What Happens When Rod Bearings Fail?

When rod bearings start to fail, your engine is basically counting down to disaster. These small but mighty components sit between your connecting rods and crankshaft, helping to reduce friction and distribute oil. When they wear out or fail, metal starts grinding on metal – and that’s never good news for your wallet.

Rod bearing failure doesn’t just happen overnight. It’s usually a gradual process that gives you warning signs before the big bang happens. If you ignore these signs, you’re looking at a seized engine, broken connecting rods, and possibly even a cracked engine block. The worst part? A problem that might have cost a few hundred bucks to fix can quickly turn into thousands in repairs or even a complete engine replacement.

The scary thing about rod bearing failure is how quickly it can escalate. One minute your engine is running a little rough, and the next you’re on the side of the road with smoke pouring from under your hood. That’s why knowing the warning signs and taking quick action can literally save your engine’s life.

Common Causes of Rod Bearing Failure

Rod bearings don’t just fail for no reason. Usually, there’s a root cause that, if caught early, can prevent major damage. One of the most common culprits is poor lubrication. When your engine doesn’t get enough oil or the oil quality is poor, bearings suffer from increased friction and heat. This is why skipping oil changes is one of the worst things you can do for your engine health.

Another major cause is contamination. Dirt, metal particles, and other debris can work their way into your oil and act like sandpaper against your bearings. Even tiny particles can cause scoring and accelerated wear. That’s why regular oil and filter changes are so important – they keep your lubrication system clean.

Improper installation is another surprisingly common cause. If bearings aren’t seated correctly during engine assembly or repair, they can shift, causing uneven wear and eventual failure. Similarly, if the crankshaft isn’t properly balanced or aligned, it can put excess stress on certain bearings, leading to premature failure.

Let’s not forget about overloading and over-revving. Pushing your engine beyond its design limits puts enormous stress on rod bearings. This includes hauling loads heavier than recommended, aggressive driving with frequent high RPMs, or modifications that increase power without upgrading supporting components.

7 Warning Signs of Rod Bearing Failure

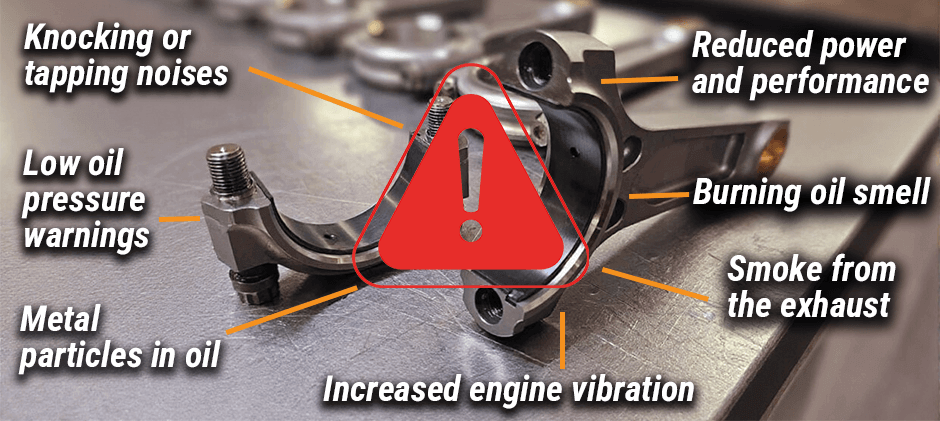

Catching rod bearing problems early can save you from catastrophic engine damage. Here are the seven warning signs you should never ignore:

- Knocking or tapping noises: This is often the first and most obvious sign. You’ll hear a distinct knocking sound that gets louder as engine speed increases. This noise happens because the worn bearing allows excessive movement between the rod and crankshaft.

- Low oil pressure warnings: Worn bearings create larger clearances, which cause oil pressure to drop. If your oil pressure gauge shows lower-than-normal readings or the warning light comes on, take it seriously.

- Metal particles in oil: During your next oil change, look at the drained oil or check the oil filter for metal flakes. These are actually pieces of your bearings being worn away – a definite red flag.

- Increased engine vibration: As bearings wear, they allow more movement in the rotating assembly, causing noticeable vibrations that weren’t there before.

- Reduced power and performance: Failing rod bearings create drag and inefficiency in the engine, resulting in power loss that you’ll feel when driving.

- Burning oil smell: When bearings begin to fail, they generate excessive heat that can burn oil, creating a distinct smell coming from your engine.

- Smoke from the exhaust: In advanced stages of bearing failure, you might see blue or gray smoke from your exhaust as oil leaks past damaged components and burns in the combustion chamber.

If you notice even one of these symptoms, it’s time to take action. The longer you wait, the more damage occurs, and the more expensive your repair bill will be.

How to Diagnose Rod Bearing Issues

Diagnosing rod bearing problems before they lead to catastrophic failure can save you thousands in repair costs. The first step is using your ears – rod bearing issues often announce themselves with distinctive sounds. A rhythmic knocking noise that changes with engine RPM is a classic sign of rod bearing wear. The sound typically gets louder under load and during acceleration.

Oil analysis is another powerful diagnostic tool. For just $25-50, you can send an oil sample to a lab and get detailed information about what’s happening inside your engine. The presence of copper, lead, or aluminum in your oil analysis results often indicates bearing wear long before you’d hear any noise. Many professional fleets use this method for preventive maintenance.

Checking your oil pressure readings can also provide valuable clues. Rod bearing wear creates larger clearances, which causes oil pressure to drop. If your pressure gauge shows lower-than-normal readings, especially at idle, it’s worth investigating further. Similarly, examining your oil filter during changes can reveal metal particles that have broken off from failing bearings.

For a definitive diagnosis, a mechanic might perform a bearing clearance check using a tool called a plastigage. This involves partially disassembling the engine to measure the gap between the bearing and journal. While invasive, this test can confirm bearing wear before committing to a full repair.

The Rod Bearing Replacement Process

Replacing rod bearings isn’t a simple DIY job for most people – it requires partial engine disassembly and precise measurements. The process typically starts with draining all fluids and removing the oil pan to access the bottom end of the engine. From there, the connecting rod caps are carefully removed to expose the bearings.

One of the most critical steps is inspecting the crankshaft journals for damage. Even if you’re replacing the bearings, a scored or damaged crankshaft will quickly destroy new bearings. If the crankshaft shows significant wear, it may need to be removed and reground or replaced entirely.

When installing new bearings, precision is everything. Bearing clearances must be measured using specialized tools to ensure they meet manufacturer specifications. Too tight, and the bearings will overheat; too loose, and they’ll fail prematurely. This is why having this job done by an experienced mechanic is usually worth the investment.

The cost breakdown for rod bearing replacement typically looks like this:

| Component | Cost Range |

|---|---|

| Bearing sets | $50-$300 |

| Gaskets and seals | $50-$150 |

| Labor (8-20 hours) | $800-$2,000 |

| Additional parts if needed | $0-$1,500 |

| Total | $900-$3,950 |

The wide range in cost reflects the difference between a simple bearing replacement on an easily accessible engine versus more complex situations where additional damage has occurred or where the engine design makes access difficult.

Preventing Rod Bearing Failures

The good news is that most rod bearing failures are preventable with proper maintenance. Regular oil changes are your first line of defense – fresh, clean oil provides the lubrication bearings need to survive. Follow your manufacturer’s recommended oil change intervals, and consider shortening them if you drive in severe conditions like extreme temperatures, dusty environments, or frequent short trips.

The type of oil you use matters, too. Always use the viscosity recommended by your engine manufacturer. Using oil that’s too thin won’t provide adequate protection, while oil that’s too thick may not reach all bearing surfaces properly. For high-performance or older engines, consider upgrading to synthetic oil, which offers better protection against heat and breakdown.

Maintaining proper oil pressure is crucial for bearing life. This means keeping your oil pump in good condition and addressing any leaks promptly. Similarly, keeping your cooling system in top shape prevents the engine from running too hot, which can break down oil faster and increase bearing wear.

How you drive also impacts bearing life. Avoid prolonged high-RPM operation before your engine is fully warmed up. Cold oil doesn’t flow as well and can leave bearings inadequately lubricated during those first critical minutes. Also, give your engine a chance to warm up before putting it under heavy load, especially in cold weather.

Finally, pay attention to your engine’s maintenance schedule beyond just oil changes. Air filters, fuel filters, and ignition components all affect how efficiently your engine runs. An engine that’s misfiring or running inefficiently puts additional stress on bearings and other components.

When to Replace vs. When to Rebuild

When facing rod bearing issues, you’ll eventually need to decide whether to replace just the bearings or opt for a complete engine rebuild or replacement. This decision depends on several factors, including the extent of the damage, the age of your engine, and your budget.

If you’ve caught the problem early – perhaps after hearing unusual noises or seeing warning signs during regular maintenance – a bearing replacement might be sufficient. This is relatively less expensive and makes sense for engines that are otherwise in good condition. However, if the bearings have already failed catastrophically, they’ve likely caused damage to the crankshaft, connecting rods, and possibly even the engine block.

The age and value of your equipment should factor into your decision. For newer, valuable machinery, investing in proper repairs makes financial sense. For older equipment with multiple issues, a complete rebuild or even replacement might be more cost-effective in the long run. Sometimes, the labor cost to access and replace bearings can be so significant that the additional cost to address other wear items at the same time makes economic sense.

Consider the downtime factor as well. A simple bearing replacement might have your equipment back in service within days, while a complete rebuild could take weeks. If you rely on the equipment for your business or critical operations, the cost of extended downtime might justify a quicker solution, even if it’s more expensive initially.

High-Performance Considerations for Rod Bearings

If you’re running high-performance equipment or have modified your engine for increased power, standard rod bearings might not be up to the task. High-performance engines create more heat and stress on bearings, requiring special considerations to prevent failures.

Performance-grade bearings often use stronger materials like copper-lead alloys, tri-metal constructions, or even coatings like polymer or diamond-like carbon (DLC) to withstand increased loads. These specialized bearings can handle higher temperatures and pressures without breaking down, but they come at a premium price that’s well worth it for modified engines.

Bearing clearance becomes even more critical in performance applications. While standard engines have manufacturer-specified clearances, performance engines might need slightly looser clearances to ensure adequate oil flow at high RPMs. However, this is a delicate balance – too much clearance creates excessive noise and reduces oil pressure. This is where working with an experienced performance engine builder pays dividends.

Oil selection deserves special attention in high-performance applications. Standard mineral oils may break down under the extreme heat and stress of performance driving. High-quality synthetic oils with robust additive packages designed for racing or high-performance use provide better protection. Some serious performance enthusiasts even add oil analysis to their regular maintenance routine to catch bearing wear before it becomes problematic.

Finally, consider upgrading connecting rods and other rotating assembly components when building for performance. Stronger rods flex less under load, reducing bearing stress. Similarly, a properly balanced rotating assembly minimizes vibration and bearing wear, extending engine life even under high-performance conditions.

FAQs About Rod Bearing Failure

How long can you drive with a rod knock?

Frankly, you shouldn’t drive at all with a rod knock. Once you hear that distinctive knocking sound, your bearings are already significantly damaged. Continuing to drive can lead to catastrophic failure within minutes or hours, potentially causing thousands in additional damage. If you hear a rod knock, shut the engine off and have the vehicle towed to a repair facility.

What causes rod bearings to fail prematurely?

Premature rod bearing failure usually stems from four main causes: inadequate lubrication (from low oil levels, poor oil quality, or oil pump issues), contamination in the oil, improper installation or manufacturing defects, and excessive engine loads or RPMs. Regular maintenance and proper driving habits can prevent most of these issues.

How much does it cost to replace rod bearings?

Replacing rod bearings typically costs between $900 and $4,000, depending on your engine type and the extent of damage. The parts themselves are relatively inexpensive ($50-300), but the labor is intensive because it requires partial engine disassembly. If the crankshaft or connecting rods are damaged, costs increase significantly.

Can regular oil changes prevent rod bearing failure?

Yes! Regular oil changes are the single most effective way to prevent rod bearing failure. Fresh oil provides proper lubrication and removes contaminants that can damage bearings. Following manufacturer-recommended oil change intervals (or more frequently under severe conditions) can dramatically extend bearing life and prevent expensive engine repairs.

What’s the difference between main bearings and rod bearings?

While both support the crankshaft, they serve different functions. Main bearings support the crankshaft in the engine block and handle the vertical loads of the pistons and rods. Rod bearings connect the crankshaft to the connecting rods and handle the rotational forces that turn linear piston motion into rotational motion. Both are critical, but rod bearings typically experience more stress and fail more commonly.

Keep Your Engine Running Smoothly with Quality Parts

Rod bearing failure can be devastating to your engine and your wallet, but with proper maintenance and quick action when warning signs appear, you can avoid the worst outcomes. Remember that quality parts make all the difference when it comes to reliability and longevity.

At FridayParts, we understand how important reliable components are for your equipment. That’s why we offer high-quality engine parts that meet or exceed OEM specifications at competitive prices. Whether you’re performing preventive maintenance or addressing a developing issue, using quality parts is always the most economical choice in the long run.

Don’t wait until you hear that dreaded knock. Implement a regular maintenance schedule, pay attention to warning signs, and use quality replacement parts to keep your equipment running smoothly for years to come. Your engine – and your budget – will thank you.

If you’re looking for specific engine components or have questions about rod bearings for your equipment, our team at FridayParts is here to help. With over 70,000 top-notch OEM-quality aftermarket parts and warehouses across the United States, Canada, Germany, and China, we can get you the parts you need quickly and at a fair price.