When an off-road machine feels “weak,” slow, or inconsistent, the root cause is often hydraulic flow and pressure—not the cylinder or motor you’re staring at. The hard part is choosing the right pump type so we don’t waste money, chase repeat failures, or end up with a system that never hits spec. In this guide, we’ll compare piston pump vs gear pump practically—how they work, where each one fits on heavy equipment, and how we can decide what to buy and stock.

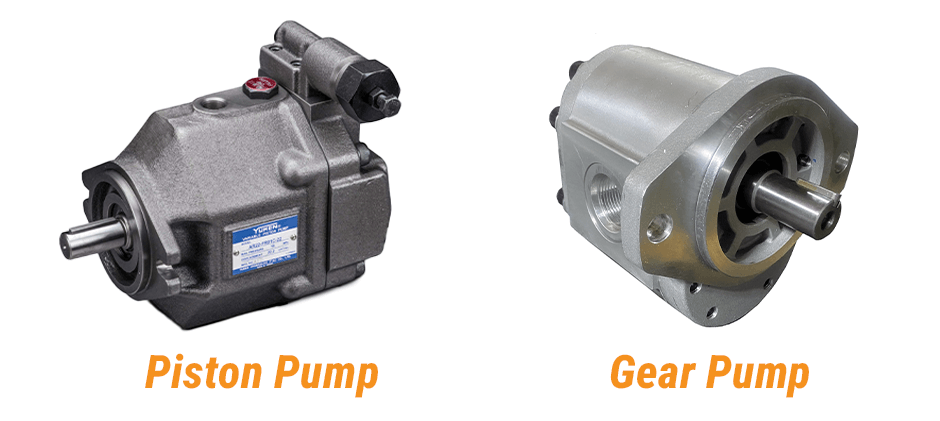

What are Piston Pumps and Gear Pumps?

Both piston pumps and gear pumps are positive-displacement pumps. That means each rotation (or cycle) moves a measured amount of hydraulic oil, so flow is predictable as long as internal leakage is under control. The difference is the pumping element and what that means for pressure, efficiency, and control.

What is a piston pump?

A hydraulic piston pump uses multiple pistons moving in cylinders to pull oil in and push it out under pressure. In mobile equipment, piston pumps are commonly used where we need higher pressure, better efficiency, and often variable displacement (flow changes without wasting energy as heat).

Common places we see piston pumps on off-road machinery:

- Mainly implement circuits that demand high pressure and responsive control

- Hydrostatic drive systems (where tight control and efficiency matter)

- Equipment that frequently changes load and needs stable performance

Typical designs you’ll hear about:

- Axial piston pumps (very common on mobile equipment)

- Variable displacement vs fixed displacement piston pumps

What piston pumps are good at

- Holding efficiency across a wider operating range

- Delivering high pressure without “feeling soft” under load

- Matching flow to demand (variable displacement), which can reduce heat and fuel use

Trade-offs

- More complex internals

- Higher part cost

- More sensitive to contamination and oil condition (cleanliness matters)

What is a gear pump?

A hydraulic gear pump moves oil using meshing gears. As the gears rotate, they trap fluid and carry it from the inlet to the outlet. Many mobile gear pumps are fixed displacement, meaning flow is primarily tied to RPM (and whatever bypass/valving the system uses).

From the FridayParts page content, gear pumps are positioned as the “workhorse” option for many off-road machinery systems, and they also supply specialized variants like:

- Pilot gear pump (for control systems and pilot-operated devices)

- Hydraulic gear pump (constant flow, robust design)

- Transmission charging pump (feeds transmission/hydrostatic charge needs)

Where we commonly see gear pumps on off-road machines:

- Pilot circuits (steady, reliable control oil)

- Steering, fan, auxiliary, or charge functions, depending on machine layout

- Systems that prioritize simplicity and a predictable fixed flow

What gear pumps are good at

- Simplicity and durability when maintained

- Predictable fixed flow for steady functions

- Often lower total cost vs piston pumps for similar flow class

- Easier “swap and go” replacement in many applications

Trade-offs

- Usually less efficient at higher pressures and across wide duty cycles

- Fixed displacement means flow control often relies on valves (which can add heat)

- Not always the best fit for high-demand, high-pressure main implement work

FridayParts also highlights usage considerations we should take seriously on both types:

- Proper installation (correct fittings/hoses to prevent leaks and pressure drops)

- Fluid compatibility (right oil to protect seals/internal parts)

- Regular maintenance (filters/fluids to prevent premature failure)

Key Differences Between Piston Pumps & Gear Pumps

This is the section that decides our purchase. Instead of general statements, we’ll tie each difference to what it changes on an off-road machine: cycle time, heat, fuel use, and how often we end up troubleshooting.

1) Mechanism and internal leakage behavior

- Piston pump: pistons + valve plate/swashplate design. More sealing surfaces and tighter tolerances. When wear starts, performance drops can show up as heat, slow functions, or pressure instability.

- Gear pump: meshing gears with close clearances. Wear usually shows up as reduced flow/pressure at operating temperature.

What we feel in the cab:

Piston pumps often keep performance more consistent across changing loads. Gear pumps feel “fine” until wear or demand pushes them outside their comfort zone.

2) Pressure capability and efficiency under load

In heavy equipment, pressure is where the differences become expensive.

- Piston pump: commonly selected for higher-pressure applications and for circuits where efficiency matters under continuous load.

- Gear pump: commonly used where pressure demands are moderate and steady.

Why this matters:

If we run a pump near its limit, oil temperature climbs, seals age faster, and valves start acting up. The “wrong pump” can turn into chronic overheating, not just low power.

3) Flow control: variable vs fixed displacement

- Many piston pumps are variable displacement, allowing the pump to reduce flow when demand is low—often improving fuel efficiency and reducing heat.

- Gear pumps are typically fixed displacement. To control actuator speed, the system often dumps excess flow across valves, which can generate heat during long, low-speed operations.

Rule of thumb we can use:

If our machine spends a lot of time feathering functions or operating at partial demand, variable displacement can pay back in lower heat and smoother control.

4) Sensitivity to contamination and oil quality

Both pump types hate dirty oil, but the penalty is often different.

- Piston pump: tighter tolerances tend to mean higher sensitivity to contamination. Clean filtration and correct oil matter more.

- Gear pump: generally more forgiving, but still vulnerable—especially if cavitation occurs or debris scores the housing.

If our maintenance environment is rough (dust, rushed filter changes, mixed oil), a gear pump may survive abuse better—but we should fix the process, not rely on forgiveness.

5) Noise, feel, and low-speed performance

- Gear pumps can be smooth and predictable for steady circuits, but noise and vibration vary by design and wear.

- Piston pumps can deliver excellent controllability, especially in systems designed for load-sensing/variable displacement.

What matters most is matching the pump to the system architecture (open center vs closed center, load-sensing, etc.). A great pump in the wrong circuit still performs poorly.

6) Cost, serviceability, and replacement strategy

- Gear pump: often has a lower upfront cost, simpler replacement in many machine layouts.

- Piston pump: higher cost, but can be the more economical choice when efficiency and high-pressure performance reduce heat-related failures and downtime.

Summary table: piston vs gear

| Category | Piston pump | Gear pump |

|---|---|---|

| Displacement | Fixed or variable (common) | Usually fixed |

| Best fit | High pressure, changing loads, efficiency-focused systems | Steady flow circuits, simpler hydraulic layouts |

| Efficiency at high load | Typically higher | Typically lower as pressure rises |

| Heat generation risk | Often lower when properly matched (especially variable displacement) | Can be higher if excess flow is throttled |

| Complexity | Higher | Lower |

| Contamination sensitivity | Higher (generally) | Moderate (generally) |

| Typical use on off-road machinery | Main implement, hydrostatic/advanced systems | Pilot, charge, auxiliary, steady-flow functions |

Do You Need a Piston Pump or a Gear Pump?

Now we make the decision the way we’d do it in a shop: by matching pump type to the machine’s job, circuit design, and failure symptoms.

Step 1: Identify the circuit role (main power vs support power)

Ask where the pump sits and what it feeds:

- If the pump runs main implements under high load (boom/arm functions, continuous heavy hydraulic demand), we often need a piston pump—especially if the system is designed for variable displacement or load-sensing.

- If the pump feeds pilot controls, charging, or a steady auxiliary function, a gear pump is frequently the correct and cost-effective choice.

FridayParts explicitly lists pilot gear pump, hydraulic gear pump, and transmission charging pump types for off-road machinery, which is a helpful way to think about job roles.

Step 2: Use symptoms to avoid buying the wrong pump

Here are field symptoms and what they often point to (not a guarantee, but a strong starting point):

Symptoms that often push us toward a piston pump (or piston pump diagnosis):

- The machine runs okay cold, but slows badly hot under load

- Frequent overheating during heavy, continuous work

- Need for smoother speed control across changing loads

- System designed for variable displacement/load-sensing (a gear pump won’t “act like” one)

Symptoms that often fit a gear pump replacement scenario:

- A simple circuit with steady demand has lost speed/force

- Pilot functions feel weak or inconsistent

- Charging/auxiliary flow is low, but the main system is otherwise normal

- We want a durable, straightforward pump for a fixed-flow requirement

Step 3: Check compatibility details before we order

This is where most wasted time happens. Before we buy either type, we should confirm:

- Mounting pattern and shaft type

- Port sizes and orientation

- Rotation direction

- Displacement (cc/rev) and target flow at operating RPM

- Pressure rating needed by the system

- For tandem setups: stage sizes and section order

If we’ve confirmed the machine’s requirements and we’re replacing a fixed-flow unit, browsing a dedicated heavy-equipment gear pump catalog can be faster than searching generic pump listings, because the selection is organized around off-road machinery applications and common replacement patterns.

Step 4: Decide based on operating cost, not just part price

This is the “owner” view:

- If downtime is expensive and the machine lives at high load, a piston pump often wins because efficiency reduces heat and preserves system components.

- If the job is steady, moderate, and the circuit doesn’t need variable displacement, a gear pump can be the smarter choice because it’s simpler and more affordable.

If we’ve decided a gear pump fits our circuit (pilot/charge/steady flow), it’s worth buying from a supplier that covers multiple off-road equipment categories and offers clear fitment guidance. FridayParts positions itself that way—aftermarket supply, wide compatibility, and inventory breadth across many heavy equipment lines—so when we need a replacement gear pump, we can source the correct type (pilot, hydraulic, or transmission charging) without turning the purchase into a research project.

Conclusion

A piston pump is usually the better fit when we need high pressure, efficient performance under changing loads, and (often) variable displacement. A gear pump is a solid choice for steady-flow roles like pilot, charge, or simpler hydraulic circuits where durability and cost matter. If we match the pump to the circuit and keep oil/filtration in shape, we cut heat, downtime, and repeat failures. For reliable aftermarket options, FridayParts offers affordable, high-quality pumps with wide heavy-equipment compatibility.