In today’s video, our hosts Caleb and Tristan Ziggler dive into an essential part of agricultural machinery: the turbocharger. As we gear up for the spring planting season, it’s crucial to ensure our equipment is in peak condition. In this video, our two professional hosts cover valuable tips on maintaining, inspecting, and repairing your turbocharger, ensuring your machine runs smoothly all season long. The blog covers almost everything you need to know about the turbocharger, from what it is to how to replace a turbocharger. If you find it helpful, don’t forget to share it with the ones who might need it. Follow the FridayPart blog for more information!

Explore More Types of Turbocharger

Understanding Turbo

Before delving into maintenance, it’s important to understand how a turbocharger works. A turbocharger harnesses exhaust gas to spin a turbine that compresses intake air. This process boosts engine horsepower and efficiency. The key components of a turbocharger include the turbine, compressor, and intercooler. While this tractor model doesn’t have an intercooler, newer models do. Understanding these components helps you identify what to look for during maintenance and ensures that you catch any potential issues early.

How to Maintain and Inspect Turbo

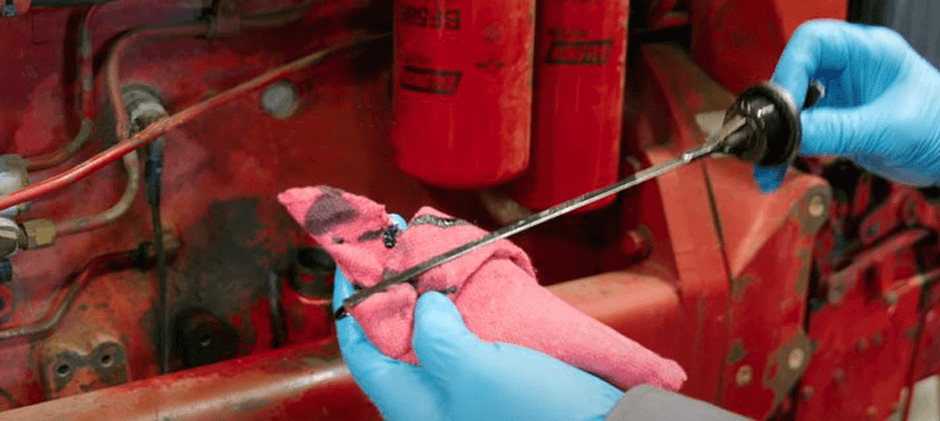

1. Inspect Engine Oil

Regular maintenance is crucial for extending the life of your turbocharger. Start with inspecting the engine oil. When you pull out the dipstick, check for any contaminants, even after an oil change. The presence of metal filings, especially on the magnetic oil plug, can signal a problem with the engine or turbo. This is an indicator that it’s time to inspect further.

2. Choose the Right Oil & Oil Filters

The grade of oil you use is important for your tractor’s longevity. For older diesel tractors, 15W40 oil is recommended. Clean oil, combined with proper filters, plays a key role in maintaining engine health. Ensure that both the primary and secondary oil filters are in good condition. It’s also vital to keep your air filter clean. A clogged filter reduces airflow to the turbocharger and could lead to its failure.

3. Check Intake Pipe, Air Couplers & Lubricant

Check the intake pipe and air couplers for cracks or signs of excessive wear. On the intake side, ensure the silicone coupler is securely in place. You also want to inspect the oiling system that lubricates the turbine’s spline. If oil doesn’t properly lubricate the turbo, it will seize up and fail. If you notice oil leakage around the turbo or hear noise from it, it’s a sign that the turbo might need replacing.

4. Check Wastegate

If your tractor is a newer model, check the wastegate and ensure its actuator opens and closes smoothly. A malfunctioning wastegate will affect your turbo’s performance, so inspect the linkage for any issues.

Common Turbo Problems & Troubleshooting

Turbochargers play a crucial role in boosting engine performance, but like any mechanical component, they can develop issues over time. Recognizing the signs of turbo failure early can save you from costly repairs and downtime. Here are some common turbo problems and how to troubleshoot them:

- Loss of Power – If your tractor or machinery experiences a sudden drop in power, check for boost leaks in hoses, intercooler connections, or intake pipes. A hissing sound often indicates an air leak, which reduces turbo efficiency.

- Excessive Smoke – Blue or black smoke from the exhaust may signal oil leakage into the combustion chamber. This could be due to worn turbo seals or issues with the oil supply line. Inspect these components and replace them if necessary.

- Unusual Noises – Grinding or squealing sounds from the turbo indicate internal damage, often caused by debris in the housing or shaft misalignment. Check for loose parts and ensure there is no excessive play in the shaft.

- Check Engine Light – A turbo-related issue can trigger the check engine light, often pointing to a boost pressure problem. Using a diagnostic tool to read the fault codes can help pinpoint the exact issue and guide necessary repairs.

- Oil Contamination or Leaks – A turbo relies on a steady flow of clean oil for lubrication. Contaminated or low oil levels can lead to bearing failure, causing the turbo to seize. Always use the recommended oil grade and inspect for leaks in oil supply and return lines.

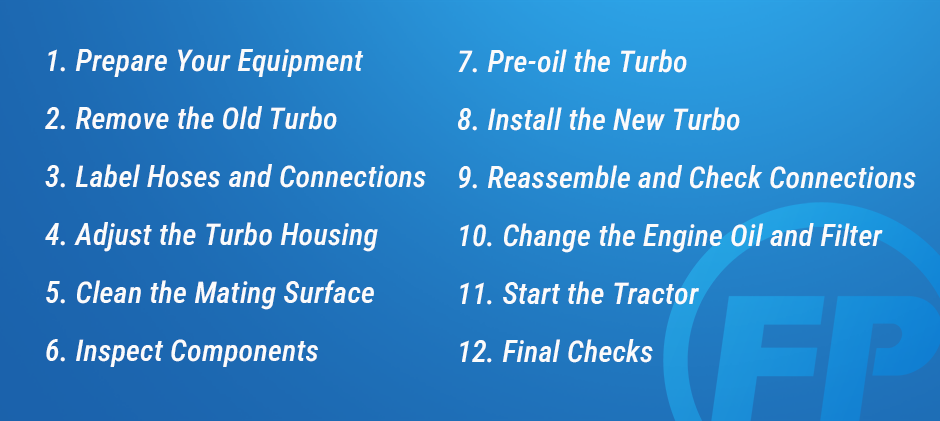

How to Replace a Turbocharger? Step-by-Step Guide!

Sometimes, despite regular maintenance, you’ll need to replace your turbocharger. This could be due to severe wear, a complete failure, or simply wanting to upgrade to a more powerful turbo for increased horsepower. You may ask, is it easy to replace a turbocharger? Can I change a turbo myself? The answers are not as difficult as you might think, and yes. Here’s a step-by-step guide for replacing your turbo:

1. Prepare Your Equipment

Before you begin, ensure you have the necessary safety equipment. Always prioritize safety when working on machinery.

2. Remove the Old Turbo

Start by removing the intake and exhaust pipes. Look out for any damaged couplers, which will need to be replaced. Don’t forget to replace the turbo manifold gasket and oil cooler line gasket—these are typically included with parts from suppliers like FridayParts.

3. Label Hoses and Connections

If you’re new to turbo replacement, labeling hoses and connections will help you reassemble the turbo correctly.

4. Adjust the Turbo Housing

Loosen the bolts on the turbo housing so you can adjust the angles. This ensures that everything lines up when you reconnect the hoses.

5. Clean the Mating Surface

Before installing the new turbo, clean the mating surface where the gasket will be placed. This ensures a tight seal and prevents leaks.

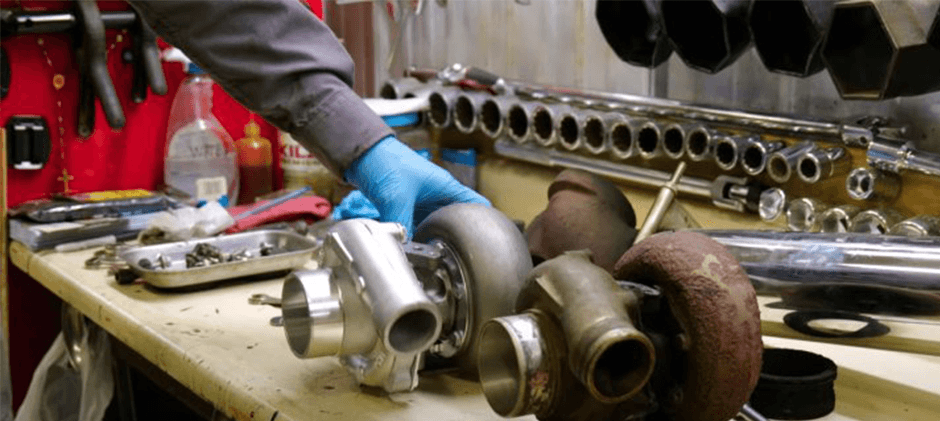

6. Inspect Components

While everything is apart, check other components such as the oil line and air intake system. If anything looks worn or damaged, replace it to avoid future problems.

7. Pre-oil the Turbo

Before installation, pre-oil the turbo by adding oil through the oil line and spinning the turbine. This ensures that it doesn’t start dry, which can lead to damage.

8. Install the New Turbo

When installing the new turbo, make sure to use the new gaskets provided. Torque all bolts according to the manufacturer’s specifications to prevent leaks.

9. Reassemble and Check Connections

Reattach the intake and exhaust pipes. Ensure all connections are tight, and that no lines are bent or pinched.

10. Change the Engine Oil and Filter

Before starting the tractor, change the engine oil and filter. Clean oil is vital for a long-lasting turbo.

11. Start the Tractor

To build oil pressure, disconnect the ignition and wait until you see the oil pressure build-up. Once it does, reconnect the ignition and start the tractor. Let it idle for a few minutes to ensure everything runs smoothly.

12. Final Checks

Look for any warning lights or unusual noises. If everything is running smoothly, you’ve successfully replaced the turbo!

Turbocharger FAQs

What is the Cost of Replacing Turbocharger?

The cost of replacing a turbocharger varies depending on the make and model of your vehicle or machinery. On average, a turbo replacement can cost anywhere from $1,000 to $3,500, including parts and labor. Aftermarket turbochargers tend to be more affordable than OEM replacements. If only specific components (like seals or bearings) need replacing, repair costs may be lower. Regular maintenance can help prevent expensive replacements.

But if you come to our store for turbo replacement, you can find only the most cost-effective solutions. We offer premium aftermarket turbos at unbeatable prices, ensuring you get top performance without breaking the bank. Don’t settle for overpriced options—shop at FridayParts and experience the perfect

Can I Still Drive My Car with a Bad Turbo?

Technically, you can, but it’s not recommended. A failing turbo reduces engine efficiency, leading to loss of power, excessive smoke, and increased fuel consumption. In severe cases, a damaged turbo can cause engine failure due to oil contamination or excessive heat buildup. If you suspect turbo issues, it’s best to address them immediately to prevent further damage.

Conclusion & Final Thoughts

Maintaining your turbocharger is crucial for keeping your equipment running efficiently. By following these maintenance and replacement steps, you can ensure that your turbo lasts longer and performs better. Regular checks and timely repairs will help you avoid costly issues down the line. If you’re unsure about any steps or the problem persists despite your efforts, consulting a professional is always a wise choice. They can provide expert advice and safe repairs. FridayParts has a wide inventory of turbochargers, aiming to provide the best replacement for your machinery. No matter what your equipment is, a tractor, loader, excavator, or any heavy equipment, we have you covered!

We hope this guide was helpful! If you have any questions, feel free to leave them in the comments below. Don’t forget to like the video and subscribe FridayParts YouTube channel for more helpful tips. If you find the article helpful, it would be a great honor for us if you share it with your friends in other social platforms! Subscribe to FridayParts.blog for more pro advice! Happy farming and we’ll see you next time!