When your tractor or excavator must persist in operation from the first light of dawn until the fading of dusk, or traverse rugged terrains under conditions of insufficient illumination, the reliability of headlight bulbs constitutes an indispensable element both for productivity and for the assurance of safety. To comprehend the anticipated longevity inherent in diverse bulb technologies assists you in the arrangement of maintenance schedules, the compilation of replacement budgets, and the discerning selection of lighting solutions in accordance with the severe operational requisites imposed upon the equipment.

How Long Do Headlight Bulbs Last?

The service longevity of headlight lights in off-road machinery varies depending on the adopted technology and operational circumstances. Since most off-road equipment labors under extremely harsh surroundings, the incessant vibration, ceaseless dust intrusion, and drastic temperature fluctuation accelerate the attrition of components. Excavators, bulldozers, mining trucks, and agricultural machinery lights endure stresses substantially greater than those imposed upon automotive bulbs. The prolonged operation, the rugged terrain vibration, and the erosive assault of dust and debris together constitute a severe environment that perpetually tests the durability of the bulb.

The essential distinction resides in the necessity that off-road light systems withstand conditions far exceeding the realm of ordinary roadway utilization. When compared with standard automotive applications, such factors as hydraulic system oscillation, engine-generated heat, dust permeation, and uninterrupted operational cycles inevitably shorten the bulb’s duration. Conventional halogen bulbs, which might persist for 500–1000 hours in ordinary vehicular usage, may discover their existence diminished to 500–600 hours when installed in construction or agricultural heavy-duty machines. In contrast, the advanced LED systems, though demanding higher initial pecuniary outlay, may bestow 30,000–50,000 hours of service in off-road light systems, and therefore increasingly attract the attention of fleet managers intent upon the reduction of maintenance frequency and operational expenditure.

Average Lifespan of Different Types of Headlight Bulbs

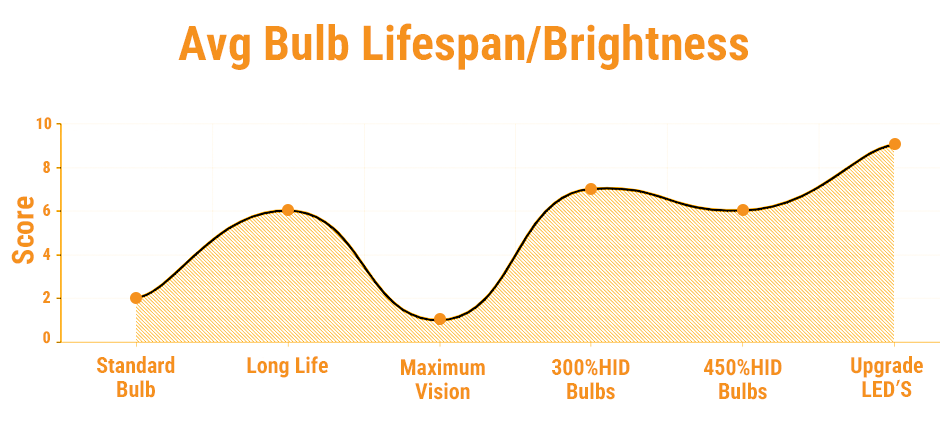

The type of bulb in your machine is the single biggest factor determining its life expectancy. To visualize the trade-offs between different types of bulbs in terms of performance and longevity, we can look at their overall value score. This score considers brightness, lifespan, and durability together.

As the chart shows, not all bulbs are equal. Upgrade LEDs come out on top with the highest score, representing the best balance of brightness, extreme longevity, and durability. High-performance 300% HID Bulbs also score very well, offering immense brightness. Interestingly, Long Life bulbs and very bright 450% HID Bulbs end up with a similar score, showing the trade-off between lifespan and pure power. At the bottom, Maximum Vision bulbs score the lowest, highlighting a critical point: the brightest bulbs are often the ones that burn out the fastest, making them a poor choice for equipment that runs for long hours.

Halogen Headlights

For decades, halogen bulbs have maintained the position of conventional configuration. Their operational mechanism consists of heating a tungsten filament enclosed inside a capsule of halogen gas, thereby producing a yellowish-white radiance.

- Life Expectancy: generally 500 to 1,000 hours.

- Merits: inexpensive in nature, easily procurable.

- Cons for Heavy Equipment: the utmost frailty lies within the filament itself. Continuous violent oscillations of bulldozers, excavators, or tractors may induce premature rupture, obliging recurrent replacement. Moreover, their elevated thermal emission and inferior efficiency impose an additional burden upon the electrical system.

HID (Xenon) Headlights

High-Intensity Discharge (HID) bulbs, frequently denominated xenon lamps, emit luminous energy by generating an electrical arc between dual electrodes inside a vessel suffused with xenon gas.

- Life Expectancy: commonly 2,000 to 5,000 hours.

- Merits: In comparison to halogen, they exhibit augmented brightness, producing intense white illumination and covering broader spatial dimensions. Such attributes render them apt for high-speed or wide-area operations.

- Cons for Heavy Equipment: their constitution is more intricate, requiring a ballast to initiate and modulate power. They demand a temporal duration to attain maximal luminosity. Over-extended usage, diminution of brightness, or chromatic alteration may manifest. While more enduring than halogen, they remain less resilient than LED.

LED Headlights

Light Emitting Diodes (LED) represent the contemporary standard for applications of a heavy-duty nature. They generate radiance through semiconductor action, with exceedingly low energy consumption and negligible thermal output.

- Life Expectancy: up to 30,000 to 50,000 hours.

- Pros:

1. Extreme durability: absence of filament grants resistance to vibration and impact, thus excellently suitable for off-road machinery.

2. Energy efficiency: they consume markedly reduced electrical power, thereby alleviating alternator and battery stress.

3. Instant brightness: full illumination is achieved upon mere activation of the switch. - Cons for Heavy Equipment: the principal consideration resides in thermal governance. LEDs remain sensitive to elevated temperatures; therefore, installation must be within meticulously engineered housings that possess heat sinks to ensure longevity.

5 Factors Affecting Headlight Bulbs’ Lifespan

Even if one procures the most excellent bulb, under excessively harsh operational circumstances, premature failure may yet occur. The following constitute five determinants that accelerate the diminishment of lifespan for equipment headlights.

1. Severe Vibration and Impact

This represents the foremost adversary for traditional headlight bulbs, particularly halogen ones. During traversal upon uneven terrain, each bump, oscillation, and tremor transmits shockwaves into the machine. For halogen bulbs, such stress may result in the fragile tungsten filament fracturing, thereby inducing immediate failure.

2. Prolonged Usage Duration

Unlike private automobiles, which might operate merely one or two hours daily, agricultural and construction machinery frequently sustain continuous operation for eight, twelve, or even more hours, day after day. Such unremitting punctual functioning naturally accelerates the wearing of components. If your operation depends upon nocturnal or dim-light conditions, the attrition of bulbs proceeds with even greater rapidity.

3. Moisture and Contaminants

Heavy-duty equipment is unavoidably exposed to diverse environments. Rain, ambient humidity, or moisture generated by high-pressure washing may infiltrate headlight housings with inadequate sealing. Condensation will corrode electrical contacts and bulb bases, culminating in malfunction. Meanwhile, dust and filth may enshroud the lens, accumulating heat and inducing excessive temperature, which curtails bulb longevity.

4. Electrical System Voltage

The electrical system of the machine is designed to function within a prescribed voltage domain (e.g., 12V or 24V). Should the alternator fail or should the voltage regulator exhibit dysfunction, voltage spikes may be transmitted toward the headlights. Such overvoltage renders bulbs brighter, yet simultaneously produces overheating of components, thereby drastically abbreviating service life.

5. Improper Handling During Installation

This factor, albeit simple, remains of utmost importance. One must never grasp halogen or HID bulbs’ glass directly with bare hands. Upon heating, natural oils from the skin create “hotspots” on the glass surface. Such uneven heating diminishes the strength of the glass, precipitating cracking or, in extreme cases, shattering.

How to Extend the Life of Your Equipment Headlights?

Although one is incapable of altering the severe laboring environment of the machine, yet measures can be undertaken in order to maximize the prolongation of the lamp’s service longevity.

- Choose High-Quality Bulbs: This constitutes the foremost and most essential step. To allocate investment into durable, superior-grade, and aftermarket lights elaborately designed for heavy-duty utilization is always worthwhile. They frequently demonstrate high cost performance and are suitable to become the first selection as consumable parts. FridayParts, being an excellent aftermarket supplier, can fulfill both the requirement of quality and the expectation of price when you select illumination bulbs.

- Regularly Clean Headlight Lenses: A thick accumulation of dust or mud upon the lens may behave in the manner of an insulator, absorbing heat and damaging the bulb. Kindly employ a soft cloth and proper detergent to maintain the lens in a state of cleanliness.

- Ensure the Housing is Properly Sealed: Frequently inspect the rubber gaskets and sealing components surrounding the headlamp enclosure. Should they appear cracked or worn, substitute them immediately in order to prevent moisture from intruding inside.

- Handle New Bulbs with Care: While installing fresh bulbs, it is necessary to wear clean gloves or apply a cloth. Grasp the metallic or plastic base, rather than the glass portion.

- Check Your Electrical System: If you perceive the necessity of replacing bulbs with abnormal frequency, allow a technician to examine the charging system of your machine to ascertain that it delivers a stable and correct voltage.

Are Faulty Headlights A Bigger Issue?

On a worksite, a faulty light is a much bigger issue than just a potential ticket. It’s a major safety hazard. A single burnt-out headlight dramatically reduces your ability to see obstacles, ditches, or personnel on the ground. It also makes your multi-ton machine less visible to others. This can be a direct violation of worksite safety protocols (like OSHA standards) and puts everyone at risk. Addressing a failing headlight isn’t just about replacing a bulb; it’s about maintaining a safe working environment.

Ready to Upgrade Your Visibility?

The endless replacing of dim or malfunctioning halogen bulbs not only produces vexation but also consumes time and money in futility. Data has manifested that the adoption of modern LED technology becomes the most efficacious pathway to break the ceaseless cycle of frequent replacement. Nevertheless, not every upgrade manifests in an identical manner. When you devote your investment into high-quality, high-power aftermarket headlight bulbs, you may then obtain the supreme durability and longevity of top-class LED, without bearing the excessive price of original factory parts. Therefore, if you are already prepared to raise the visibility of your equipment and at the same moment greatly diminish the burden of maintenance, the exploration of proper lighting options within FridayParts shall constitute your subsequent step.