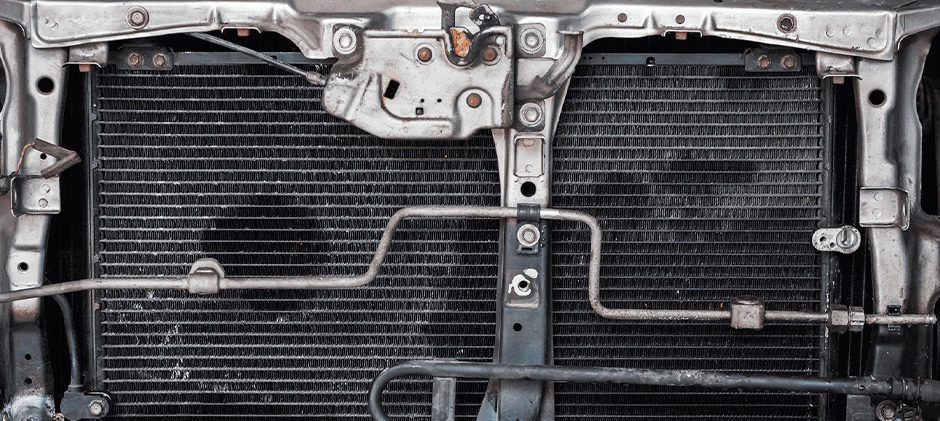

Heard from some operators who experienced the radiator explosion, so very worried about it? Don’t be. In fact, it’s not an explosion but a burst or crack, which was caused by overpressure. As long as you follow this guide to learn the reasons and prevention methods for the radiator, you can easily prevent this sad thing from happening. Also, we prepared the dealing methods if this unfortunately occurs.

5 Reasons Why a Radiator Explosion

To be specific, it’s not a bomb-like explosion, but a burst or rupture under extreme pressure, which causes the radiator’s seams to split or its plastic tanks to crack, forcefully spraying scalding hot coolant and steam.

1. A Failed Radiator Cap: The Safety Valve Fails

The radiator cap is the system’s most critical safety device. It’s designed to hold pressure to a specific level (typically 14-16 PSI), which allows the coolant to reach higher temperatures without boiling. If pressure exceeds this limit, the cap’s spring-loaded valve opens, venting excess coolant to the overflow tank. However, if the cap fails in the stuck-closed position, there is no other pressure release. Pressure from thermal expansion will build until the weakest point in the system—often a hose or the radiator itself—ruptures.

2. A Blown Head Gasket

This is a primary cause of rapid over-pressurization. A failed head gasket allows ultra-high-pressure combustion gases from the engine’s cylinders to be forced directly into the cooling system. This pressure spike is far too great for the radiator cap to handle, leading to a sudden and violent radiator failure.

3. A Clogged Cooling System

Off-road machinery operates in dusty, dirty environments. Over time, rust, sediment, and job-site debris can accumulate inside the narrow tubes of the radiator, creating a blockage. This clog restricts coolant flow, causing heat and pressure to build up behind it until something gives way.

4. A Faulty Thermostat

The thermostat regulates the engine’s temperature by controlling coolant flow. If it gets stuck in the closed position, coolant cannot circulate from the engine to the radiator. The engine will rapidly overheat, causing the trapped coolant to boil and create immense steam pressure that can easily burst hoses or the radiator itself.

5. Other Critical System Failures

The following failures are the direct cause of engine overheating, which is the prerequisite for the dangerous pressure buildup:

- Broken Fan Belt: Without the fan belt, the water pump doesn’t circulate coolant, and the fan doesn’t pull air through the radiator.

- Leaking Hoses: A broken or leaking radiator hose will cause a rapid loss of coolant, leading to overheating.

- Failing Water Pump: The first sign is often a noisy bearing. When the pump fails, coolant stops circulating.

Quick Diagnostic Guide:

| Cause | Key Symptom | Solution |

|---|---|---|

| Failed Cap | Rock-hard hoses | Replace cap |

| Blown Gasket | Bubbles in coolant | Major repair |

| Clogged System | Radiator cold spots | Flush system |

| Stuck Thermostat | Uneven hose temps | Replace thermostat |

| Other Failure | Visible/audible damage | Replace the failed part |

What to Do If You Encounter a Radiator Explosion?

If you see a massive cloud of steam or the temperature gauge shoots into the red, stay calm and follow these steps immediately:

- Shut Down the Machine Immediately. Find a safe, level spot and turn off the engine. This is your best chance to prevent a warped cylinder head or a seized engine.

- DO NOT OPEN THE RADIATOR CAP. This is the most important safety rule. The system is full of fluid and steam over 100°C (212°F). Opening it will cause a violent eruption and severe burns.

- Let It Cool Down Completely. Do not touch anything under the hood for at least an hour, or until the engine is cool to the touch.

- Call for Professional Service. A burst radiator means you must fix the underlying root cause. This requires a comprehensive diagnosis by a qualified technician.

How to Prevent a Radiator from Exploding?

Preventive maintenance is the best investment you can make to avoid downtime. These preventative steps are crucial year-round, but for a more detailed checklist specifically for peak season, review these must-know radiator maintenance tips.

- Keep Radiator Fins Clean: Regularly use compressed air to clear dust, mud, and debris from the radiator fins to ensure proper airflow.

- Perform Regular Coolant Flushes: Need to follow the manufacturer’s service interval to do a coolant flush and refill with high-quality liquid cooling, then you can avoid rust and blocking.

- Inspect Hoses and Clamps: When doing a daily walking-around check, must see the radiator hose got bulges, cracks, or softening. If the hose bulges, then obviously, the pressure is too much.

- Replace the Radiator Cap: This is one of the cheapest and most effective pieces of preventative maintenance. Replace the cap every few years to ensure its safety valve functions correctly.

- Be Prepared: For field operations, always carry a basic toolkit, a spare fan belt, essential hoses, clamps, and extra water or coolant.

What If Your Radiator Hasn’t Exploded But is Leaking?

A coolant leak is a critical warning sign. The moment you notice an issue, you should investigate. Look for these early warning signs:

- Temperature Gauge Running Hotter Than Normal: This is the best indicator that something bad is about to happen.

- Visible Coolant Leaks: When the machine stops, put there, need to look the ground has not bright color liquid water stay like a small pond.

- Corroded or Missing Cooling Fins: If cooling fins have already become bad or are gone, then the radiator cannot do good cooling, also its strong body structure is already damaged.

- Noisy Water Pump: A grinding or whining noise from the engine area can indicate failing water pump bearings, a precursor to overheating. Recognizing the 10 warning signs of water pump failure early can prevent a catastrophic overheating.

Treat any leak as an urgent call for a professional inspection to find and fix the problem before it leads to catastrophic failure.

FridayParts Service & Replacement Parts

Keeping your equipment in its optimal condition is vital to your working efficiency and personal safety. Now you’ve learned why the radiator explosion happens, how to deal with it, and how to prevent it.

The radiator explosion causes downtime, and the downtime leads to financial loss. So, knowing when a radiator in off-road machinery should be replaced and choosing a reliable radiator is necessary. FridayParts offers quality radiators that meet or exceed OEM quality. Made from durable materials, we guarantee the service life and stability of our radiators, which can prevent explosions to the greatest extent.

If you have any questions, feel free to contact our expert team. Your email will be replied to within 24 working hours. Explore now!