When buying a hydraulic cylinder replacement, the best way is to determine which aftermarket cylinder is suitable for your machine based on the cylinder block model. However, if you are not sure about the model, the next step is to measure the hydraulic cylinder and find a suitable solution. If you are not familiar with this process, read on. In this article, we will outline the process step by step, including all the formulas you need to know.

Types of Hydraulic Cylinders

Before we grab our tools, it’s helpful to know what type of cylinder we’re working with, as this can influence its construction and mounting. On heavy machinery, you’ll typically encounter three main types:

-

Piston Rod Cylinders: The most common type, with a piston inside the cylinder barrel, is moved by hydraulic oil. They can be single-acting (powering in one direction) or double-acting (powering in the extension and retraction directions).

-

Plunger Cylinders: These cylinders do not use pistons. Instead, the rod itself acts as a plunger to drain the fluid. They are almost always single-acting, relying on gravity or load to retract, and are commonly found on equipment such as snowplows or simple lifts.

-

Telescopic Cylinders: contain layers of nested steel tubes that extend like a telescope, providing a very long stroke from a compact retracted length. They are common in dump trucks and other applications where long distances are required.

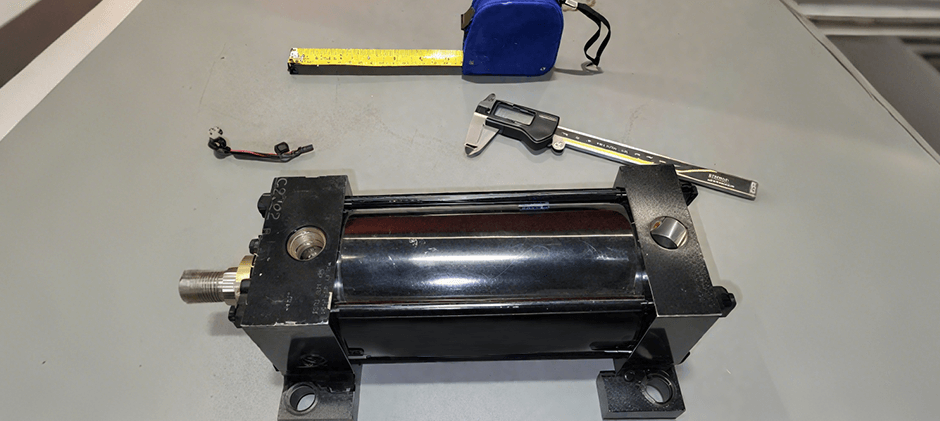

Preparations for Measuring a Hydraulic Cylinder

Proper preparation is key to measuring a hydraulic cylinder safely and efficiently. This means gathering the right tools and knowing exactly what attributes you need to measure.

Tools to Measure a Cylinder

For this job, precision is more important than speed. A simple tape measure won’t be enough for every dimension. We recommend having the following on hand:

-

Calipers: Essential for accurately measuring the rod diameter and potentially the bore.

-

Tape Measure: Best for measuring the longer dimensions, like retracted and extended lengths.

-

Thread Gauges: For correctly identifying the size and pitch of the hydraulic ports.

-

Safety Equipment: Always wear eye protection and safety-toed boots when working with heavy components.

The Main Hydraulic Cylinder Attributes

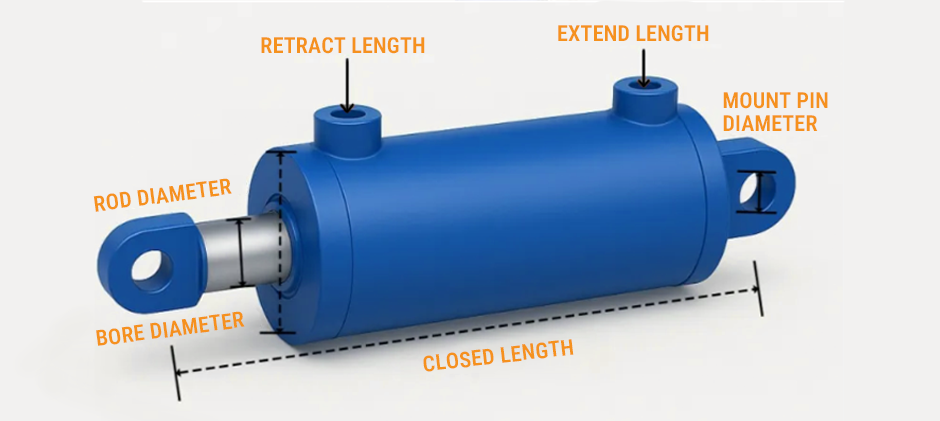

When you set out to measure a hydraulic cylinder, you are looking for a specific set of dimensions that define its size, travel, and how it connects to the machine. These are the critical numbers you’ll need:

-

Bore Diameter

-

Rod Diameter

-

Stroke

-

Retracted and Extended Lengths

-

Mounting Style and Dimensions

-

Port Size and Type

With our tools ready and our measurement list in hand, we can now begin the process.

Steps for Measuring a Hydraulic Cylinder

Step 1: Check for a Part Number

Before you measure anything, thoroughly inspect the cylinder barrel for a stamped or engraved part number or a manufacturer’s nameplate. This is the fastest and most accurate way to identify a replacement. If you find one, your search might be over. However, if it’s unreadable or missing, proceed to the next steps.

Step 2: Measure the Bore Diameter

The bore is the inside diameter (I.D.) of the cylinder barrel. This is a critical dimension that determines the cylinder’s force.

-

If Disassembled: Use inside calipers or a telescoping gauge to measure the inner wall of the barrel directly. This is the most accurate method.

-

If Assembled: This is trickier. You can measure the outside diameter (O.D.) of the barrel and subtract the wall thickness twice. However, wall thickness can vary, making this method less reliable. If possible, disassembling the cylinder to get a direct bore measurement is always best.

Step 3: Measure the Rod Diameter

Step 4: Measure the Retracted and Extended Lengths

These measurements define the working range of the cylinder.

- Retraction length: When the cylinder is completely closed, the distance from one mounting pin center to another is measured using a tape measure.

- Stretch length: When the cylinder is fully open, measure the same distance from the pin center to the pin center.

- Safety first: if the cylinder is still on the machine, follow all locking/listing procedures before measuring. If hydraulic pressure must be applied to extend the cylinder, be aware of the possibility of high-pressure fluid leakage.

Step 5: Calculate the Stroke

The stroke is the total distance the cylinder travels. It’s not a direct measurement but a simple calculation based on the previous step.

Formula: Stroke = Extended Length – Retracted Length

Step 6: Identify the Mounting Style

How the cylinder attaches to the machine is just as important as its size. A cylinder with the wrong mounts is useless. Common mounting styles on off-road equipment include:

-

Clevis Mounts: A U-shaped bracket with a pin hole.

-

Cross-Tube Mounts: A tube welded to the end of the cylinder with a pin hole through it.

-

Trunnion Mounts: Pins that protrude from the sides of the cylinder barrel, allowing it to pivot.

-

Flange Mounts: A flat plate that bolts onto a surface.

Measure the pin hole diameters, the width of the mounts, and any other relevant dimensions of your specific mounting type.

Step 7: Identify Port Size and Type

The hydraulic ports are where the hoses connect. You need to identify both their thread type and size.

-

Thread Type: The most common types are NPT (National Pipe Taper) and SAE (also known as O-Ring Boss or ORB). NPT threads are tapered, while SAE threads are straight and seal with an O-ring.

-

Size: Use a thread gauge and calipers to determine the thread pitch and diameter. If an adapter is used, be sure to measure the port on the cylinder itself, not the adapter.

Hydraulic Cylinder Formulas Chart

Understanding the relationship between pressure, area, and force can be helpful. Here are a few key formulas to keep in mind.

| Calculation | Formula | Variable Definitions |

|---|---|---|

| Cylinder Force (Push) | Force (lbs) = Piston Area (in²) x Pressure (PSI) | Piston Area = π x (Bore Diameter / 2)² |

| Cylinder Force (Pull) | Force (lbs) = (Piston Area – Rod Area) x Pressure (PSI) | Rod Area = π x (Rod Diameter / 2)² |

| Horsepower Required | HP = (Pressure (PSI) x Flow (GPM)) / 1714 | GPM = Gallons Per Minute |

| Inches to Millimeters | Millimeters = Inches x 25.4 | |

| Millimeters to Inches | Inches = Millimeters x 0.03937 |

Conclusion

To measure the replacement hydraulic cylinder, including the bore, piston rod, stroke, mounting method, and port details, you will handle the exact hydraulic cylinder information you need. For more than a decade, FridayParts has been offering high-quality products at affordable prices, compatible with a wide range of heavy equipment brands. If you need to replace the hydraulic cylinder or need help choosing the right one, please contact our team today to help you complete the repair with confidence.