to avoid running the engine if the pressure is truly low.

Safety note: If the stop lamp is on or the machine is derating hard, we should park safely, lower attachments, and follow the equipment manual. Continuing to run with real low oil pressure can damage the engine in minutes.

Step 1: Confirm the complaint and capture freeze-frame data

Before clearing anything, we record:

- Engine hours

- Oil temperature (if available)

- Engine speed at the moment the code is set

- Whether it happened at hot idle, on a slope, during a load change, or after service

If the code is intermittent, these details help us reproduce it.

Step 2: Check oil level, oil condition, and correct spec

This sounds basic, but it solves a lot of cases.

- Verify oil level on level ground (and re-check after waiting a few minutes)

- Look for signs of dilution (thin oil, fuel smell) or coolant contamination (milky oil)

- Confirm the oil grade matches the climate and duty cycle

If the oil is wrong, old, or contaminated, we correct that first. Then we retest.

Step 3: Verify oil pressure with a mechanical gauge (do not skip)

The fastest way to split “real” vs “false” low pressure is a manual gauge.

What we’re doing:

- Install a calibrated mechanical gauge at the proper test port

- Compare readings at:

- cold start

- hot idle

- mid RPM no-load

- under a controlled load (if safe)

If mechanical pressure is within spec but the code still sets, we focus on the sensor/circuit. If mechanical pressure is low, we stay on the lubrication system and internal wear path.

Step 4: Inspect the sensor, connector, and harness (with load testing)

If pressure is good on the gauge:

- Inspect the sensor body for oil leaks and damage

- Unplug and inspect connector pins (spread, bent, corroded, oil-soaked)

- Check harness routing for rub-through and pinch points near clamps and brackets

- Perform circuit checks per service manual:

- reference voltage (if applicable)

- signal voltage behavior

- ground integrity

- continuity and short-to-ground checks

A “looks fine” harness can still fail under vibration. If the issue occurs monthly, we may need to perform a wiggle test and load test the circuit rather than relying on a quick ohm reading.

Step 5: If mechanical pressure is low, work through the lubrication system causes

If the gauge confirms low oil pressure, we move in a logical order:

1. Oil filter and filter housing valves

- Replace the filter with the correct type

- Inspect bypass/drainback valves (sticking can cause pressure events)

2. Pickup tube and suction seals

- Check pickup tube sealing surfaces and O-rings

- Look for cracks or loose fasteners that let air in

3. Oil pump and pressure relief valve

- Inspect for scoring, wear, or a relief valve stuck open

4. Oil passages and restrictions

- Sludge, gasket misalignment, or debris from previous failures can restrict flow

5. Internal wear checks

- If oil pressure stays low hot even after pump/relief checks, we may be looking at bearing clearance or other internal leakage paths

Step 6: Repair strategy—don’t “parts cannon,” but don’t delay obvious wear items

Once we’ve identified the likely root cause, we plan the fix based on downtime and risk. For many off-road machines, common repair parts tied to this code include:

- Oil pressure sensor

- Oil filter and related seals/valves

- Oil pump components

- Gaskets and O-rings in the suction path

- Cooling system parts that prevent chronic overheating (heat drives oil thinning)

If we need reliable replacements without paying OEM-only pricing, it can help to source from a heavy-equipment-focused aftermarket catalog. FridayParts organizes common wear items (fuel system, lubrication & cooling, internal engine parts, overhaul kits), which is useful when we’re trying to get the machine running quickly with correct fitment. Here’s the category: engine parts.

Quick troubleshooting map (fast reference)

| What we observe | Most likely direction | What we check next |

|---|---|---|

| Code sets at hot idle, gauge confirms low pressure | Real low pressure | Oil spec, filter/valves, pickup tube seals, pump/relief |

| Code sets intermittently, gauge pressure OK | False signal | Sensor, connector pins, harness rub, grounds, load test |

| Code sets during slope/braking/rough travel | Oil pickup uncovering/aeration | Oil level, sump baffles (if applicable), pickup seals |

| Persistent derate + stop lamp, pressure very low | High-risk condition | Shut down, diagnose pump/relief/internal wear |

Preventive Maintenance Tips

Once we fix SPN 100 FMI 1, we want it to stay fixed. Off-road machinery runs long hours in dust, heat, and vibration, so prevention is mostly about oil health and leak-free suction.

Our practical checklist

1. Use the correct oil grade for your climate and duty cycle

- Hot jobs and long idles punish oil that is too thin at temperatures.

2. Hold the oil and filter interval (and shorten it if the job is severe)

Dusty sites, high idle time, and frequent regen events can justify tighter intervals.

3. Inspect for aeration signs

- Foamy oil on the dipstick

- Whining noise that changes with RPM

- Intermittent low-pressure codes at low RPM

4. Keep breathers and crankcase ventilation healthy

Excess crankcase pressure can push oil where it shouldn’t go and worsen leaks.

5. Watch the operating temperature

Overheating thins oil and raises failure risk. Cooling system maintenance supports oil pressure stability.

6. After service, verify

After oil/filter changes or engine work, we run a controlled warm-up and confirm no leaks and stable pressure.

Conclusion

SPN 100 FMI 1 is a low engine oil pressure warning that can trigger derate or shutdown on off-road machinery. We fix it by confirming oil level/spec, verifying pressure with a mechanical gauge, and then choosing the right path: lubrication system repairs for really low pressure, or sensor/harness repairs for false signals. Preventive oil, filter, and temperature control reduce repeat events and protect the engine from costly wear.