Change your fuel filter regularly is basic maintenance. The filter catches dirt and impurities in the fuel, keeping the fuel system running smoothly. This eases the load on your fuel pump and helps it last longer. Over time, the filter gets clogged. This drops fuel flow and pressure. If your machine loses power, it’s a sure sign the filter is dirty. Always replace it according to the manufacturer’s recommended schedule.

Where Is My Fuel Filter Located?

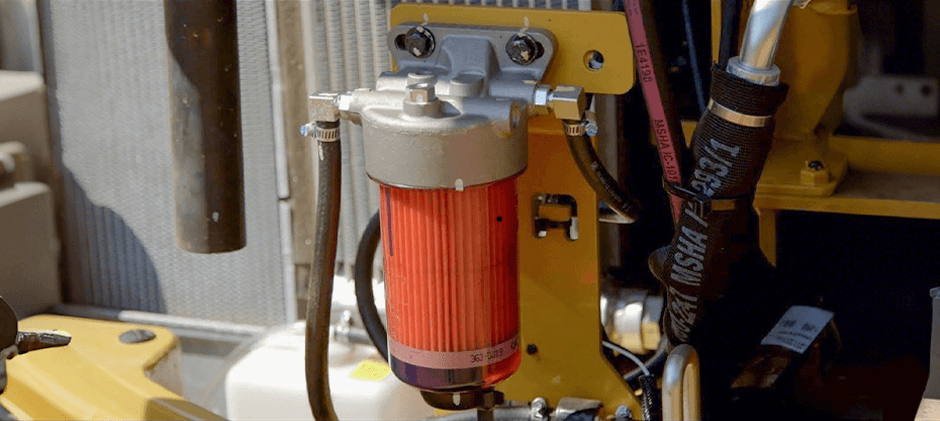

Heavy-duty off-road equipment uses a more durable multi-stage fuel filter system, because diesel fuel is more likely to get contaminated and mixed with water. There are usually two main fuel filters on the machine.

The primary fuel filter is also called a water separator. It mainly filters out larger impurities in diesel, and most importantly, separates water from the fuel. This filter assembly usually has a clear plastic or glass bowl at the bottom, letting you see directly if there’s water or sediment inside. There’s also a small drain valve or petcock at the bottom of the bowl. It’s usually installed in an easy-to-reach place—either on the machine’s chassis frame, inside a side access panel, right on the fuel line between the fuel tank and the engine.

The secondary fuel filter is also known as the fine fuel filter. After diesel passes through the primary filter, it flows to this one for a final fine filtration before entering the precision parts inside the engine. This filter looks just like a regular spin-on oil filter, a painted metal canister, with no clear bowl at the bottom. It’s almost always mounted directly on the engine block, usually near the high-pressure fuel pump or right next to the fuel injection system it’s meant to protect.

If you’re not sure where the filters are exactly, check the machine’s operator’s manual or service manual. It’s the most authoritative reference, with diagrams that clearly mark the exact positions of the fuel filters for your specific model.

How To Replace a Fuel Filter?

You can change the fuel filters on your own. Follow these steps to avoid fuel contamination.

Prep Work

Park the machine on flat ground, turn off the engine and let it cool down. Wear safety goggles and nitrile gloves to keep diesel off your skin. A new set of quality fuel filters (primary and secondary), a filter wrench, a drain pan for spilled fuel, and clean, lint-free rags.

Clean the Area

Wipe or blow off the area around both filter housings with a rag or compressed air. This stops dirt and debris from getting into the clean part of the fuel system while you work.

Replace the Primary Filter / Water Separator

- If your machine has a fuel shut-off valve (near the fuel tank or primary filter), close it first.

- Put the drain pan under the primary filter assembly.

- Unscrew the clear bowl at the bottom of the filter carefully – some fuel will leak out.

- Use a filter wrench to loosen the main filter element, then unscrew it by hand and take it off.

- Clean the inside of the clear bowl. Check the bowl’s O-ring, and replace it if there’s a new one in the filter kit.

- Take the new primary filter, and lightly coat its gasket with a little clean diesel.

- Screw the new filter onto the housing until the gasket touches it, then hand-tighten it another 1/2 to 3/4 turn. Don’t over-tighten.

- Put the clean bowl back on the bottom of the new filter.

Replace the Secondary (Fine) Filter

- Move the drain pan under the secondary filter on the engine.

- Use the filter wrench to loosen the old filter, then finish unscrewing it by hand and lower it carefully – it’ll be full of fuel.

- CRITICAL STEP: Pre-fill the new secondary filter with fresh, clean diesel. This is essential for modern high-pressure common rail (HPCR) systems. It keeps as much air out of the system as possible – air is hard to get rid of and can stop the engine from starting.

- Lightly coat the gasket of the pre-filled new filter with clean diesel.

- Screw the new filter onto its housing carefully until the gasket touches it, then hand-tighten another 1/2 to 3/4 turn (same as the primary filter).

Even a tiny grain of sand can damage a high-pressure fuel system. Keeping everything clean while changing filters isn’t just a good habit – it protects your equipment.

Prime the Fuel System

This is the most important final step. You need to get all the air out of the system that got in during the change.

- Open the fuel shut-off valve you closed earlier.

- Find the manual priming pump – it’s usually a small plastic plunger or button on top of the primary or secondary filter housing.

- Start pumping the primer. At first, it’ll feel loose with little resistance. Keep pumping until the plunger gets very firm and hard to push. This means the filter housings are full of fuel and pressure has built up – it may take 50 to 100 pumps.

- After priming, check all connections for fuel leaks.

Start the Engine

Turn the key to start the engine. There’s still some air left in the injectors that needs to work its way out, so it might crank a few extra seconds to fire up, or run a little rough at first—it’ll smooth out quickly. Let the engine idle for a few minutes, then do a final check around the filter gaskets and all fittings to make sure there’s no fuel leaking.

How Often to Change the Fuel Filter?

Knowing how to maintain your heavy equipment is key, and knowing when to do it matters just as much. All maintenance timelines for heavy gear go by operating hours.

For most excavators, loaders and other off-road machines, the basic rule is: change both the main and secondary fuel filters every 500 operating hours. That timeline might need to be shorter, though. Replace the filters more often if you:

- Run your machine in super dusty, dirty conditions

- Think you’ve got a batch of bad or contaminated fuel

- Keep finding a lot of water or gunk in the water separator bowl of your main fuel filter

Always check your operator’s manual for the maker’s exact guidelines, but sticking to the 500-hour mark as a standard is a safe, dependable way to protect your engine.

How Do I Know If My Fuel Filter Needs Changing?

A clogged fuel filter cuts down fuel flow. By the time these clear signs pop up, your engine’s already short on fuel—so swap out the filter proactively, don’t wait.

- Sluggish power: Feels weak, especially when doing heavy work like digging, lifting a full bucket or climbing hills.

- Rough engine or misfires: Uneven fuel supply makes the engine run unsteady.

- Hard to start: Takes longer to fire up, thanks to restricted fuel flow for startup.

- Engine stalls: Cuts out the second you rev it up or put it to work.

- Higher fuel use: The engine’s less efficient, burning more diesel to get the same job done.

- Dashboard warnings: Most modern machines have sensors that light up a “low fuel pressure” light or throw a fault code if the pressure’s too low.

If you notice any such problems, replacing the fuel filter is the easiest and most cost-effective way to do it.

How Much Does a Diesel Fuel Filter Replacement Cost?

When you’re thinking about cost, it’s key to compare the low price of filter parts against the huge cost of fixing your machine if something breaks.

Part costs: Fuel filters are way more affordable than you’d think. For most common excavator and loader models in the North American market, a set of high-quality aftermarket primary and secondary fuel filters only costs $50 to $150. They give you the same (or even better) protection as OEM parts, but for a tiny fraction of the price.

Labor costs: If you have a mechanic change them for you, it’ll take about 1 to 1.5 hours of their time—and you’ll pay for that. Do it yourself, and you save all that labor money.

Now think about what happens if you don’t change the filters. Dirt and water can get past a clogged filter and ruin your high-pressure fuel pump and injectors. Just one new fuel injector can cost over $1,000, and a high-pressure pump can set you back thousands more. Suddenly, spending a little on regular filter changes feels like nothing. It’s the cheapest insurance you can buy to protect your engine’s fuel system.

Protect Your Engine

Regularly changing your fuel filters is not just routine maintenance; it’s a fundamental practice for preserving the health and power of your heavy equipment. By following a 500-hour interval and using the correct replacement procedure, especially pre-filling and priming, you prevent costly downtime and catastrophic engine damage. As a supplier of high-quality aftermarket parts, FridayParts is committed to providing a vast inventory of filters compatible with many heavy equipment brands. Our goal is to give you access to reliable, affordable products so you can perform this critical maintenance with confidence and keep your machinery earning for you.