A water pump plays a crucial role in circulating coolant through an engine’s cooling system, thereby preventing overheating. A failing water pump can lead to costly downtime and repairs. If you own off-road machinery, you’ve probably noticed a water pump leak—your first warning of trouble. This comprehensive guide explains why water pump leaks occur, how to identify and repair them, and more. By following this guide, you’ll know how to keep your equipment running smoothly.

What Causes a Water Pump to Leak?

Although a water pump is a sturdy component, it works under constant stress. Leaks usually start from the failure of one of its key parts. Knowing the cause can help you avoid future problems.

1. Worn Shaft Seal

This is the most common cause. The water pump has an internal shaft that spins the impeller. A dynamic seal prevents coolant from leaking along this spinning shaft. Over many hours of operation, the load from the drive belt, engine vibrations, and hot coolant wear down this seal. When the seal fails, coolant begins to seep out, often through a “weep hole,’ which is there to signal seal failure.

2. Corrosion and Contamination

The quality of your coolant is very important. Using the wrong coolant type, mixing different types, or using water alone can cause rust and corrosion within the cooling system. These particles act like sandpaper, damaging the delicate seals and impeller.

3. Impeller Damage

The impeller, which pushes coolant through the engine, can be damaged by corrosion or cavitation. Cavitation happens when low pressure creates vapor bubbles in the coolant. When these bubbles collapse, they forcefully erode the impeller’s surface. A damaged or unbalanced impeller can cause vibrations that speed up wear on the shaft bearing and seal, eventually leading to a leak.

4. Incorrect Installation or Maintenance

Human error can also cause early failures.

- Incorrect Belt Tension: If the drive belt is too tight, it puts excessive sideways force on the water pump’s shaft and bearing. This overloads the bearing and causes it to fail early, taking the seal with it.

- Excessive Sealant: Some mechanics add extra sealant ‘just in case’ when installing a pump with a gasket. But too much sealant can be harmful. It can squeeze into the cooling system, break off, clog the radiator, or damage the new pump’s seal.

5. Age and Wear

Like any mechanical part, water pumps have a limited lifespan. Their bearings, seals, and housing undergo constant thermal cycles and vibrations. So after years of use, they will simply wear out.

Will a Faulty Water Pump Leak When the Engine Is Off?

In some equipment, the water pump will stop leaking once the engine cools down, and will start leaking again once the engine reaches its operating temperature.

Intermittent leaks are often a sign of wear and seal failure in the water pump. Ensure that a trained professional inspects your machinery as soon as you notice signs of intermittent coolant leaks.

Water Pump Leak Consequences

A small coolant leak may not seem like a significant issue, but in heavy machinery, it can lead to serious problems. The impact of a water pump failure goes well beyond the cost of the pump.

The main risk is engine overheating. When the coolant flow stops, the engine temperature quickly rises. This can cause:

- Warped Cylinder Heads: Aluminum heads can warp due to extreme heat, compromising the seal between the head and the engine block.

- Blown Head Gaskets: Overheating is the leading cause of head gasket failure.

- Damaged Pistons and Cylinders: Excessive heat can cause pistons to expand and seize within cylinders, resulting in severe engine damage.

Beyond engine damage, a failing pump can cause collateral harm. Leaking coolant can spray onto belts, making them slip and wear out. Most critically, a machine failure results in costly downtime. Every hour your equipment is offline means money lost.

How to Stop the Water Pump Leak?

When you find a leak, you have two options: a temporary fix or a permanent repair.

For heavy-duty commercial equipment, we strongly recommend against temporary solutions like coolant leak sealant additives. While these might fix a small leak in a passenger car, they are not reliable for demanding engines. The risk of sealant clogging the radiator or engine passages is too high. A temporary patch that fails under load can leave you with the same problem, but potentially worse.

The best and most reliable solution is to replace the faulty water pump. This fixes the issue at its source and restores the cooling system’s functionality, keeping your equipment dependable.

Steps to Replace Your Leaking Water Pump

Replacing a water pump requires mechanical skill, but it is easy if you follow the correct steps. The exact steps can vary based on your equipment’s make and model, but here is a general guide.

1. Safety First

Make sure the engine is completely cool and disconnect the battery to prevent accidental starting.

2. Drain the Coolant

Place a large drain pan under the radiator. Then, open the radiator’s petcock valve or loosen the lower radiator hose to drain the entire cooling system.

3. Gain Access

This is often the most challenging part. You may need to remove the fan, fan shroud, drive belts, and possibly other accessories or covers to reach the water pump.

4. Remove the Old Pump

Carefully loosen and take out the bolts holding the water pump to the engine block. Note the length and position of each bolt. Gently tap the pump with a rubber mallet if it’s stuck.

5. Clean the Mating Surface

This step is critical for a leak-free seal. Use a gasket scraper and a wire brush to remove all traces of the old gasket and any sealant from the engine block. The surface must be clean and smooth.

6. Install the New Pump

Compare the new pump to the old one to ensure it’s the right part. Apply the new gasket to the pump (use sealant only if the manufacturer’s instructions call for it). Carefully position the new pump and hand-tighten the mounting bolts.

7. Torque to Specs

Use a torque wrench to tighten the bolts in a crisscross pattern to the manufacturer’s recommended torque. This ensures even pressure on the gasket.

8. Reassemble

Reinstall all the components you removed in reverse order. Pay close attention to the drive belt tension—it should be snug but not too tight.

9. Refill and Bleed the System

Close the radiator drain. Refill the system with the coolant recommended by the manufacturer. Start the engine with the radiator cap off to let air escape. You may see bubbles; keep adding coolant until the level stabilizes.

10. Final Check

Once the engine heats up, install the radiator cap and carefully check for leaks around the new pump and hoses.

Don’t be scared by these ten steps. It looks complex, but easy to do because it’s specific and detailed. Most people can finish it personally.

How to Prevent the Water Pump Leak?

If you’re looking to stop the leak from occurring again and again, here are some basic steps to follow:

- Flush the cooling system to remove and clear all the debris that might have accumulated.

- Drain the coolant from the system to prevent spills. You can use a drain pan to collect the coolant.

- Loosen or remove the engine belt that is connected to the pump

- Try replacing the components, such as hoses and pulleys.

- Check the gasket or O-ring and replace it if it looks worn out.

- Refill the cooling system with a new coolant.

- Install a new pump

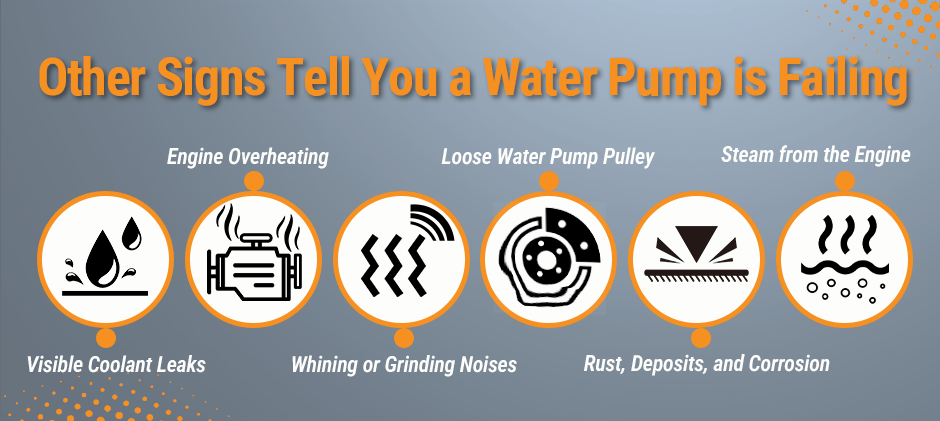

Other Signs Tell You a Water Pump is Failing

Besides the water pump leak, many other signs tell you the water pump has issues. Catching a failing water pump early can save you from a costly repair. Watch out for these clear warning signs.

- Visible Coolant Leaks: You may find a puddle of coolant, which is usually green, orange, or red and has a sweet smell, on the ground under the front of the engine. Trace the leak to its source. A leak from the pump’s weep hole or a gasket seam is a definite sign of failure.

- Engine Overheating: If the water pump starts to fail, it can’t circulate coolant properly. The engine’s temperature will rise, and the temperature gauge on your dashboard will enter the red zone.

- Whining or Grinding Noises: A high-pitched whining that varies with engine RPM often indicates a loose drive belt or a failing bearing inside the water pump. As the bearing wears out, it can also cause a grinding or groaning noise. Don’t ignore these sounds—they are the pump’s way of signaling trouble.

- Loose Water Pump Pulley: If you can safely access the pump (with the engine off), try to wiggle the pulley. Any side-to-side or in-and-out movement suggests the internal bearing is damaged. The entire unit should then be replaced.

- Rust, Deposits, and Corrosion: A visual inspection of the pump’s exterior can reveal a lot. Significant rust, crusty deposits around the weep hole, or pitting on the housing indicate advanced corrosion, implying the internal parts are in worse shape.

- Steam from the Engine: If you see steam or smoke coming from under the hood, it’s a sign that leaking coolant is hitting hot engine parts and vaporizing. This indicates a serious leak and a severely overheating engine.

Conclusion

A water pump leak on your off-road machinery is a serious warning that should never be ignored. As a result, by knowing the causes, recognizing the symptoms early, and committing to a proper replacement, you can protect your investment and keep your equipment in its optimal condition.

Don’t let a faulty water pump compromise your operations. Get the right part quickly to minimize downtime and keep your projects on track. Explore our selection at FridayParts.com today.