Whether you’re running a skid steer on a remote job site or a compact excavator in harsh terrain, the starter motor is the unsung hero that brings your equipment to life. But how long should you expect it to last, and what really determines its lifespan? In this guide, we’ll uncover everything you need to know about starter durability, warning signs, and smart preventive steps.

How Does the Starter Motor Work?

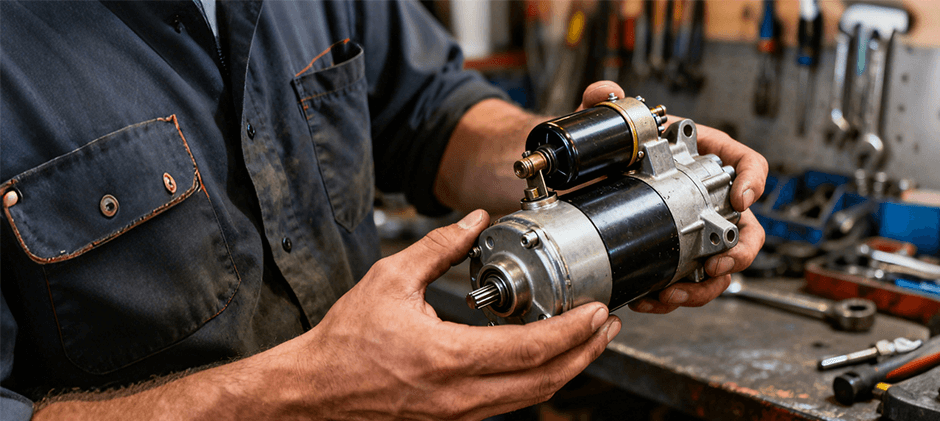

In every piece of off‑road machinery — backhoes, loaders, graders, and tractors — the starter motor transforms stored electrical energy from the battery into mechanical rotation to crank the engine. That rotation allows fuel combustion to begin, starting the engine.

Although simple in concept, the starter operates under demanding conditions. Dust, vibration, high current flow, and temperature swings make the part work harder than starters in passenger vehicles, which means paying attention to maintenance and service life is more important than ever.

Average Lifespan of Motor Starter

A well‑built heavy equipment starter can typically last between 4,000 to 6,000 start cycles — roughly 5 to 8 years under moderate conditions. Machines exposed to heavy daily duty or operated in muddy, salty, or dusty environments might see a shorter lifespan of 3 to 5 years.

Here’s a quick comparison:

| Operating Conditions | Expected Lifespan | Wear Characteristics |

|---|---|---|

| Light workload, clean environment | 7–8 years | Minimal brush wear |

| Heavy-duty excavation or quarry use | 3–5 years | High heat and contamination |

| Cold climate, frequent starts | 4–6 years | Increased stress on relays |

| Aging electrical system (weak battery) | 2–4 years | Overloaded draw and solenoid wear |

Mileage or operating hours don’t tell the full story — the number of starts matters more. A compact loader working in short stop‑and‑go cycles wears a starter faster than a generator that runs for long intervals between starts.

Key Factors Affecting Starter Lifespan

Several interrelated elements influence how long your starter will perform reliably:

1. Electrical System Health

A weak battery or corroded terminals make the starter draw excessive current. This causes overheating of the solenoid coil and contacts, leading to permanent damage.

2. Environment and Working Conditions

Dust, mud, oil mist, or excessive vibration degrade the internal brushes and bearings. Off‑road machinery often faces heavy vibration from uneven ground — a prime stressor for electrical components.

3. Installation and Alignment

An improperly aligned installation can cause the pinion gear to grind against the flywheel, producing metal shavings and heat that quickly wear the motor.

4. Component Quality

High-quality aftermarket starters use durable brushes, sealed housings, and precision-machined gears. Cheap replacements often fail early due to poor electrical contact or substandard insulation.

5. Maintenance Discipline

Regularly inspecting wiring, cleaning terminals, and checking torque on mounting bolts prevents small issues from escalating into a costly breakdown.

Signs Your Starter Is Bad

Recognizing early warning signs keeps you from getting stranded in the field. Common symptoms of a deteriorating starter motor include:

- Slow or hesitant crank, even with a charged battery

- Clicking noise when turning the ignition key

- Grinding sound from the bell housing

- Intermittent start success — sometimes it works, sometimes not

- Burning odor or heat near the starter casing

If you notice any of these, avoid forcing repeated starts. Each attempt creates more heat and current draw that could destroy the remaining coil insulation.

Causes of Premature Starter Failure

Sometimes failure happens earlier than expected. Understanding why helps prevent it in future machines:

| Cause | Description | Result |

|---|---|---|

| Over‑cranking | Holding the key or start switch too long | Burned solenoid contacts |

| Weak battery | Forcing the starter to draw higher amperage | Overheated armature |

| Vibration fatigue | Repeated vibration loosens internal bolts | Intermittent contact |

| Oil contamination | Seepage through seals or lines | Short circuits/arc damage |

| Poor grounding | Interrupted electrical flow | Sporadic starts |

| Low-quality replacement parts | Inconsistent current delivery | Short lifespan |

Diagnostic Checklist Before Replacement

Before concluding the starter is bad, confirm all related components are in good working order:

- Test Battery Voltage — Should read 12.6V or higher (for 12V systems).

- Inspect Power Cables & Connectors — Tight, corrosion-free, and intact insulation.

- Check Starter Relay — Listen for a click; replace faulty relays immediately.

- Measure Current Draw — Compare against manufacturer specs to detect motor drag.

- Verify Mounting Alignment — Misalignment causes grinding or uneven gear wear.

A little diagnostic effort can save unnecessary repairs — sometimes, what appears to be a dead starter may just be a loose wire or weak relay.

Maintenance Schedule for Longer Service Life

Building preventive care into your equipment routine can add years to your starter’s working lifespan. Here’s a simple inspection schedule:

| Interval | Check / Action | Purpose |

|---|---|---|

| Every 250 hours | Clean terminals and battery posts | Maintain efficient current flow |

| Every 500 hours | Inspect starter alignment and bolts | Prevent vibration damage |

| Every 1,000 hours | Test voltage drop and current draw | Detect hidden internal resistance |

| Every 2,000 hours | Full starter performance check | Replace if nearing wear limit |

Keep a log of start cycles or operating hours — this helps predict when preventive replacement might be needed before total failure.

Final Thoughts

A reliable starter doesn’t just save time; it keeps your entire operation productive. Regular checks, clean connections, and smart part selection can easily double its lifespan. When signs of wear appear, replacing it early with a proven unit from a starter motor ensures your equipment stays ready for tough conditions — from dusty loader yards to remote construction sites.FridayParts stands out as your dependable aftermarket supplier, offering high‑quality products, wide compatibility, and affordable prices — helping off‑road operators reduce downtime and keep performance at its best.