Seal kits are used to seal the gap between components in the hydraulic cylinder. They play an important role in sealing fluids and preventing contamination. It goes without saying that an improper size of a hydraulic cylinder seal kit can lead to reduced performance or even failure. Please choose the right hydraulic cylinder seal kits by size. Sealing kits usually contain all the seals needed to refurbish the hydraulic cylinder. In this article, we will talk about what you need to know before buying seal kits.

Signs of Worn or Damaged Seals

Worn or damaged seals often have obvious symptoms, which remind you of replacement.

Visible leaks

The most common sign of seal failure is a liquid leak. You may notice hydraulic fluid oozing from the front of the cylinder. In dirty operation surroundings, the leaking liquid rapidly forms dark oily deposits on the cylinder gland. This is a clear visual sign that the piston rod seal has failed.

Hydraulic pressure reduction

People may not immediately feel the loss of hydraulic power. The machine has trouble lifting a load, or its movements become slow. This is usually due to internal leaks. If you have regular stress checks, you’ll notice this problem.

Inconsistent or Jerky Movements

If the cylinder movement becomes uneven, the seal is likely to fail. This is because of unstable oil and the failure of the piston sealing ring, which causes the pressure on both sides of the piston to fluctuate. This instability reduces accuracy and puts additional pressure on other components.

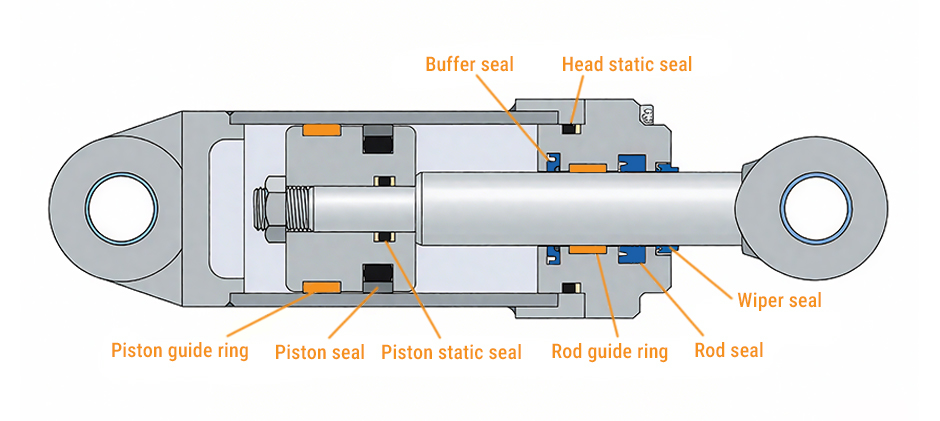

Types of Hydraulic Cylinder Seals

Seals are broadly categorized as either static or dynamic.

-

Static Seals: These are used in locations where there is no movement between parts, such as the seal between the piston and the piston rod. Their job is simply to prevent leakage from a fixed joint.

-

Dynamic Seals: These are designed to function between parts that are in motion relative to each other. They are the workhorses of the sealing system.

The most common seals include:

-

O-Rings: Provide a basic sealing function in static and dynamic applications.

-

Rod Seals: Prevent fluid from leaking along the cylinder rod.

-

Piston Seals: Maintain pressure and prevent fluid from bypassing the piston.

Each seal type is designed for specific applications, so choosing the right one ensures optimal performance. You can refer to the hydraulic cylinder with a diagram. Now that we understand the different components in a kit, let’s focus on the most critical part: getting the measurements right to find the correct hydraulic cylinder seal kits by size.

Select the Right Hydraulic Cylinder Seal Kits by Size

Although some cylinders have part numbers that make ordering easy, these are often worn off or painted over. The most reliable method is to take precise measurements of the cylinder itself. For this, you will need a quality set of calipers and a tape measure. Follow these steps to take the key measurements of your hydraulic cylinder. These dimensions will help you either directly size the required seals.

Step 1: Measure the Bore

The bore is the inside diameter (I.D.) of the cylinder barrel. This is one of the most critical measurements for identifying the correct piston seal. You can most accurately measure the bore with a telescoping gauge or a set of inside calipers after removing the piston. A tape measure is not precise enough for this measurement. Measure the diameter across the inner wall of the cylinder barrel.

Step 2: Measure the Piston Rod

The piston rod is a shaft that moves in and out of the cylinder. The rod seal and wiper seal must match their diameters perfectly. Use a set of outside calipers to measure the outside diameter (O.D.) of the rod. Take measurements in a few different spots and rotate the calipers to check for out-of-round wear, although this is uncommon.

Step 3: Determine the Cylinder’s Retracted Length

The retracted length is the distance between the centers of the two mounting pin holes when the cylinder is fully closed. How to Measure: Use a tape measure to find the center-to-center distance. This measurement, along with the extended length, helps identify the specific model of the cylinder.

Step 4: Measure the Cylinder’s Extended Length

The extended length is the distance between the centers of the two mounting pin holes when the cylinder is fully open. How to Measure: Fully extend the cylinder and use a tape measure to find the center-to-center distance between the pins.

Step 5: Calculate Your Cylinder’s Stroke

The stroke is the total distance the rod travels from the fully retracted to the fully extended position. How to Calculate: Simply subtract the retracted length from the extended length. Formula: Extended Length – Retracted Length = Stroke

Step 6: Perform a Thorough Visual Inspection of Your Hydraulic Cylinder

Measurements are only part of the process. A successful repair must ensure the good performance of other components.

- Rod: Carefully examine the chrome rod for any scratches, pitting, or areas where the chrome is flaking. Run your fingernail over the surface; if you can feel a scratch, it is deep enough to tear a new rod seal. You must re-chrome or replace a damaged rod.

- Bore: Look inside the cylinder barrel for scoring (deep scratches) or gouges. Significant damage to the bore will cause piston seals to fail and will require professional honing or full replacement of the barrel.

- Measure the Old Seals: Once disassembled, carefully remove the old seals. Use your calipers to measure their cross-section and diameter. Comparing these measurements to the specifications of a new kit is the ultimate confirmation that you have the right parts.

Find the Right Hydraulic Cylinder Seal Kits by Size

The key to successful replacement of hydraulic cylinder seal kits lies in careful diagnosis and measurements. Spotting signs of wear early, you take time to measure bore, piston rods, and other components to avoid part errors. For your heavy equipment, a high-quality aftermarket seal kit provides an affordable way. At FridayParts, most brands and models of hydraulic seals have corresponding kits. Choose the reliable parts we need to get you back to work quickly.