If you’ve been wondering why your engine isn’t running as smoothly as it should, the answer might be hiding in those tiny numbers on your fuel injectors. Yep, we’re talking about injector trim codes – those mysterious sequences that can make a world of difference in how your engine performs.

At FridayParts, we’ve helped thousands of customers optimize their engines by properly using injector trim codes. In this guide, we’ll walk you through everything you need to know about finding and using these codes to get your engine running at its best.

What Are Injector Trim Codes and Why Do They Matter?

Injector trim codes are calibration values assigned to fuel injectors during manufacturing. Think of them as your injector’s unique fingerprint. These codes tell your engine’s computer (ECM) how much to adjust fuel delivery based on each injector’s specific flow characteristics.

Why should you care? Well, no two injectors are exactly alike – even from the same production batch. Some flow a little more fuel, others a little less. These tiny differences can add up to big problems: rough idling, poor acceleration, failed emissions tests, and wasted fuel.

When your engine’s computer knows these codes, it can make micro-adjustments to fuel delivery, ensuring each cylinder gets precisely the right amount of fuel. The result? Smoother operation, better fuel economy, lower emissions, and improved overall performance.

Imagine trying to pour the same amount of water through six different funnels – some might flow faster, others slower. Trim codes help your engine compensate for these differences, creating perfect balance across all cylinders.

How to Locate Injector Trim Codes on Different Engine Types?

Finding injector trim codes varies depending on your engine type and manufacturer. Here’s how to locate them on the most common engines:

-

Diesel Engines (Cummins, Detroit, CAT)

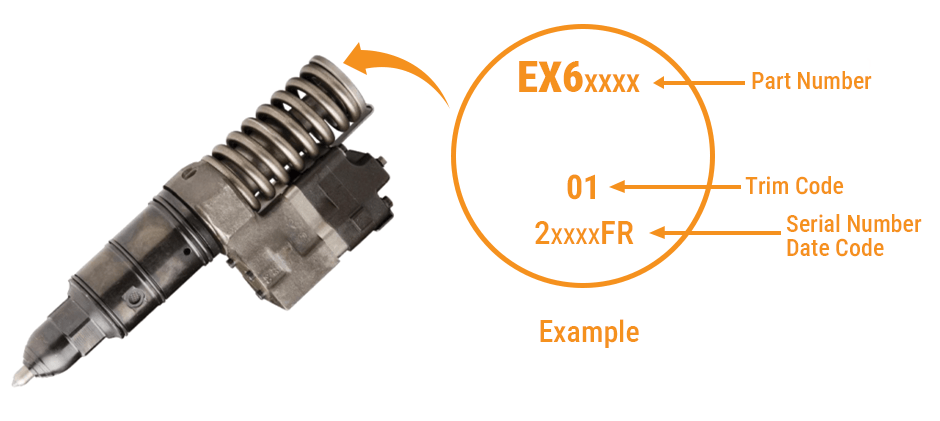

On most diesel engines, trim codes are printed directly on the injector body. Look for a series of numbers and letters, often preceded by a specific identifier like “TIC” (Trim Injector Code) or “IMA” (Injector Matching Authorization).

For Cummins engines, you’ll typically find a 6 or 7-character code stamped on the injector body. Detroit Diesel uses similar stamping methods, while CAT engines often have the codes on a small metal tag attached to the injector.

If you can’t see the codes because of grime or awkward positioning, you might need to remove the injector – but be careful! This is a job best done with the right tools and a bit of experience. If you’re not comfortable doing it yourself, any diesel mechanic should be able to help you out.

-

Gasoline Direct Injection (GDI) Engines

For modern GDI engines found in many passenger vehicles, trim codes are usually more high-tech. Instead of physical stamps, these values are often stored electronically and can be accessed through the vehicle’s OBD-II port using a scanner that supports injector programming.

Brands like Ford, GM, and Chrysler typically require dealer-level scan tools to access these codes, though some advanced aftermarket scanners can also retrieve this information.

-

Common Rail Injection Systems

On common rail systems (popular in modern diesel engines), look for a QR code or alphanumeric sequence on the injector body. These are often located near the electrical connector or on the side of the injector.

In some cases, particularly with Bosch injectors, you’ll find a 6 to 10-digit code that needs to be input into the engine’s ECM. These codes are crucial for proper operation in high-precision common rail systems.

Tools Needed to Read and Program Injector Trim Codes

Having the right tools makes all the difference when working with injector trim codes. Here’s what you’ll need:

Basic Tools for All Engines

- Good lighting (LED flashlight or work light)

- Magnifying glass (trim codes can be tiny!)

- Clean rags and brake cleaner (to clean injectors before reading codes)

- Camera or smartphone (to document codes before removal)

- Notebook (to record codes in case pictures aren’t clear)

Electronic Tools for Modern Engines

- OBD-II scanner with injector programming capabilities

- Laptop with manufacturer-specific software (for many newer vehicles)

- Injector code reader (specialized tool for certain diesel engines)

Advanced Tools for Professional Work

- Injector flow testing equipment (for verifying injector performance)

- Digital calipers (for measuring injector components when codes are worn)

- Specialized injector removal tools (engine-specific)

At FridayParts, we stock a range of tools designed specifically for working with injector systems. Having the right equipment not only makes the job easier but helps prevent damage to delicate injector components.

Pro tip: Before investing in expensive diagnostic equipment, check if your local auto parts store offers tool rental services. Many places will rent out professional-grade scanners at reasonable daily rates.

Step-by-Step Guide to Programming Injector Trim Codes

Now that you’ve found your trim codes, it’s time to put them to work. Here’s our step-by-step process for programming them into your vehicle’s ECM:

Step 1: Gather All Necessary Information

Before you start, make sure you have:

- All injector trim codes are clearly recorded

- Vehicle’s service manual or programming guide

- Fully charged battery (programming requires stable power)

- Appropriate scan tool connected and ready

Step 2: Access the ECM Programming Menu

- Connect your scanner to the OBD-II port (usually under the dashboard)

- Turn the ignition to the “On” position, but don’t start the engine

- Navigate to the injector programming or calibration section in your scanner

- Select the appropriate engine and vehicle model when prompted

Step 3: Input the Trim Codes

The exact process varies by vehicle, but generally follows this pattern:

- Select “Injector Programming” or a similar option

- Choose the cylinder or injector position you’re programming

- Enter the trim code exactly as it appears on the injector

- Confirm entry and continue to the next injector

- Repeat for all injectors in sequence

Step 4: Verify and Save the Programming

- Review all entered codes for accuracy

- Save the programming to the ECM (follow scanner prompts)

- Cycle the ignition off and back on when instructed

- Allow the scanner to verify successful programming

Step 5: Test Your Work

- Start the engine and let it reach operating temperature

- Check for any warning lights or error codes

- Test drive the vehicle, paying attention to smoothness at idle and under acceleration

- Use the scanner to check live data, confirming balanced fuel trims across all cylinders

Remember that some vehicles require an additional “relearn” procedure after programming injector codes. Your scanner or service manual will indicate if this is necessary and provide the specific steps.

Common Problems and Troubleshooting

Even with the best preparation, you might encounter some roadblocks when working with injector trim codes. Here are solutions to the most common issues:

Unreadable or Missing Codes

If you can’t read the codes on your injectors, you have a few options:

- Clean the injector thoroughly with brake cleaner and try again with better lighting

- Contact your dealer with the injector part number to get the codes

- Send the injector to a specialty shop for testing and code retrieval

- For some engines, replacement with a new coded injector may be necessary

Programming Errors

If you get an error during programming:

- Double-check that you’re entering the correct format (some require dashes or spaces)

- Ensure your scanner is compatible with your vehicle’s ECM

- Verify that your battery voltage is sufficient (low voltage often causes programming failures)

- Try a factory reset of the injector programming and start over

Performance Issues After Programming

If your engine runs poorly after programming:

- Verify all codes were entered correctly for each cylinder position

- Check for air leaks in the intake system

- Perform a complete ECM reset and reprogram

- Consider having injectors flow-tested to verify their actual performance matches the trim codes

Scanner Limitations

Not all scanners can program injector codes. If yours can’t:

- Consider a scanner upgrade or rental for this specific task

- Visit a dealership or specialized diesel shop for programming

- Some independent shops have subscription-based dealer tools that can handle this job

Benefits of Properly Calibrated Injector Trim Codes

Taking the time to properly find and program your injector trim codes pays off in multiple ways:

Performance Improvements

Correctly programmed injectors mean each cylinder receives precisely the right amount of fuel. This translates to:

- Smoother idle quality

- Improved throttle response

- More consistent power delivery

- Elimination of hesitation or surge during acceleration

- Many customers tell us they’re amazed at how different their engine feels after proper injector calibration – like getting a tune-up and injector cleaning all at once.

Fuel Economy Gains

When each injector delivers exactly the right amount of fuel, nothing gets wasted. Our customers typically report:

- 2-5% improvement in fuel economy for gasoline engines

- Up to 8% improvement for diesel engines

- More consistent MPG readings in varying driving conditions

Over the life of your vehicle, these savings can add up to hundreds or even thousands of dollars.

Extended Engine Life

Balanced fuel delivery across all cylinders means:

- Reduced cylinder temperature variations

- More even piston and ring wear

- Less carbon buildup on valves

- Reduced oil contamination from unburned fuel

All these factors contribute to longer engine life and fewer repairs down the road.

Emissions Reduction

Properly calibrated injectors optimize the combustion process, resulting in:

- Lower NOx emissions

- Reduced hydrocarbon output

- Less particulate matter (especially important for diesels)

- Better chances of passing emissions testing

In today’s world of strict emissions standards, having your injectors properly coded can make the difference between passing and failing your next test.

When to Update or Re-enter Your Injector Trim Codes

Knowing when to update your injector trim codes is just as important as knowing how to do it. Here are the key times when you should check and possibly update your codes:

After Injector Replacement

This is the most obvious time – whenever you replace one or more injectors, you must program the new trim codes. Skipping this step is like putting the wrong prescription lenses in your glasses – things just won’t work right!

Following ECM Replacement or Updates

If your engine control module is replaced or undergoes a major software update, the injector trim codes may need to be re-entered. The new or updated ECM might revert to default values, causing performance issues.

When Experiencing Specific Performance Issues

Consider checking your injector programming if you notice:

- Rough idle that traditional tune-up doesn’t fix

- Cylinder misfires that persist after replacing spark plugs and coils

- Uneven power delivery or hesitation under load

- Failed emissions tests with no other obvious cause

During Major Service Intervals

For commercial vehicles or high-mileage engines, it’s good practice to verify injector trim codes during major service intervals (like 100,000 miles). Over time, vibration and heat can cause ECM memory issues that might affect injector calibration.

After Jump Starts or Electrical System Work

Major electrical system events – like jump starts, battery replacements, or electrical system repairs – can sometimes reset or corrupt ECM data. If you notice performance changes after such work, checking your injector programming is a smart troubleshooting step.

FAQs About Injector Trim Codes

What happens if I install injectors without programming the trim codes?

Skipping trim code programming can cause rough running, poor fuel economy, and potential damage over time. Your engine’s computer won’t be able to properly balance fuel delivery across cylinders, leading to performance issues and potentially failed emissions tests. Some newer vehicles may even enter a limited operation mode or set check engine lights when they detect non-programmed injectors.

Can I use generic or average trim codes instead of the specific ones?

While your engine will run with generic codes, you’ll miss out on the precision and performance benefits of proper coding. It’s like wearing shoes that are the right size but not designed for your specific feet – they’ll work, but not optimally. For best results, always use the exact codes specified for your injectors.

How much performance improvement can I expect after programming trim codes?

Most drivers notice immediate improvements in idle quality and throttle response. Fuel economy typically improves by 2-8% depending on engine type and previous condition. The difference is usually most noticeable in diesel engines and direct-injection gasoline engines, where precise fuel delivery is even more critical to performance.

Do aftermarket injectors come with trim codes?

Quality aftermarket injectors, like those we sell at FridayParts, come with proper trim codes. However, some budget brands may skip this crucial calibration step. Always verify that any aftermarket injector you purchase includes proper trim codes – it’s worth paying a bit more for correctly calibrated injectors.

Can I determine trim codes if they’re completely unreadable on my injectors?

If the codes are completely unreadable, you have three options: contact the dealer with your injector serial numbers, have the injectors flow-tested at a specialty shop to determine appropriate values, or replace them with new injectors that have proper coding. For critical applications, flow testing is the most accurate approach when original codes are lost.

At FridayParts, we understand how important properly functioning injectors are to your engine’s performance. That’s why we stock a comprehensive range of OEM-quality injectors with proper trim codes for virtually all engine types. Whether you’re replacing a single problematic injector or doing a complete set, our team is ready to help you find exactly what you need.

Remember Joseph from Cameroon, who needed that hard-to-find generator part? Just like we helped him, we’re here to help you find the perfect injectors for your application. With warehouses across North America, Germany, and China, we can get you the parts you need fast.

Have questions about injector trim codes or need help finding the right injectors for your engine? Contact our support team Monday to Friday, 9 am-6 pm EST at +1 833-308-1855 or email us at info@fridayparts.com.

Get your engine running at its best with properly coded injectors from FridayParts!