Aerial work platforms (AWPs) – like telescopic boom lifts, articulating boom lifts and rough-terrain scissor lifts – have a big job to do. On construction sites, these vital machines lift workers high up and keep them steady, and they’ve got to move across all kinds of ground too, from smooth concrete and asphalt to bumpy sand and mud. Tires are what connect these sky-high machines (they can reach over 100 feet up!) to the ground. How to choose the best tires? Fitting them with the right tires boosts performance, makes operations safer, and in the end, brings in more profit.

Why the Right Tire Choice Matters?

The tires on an aerial work platform (AWP), also called a mobile elevating work platform (MEWP), are the only part that touches the ground.

- Safety first: Tires are directly tied to stability. When the machine’s raised high up, the tires bear the weight of the whole unit, the operator and all the tools. Ill-fitting or badly worn tires can easily throw off balance, and in the worst cases, even lead to a rollover risk.

- Smooth operations: The right tires deliver enough traction to let the machine move around the job site with ease. No slipping, no getting stuck, less fuss—you position the machine faster, and the work gets done quicker naturally.

- Protecting the ground: Lots of indoor job sites, warehouses and finished flooring have strict tire requirements. Using the wrong tires can leave black marks, scuffs or even ruts. You’ll have to clean it up, and might even face fines—hitting your costs directly.

- Equipment Longevity: And last, tires are your lift’s main shock absorbers. The right tire cushions the axles, chassis and drivetrain from hard jolts and vibrations. That eases mechanical stress and wear on pricey parts, and makes the whole machine last longer.

Types of Aerial Work Platform Tires

Pneumatic Tires

These are just like car tires—you have to inflate them with air.

Pros

- Best shock absorption

- Smoother ride on bumpy ground, more comfortable for the operator

- Less impact on the machine

Cons

- Super vulnerable to nails, screws and other sharp debris common on job sites

- They’ll go flat once punctured, and the machine stops working right away

- Tire replacement is a hassle and comes with safety risks

That’s why pneumatic tires are rarely used on today’s scissor lifts and boom lifts. They’re only a good fit for areas with almost no risk of punctures.

Foam-Filled Tires

This is the most common choice for outdoor and rough terrain work. It has a standard pneumatic tire casing, but the inside is filled with special foam that hardens into a flexible, solid core.

Pros

- 100% puncture-proof—no worries about flat tires

- No unplanned downtime from air leaks

- Better cushioning than solid tires for a steadier ride

- Wide ground contact area, so better flotation on soft ground

Things to note

- Heavier than pneumatic tires

- A bit more expensive upfront

But all in all, they’re extremely reliable—so they’ve basically become the industry standard for outdoor AWPs.

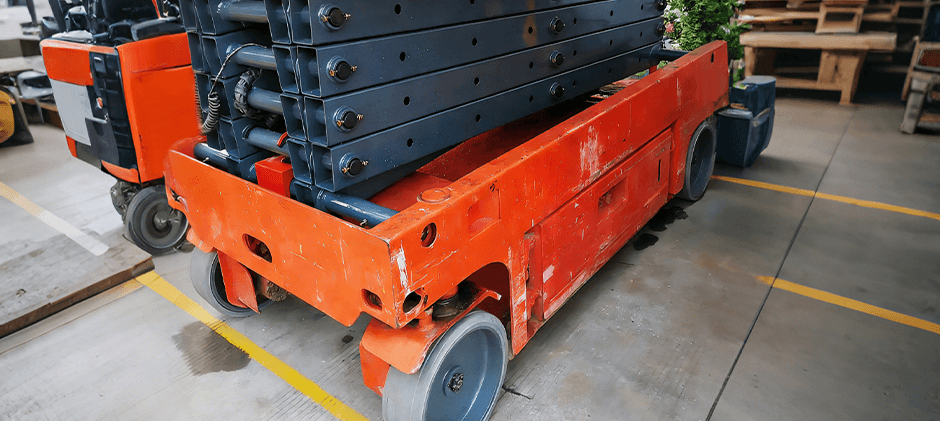

Solid Rubber / Press-On Tires

These are a single block of rubber, pressed directly onto the wheel rim.

Pros

- No air, no foam inside

- Almost zero maintenance needed

- Super wear-resistant, unaffected by gravel and debris

Cons

- Worst shock absorption out of the three

- Really bumpy to drive on

- All ground impacts transfer straight to the machine and operator

They’re a better fit for smooth, hard surfaces—like warehouse, factory and concrete floors, and not ideal for complex job sites.

How to Choose the Best Tires for Scissor & Boom Lifts?

The single most important factor in choosing the best scissor & boom lift tires is the job site itself. Let’s look at scenarios you’ll encounter.

Indoor Work on Smooth, Finished Surfaces

If you’re working indoors on smooth, finished floors—like in warehouses, data centers, malls or hospitals—your main thing is protecting the floor. For these spots, choose solid non-marking tires. They’re made with a special gray or white rubber that won’t leave black scuffs or marks when you’re turning tight. Their smooth tread hits more of the floor, so you get way better stability on flat ground. Foam-filled non-marking tires work too, but solid ones are way more durable and totally low-maintenance—they’re the better pick for regular indoor work.

“Using the wrong tires for just one indoor job can cost more to fix the floor damage than a whole set of non-marking tires. It’s a smart investment for looking professional and saving money.”

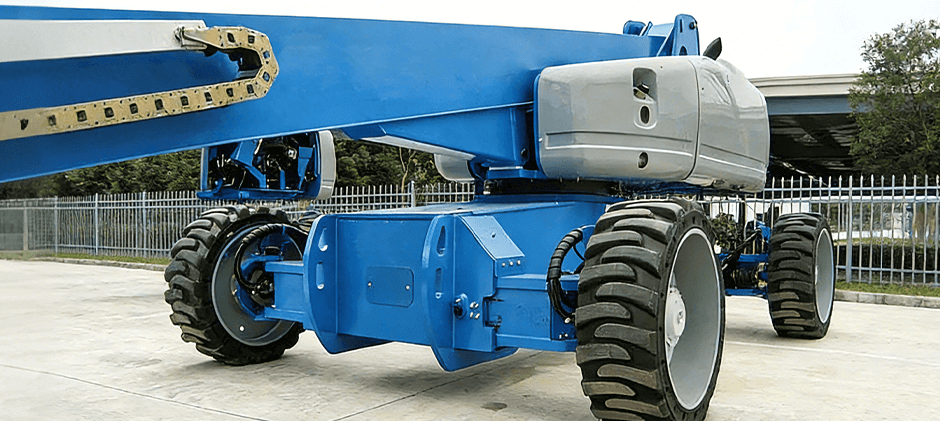

Outdoor Work on Rough, Unimproved Terrain

If you’re working on new construction sites, farmland, or any muddy, gravelly, debris-strewn areas, your main priorities change completely. Here, what matters most is maximum traction and total puncture resistance. And for this kind of terrain, foam-filled tires with lug tread are the obvious choice.

Foam-filled design means your machine keeps running. Puncture protection is a must. The tread pattern is just as key: you need deep, tough lug tread (the tractor kind). Those deep grooves dig into soft ground like dirt and mud, giving you the forward grip you need to stop your lift from getting stuck and wasting valuable time.

Mixed-Use (Indoor and Outdoor on Paved/Hard Surfaces)

A lot of jobs mean moving between different areas, like a contractor working inside a building, then heading out to the paved parking lot right next to it. For this kind of mixed use, you choose a jack-of-all-trades tire that protects floors inside and holds up outside, too.

The perfect choose here is a non-marking foam-filled tire. It’s puncture-proof for all the hazards you run into outdoors, and the non-marking rubber keeps indoor floors safe. As for the tread, an all-terrain or turf-friendly design is usually the best middle ground. It gives you better grip outside than a smooth tire, but it’s not as tough as deep lug tread—those get loud and make the machine vibrate on hard surfaces.

Conclusion

Choose the best tires for your scissor lift or boom lift all comes down to sizing up your work site clearly. Just match the tire’s build (air-filled or solid), material (non-marking or black) and tread pattern to where you work. With FridayParts, it’s easy to find top-quality, fairly priced tires for your lift. Browse our lift tires right now!

Frequently Asked Questions

What’s the main difference between solid and foam-filled scissor & boom lift tires?

The key difference lies in their construction and real-world performance. A solid tire is a single block of rubber – ultra-durable but very stiff, with practically no cushioning at all. A foam-filled tire is a standard tire casing filled with a soft, puncture-proof polymer. This gives it a degree of flexibility and shock absorption, delivering a much smoother ride than a solid tire, and it’s far better suited for uneven ground.

Do I need a different type of tire for indoor vs. outdoor use?

Yeah. Indoors, it’s mostly smooth floors, so use non-marking tires to keep from scuffing the ground. Outdoors on rough terrain, puncture resistance and grip are the top things to care about—solid tires are the standard pick for this. If you work both inside and out, choose a non-marking solid tires that are perfect for the job.

How do I know when it’s time to replace my lift tires?

Replace your tires when they’re worn or damaged. Most solid and foam-filled tires have a wear line or a “60J” mark on the sidewall. When the tire wears down to that line, it’s worn out and needs replacing. Also check your tires regularly for obvious damage—like deep cuts, chunks of rubber missing, or the tire separating from the rim. Using damaged tires is really dangerous, so never ignore this.