Within the realm of heavy machinery, the mighty force generated by the hydraulic system grants excavators the capacity to lift tons of earth and empowers bulldozers to move tremendous burdens. The hydraulic pump converts the engine’s mechanical energy into hydraulic pressure that operates the boom, bucket, and blade. If your curiosity is stirred toward the inner workings of the hydraulic pump working principle, read on. The present guide shall unfold in detail the operational principles of hydraulic pumps, survey the varieties most commonly encountered in heavy equipment, and elucidate why the proper maintenance of this vital system stands as the cornerstone of enhanced productivity.

What is a Hydraulic Pump?

The core of a hydraulic pump is a kind of mechanical contrivance that obtains rotational energy from the engine or the electric motor, and thereafter converts it into hydraulic energy in the form of fluid flow. It is a widespread misconception among people that the pump itself is capable of generating pressure. In truth, the sole function of the pump is to bring forth a continuous movement of fluid. Only when the fluid encounters resistance—such as the weight of the load lifted by a hydraulic cylinder—does pressure come into being. Without the pump, the entire hydraulic system would merely be a congregation of pipes and oil.

How Does a Hydraulic Pump Work?

To understand the hydraulic pump working principle in the context of heavy equipment, let’s trace the power from the engine to the attachment. The process is a masterpiece of engineering that performs two primary functions.

- Firstly, the mechanical operation of the pump shall generate a vacuum at the inlet. As the internal components of the pump commence rotation, expanding chambers are thus formed, through which the hydraulic oil is drawn from the reservoir (oil tank) into the suction pipe. It resembles the manner in which one employs a straw to draw liquid — it is precisely the suction created by the pump that impels the fluid to move.

- Secondly, the mechanical motion of the pump conveys the liquid toward the outlet and compels it into the hydraulic pump system. Thereafter, the rotating elements establish contracting chambers, by whose force the entrapped fluid is expelled from the pump’s discharge port.

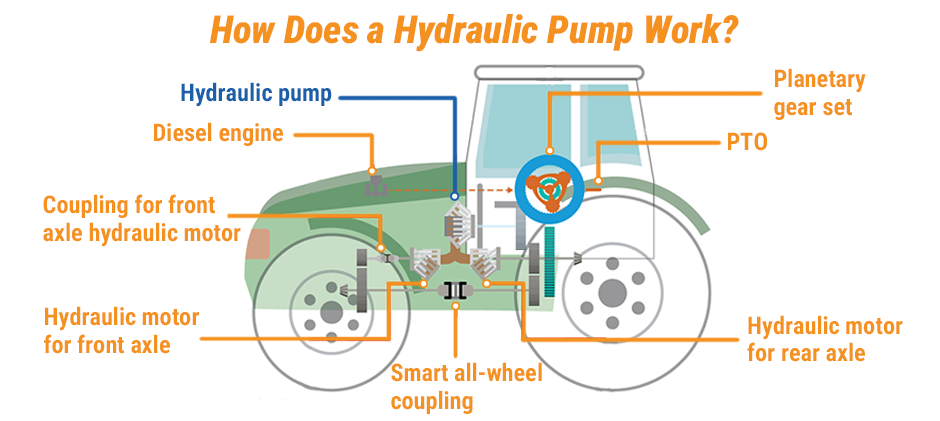

Let’s apply this to a farm tractor with a front-end loader.

- The diesel engine of the machine drives the shaft that connects to the hydraulic pump.

- When the pump begins to spin, it draws hydraulic oil out from the reservoir.

- Then, at a certain flow rate — say, in gallons per minute — the pump sends the oil toward the main control valve block.

- Once the operator moves the control lever, a specific valve opens, guiding the oil to a hydraulic cylinder — for instance, the lift cylinder of the front loader arm.

- The hydraulic oil pushes the piston inside the cylinder, but since the piston must raise the heavy loader arm and a bucket full of gravel, it doesn’t move so easily. This resistance against the oil flow builds up tremendous pressure in the system, measured in PSI or bar.

So, the hydraulic pump creates flow, while the load creates pressure. The greater the resistance, the higher the pressure the pump has to overcome in order to keep the hydraulic oil moving.

Types of Hydraulic Systems in Heavy Equipment

Hydraulic pumps belong to the family of positive displacement pumps, which means that with every single turn, they push out a definite amount of fluid. Yet, there exist many designs of such pumps, each carrying its own peculiar traits, suiting them to various kinds of work. Among these, the gear pump, vane pump, and piston pump are the three most often seen in heavy-duty machinery.

Gear Pumps

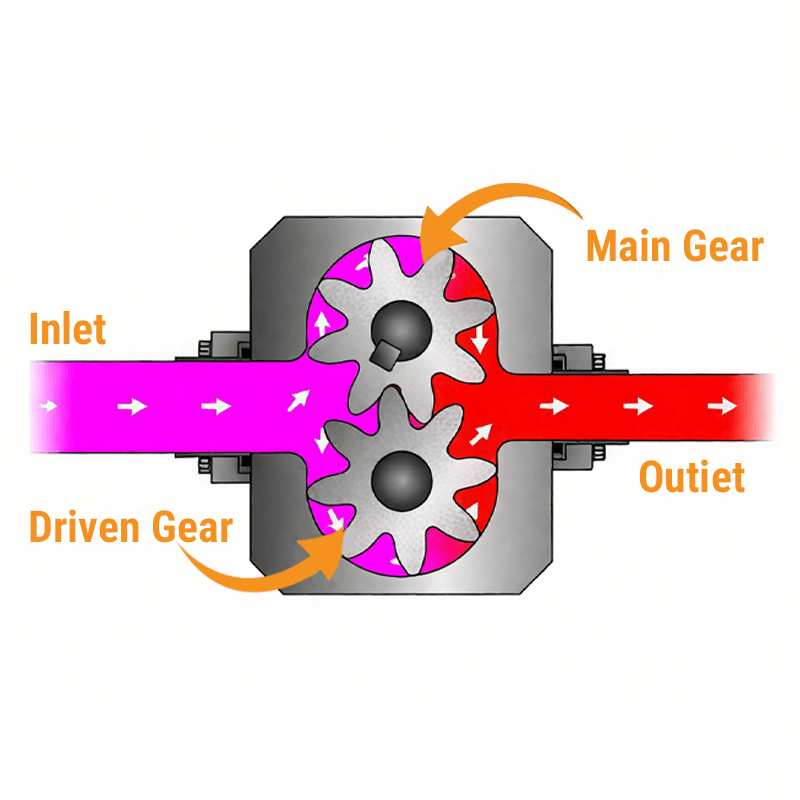

Gear pumps are one of the simplest and most robust pump designs. They work by trapping fluid between the teeth of two meshing gears and the pump’s housing. As the gears rotate, fluid is drawn from the inlet, carried around the outside of the gears, and then forced out of the outlet as the gear teeth mesh back together.

- External Gear Pumps: employ two identical interlocking spur gears.

- Internal Gear Pumps (Gerotors): employ one internal rotor and one external rotor. The internal rotor possesses one tooth fewer than the external rotor, thereby generating cavities that expand and contract concomitant with rotation.

- Best Suited For: Gear pumps are renowned for their reliability and cost-effectiveness. Within heavy-duty machinery, they are frequently utilized for auxiliary functions, power steering, or as pilot pumps, providing low-pressure oil to manipulate main hydraulic valves.

Vane Pumps

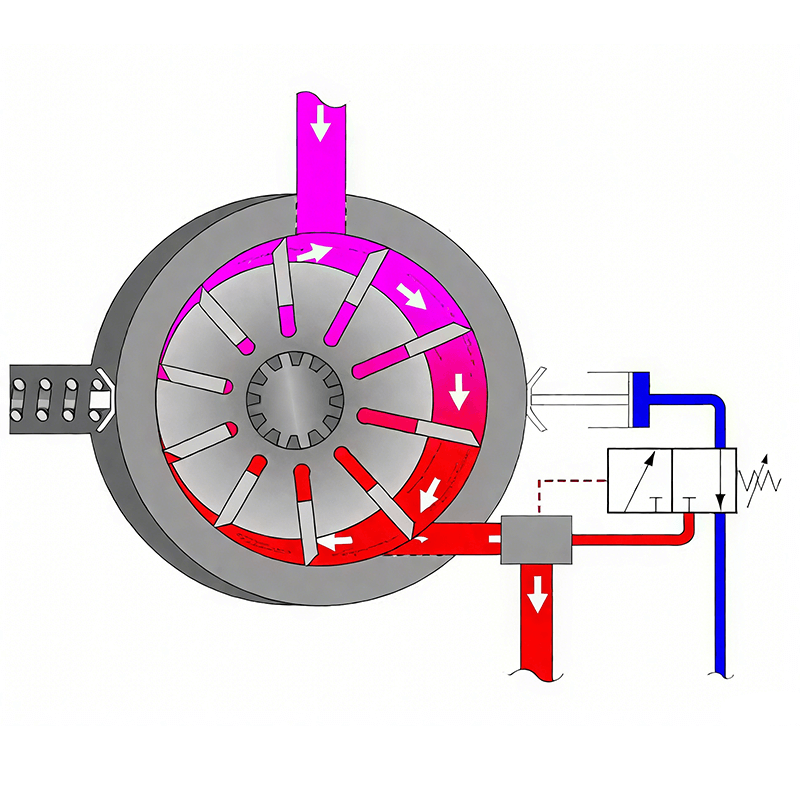

Vane pumps operate with a rotor that spins inside an elliptical or eccentric (off-center) chamber. The rotor has slots fitted with rectangular vanes that can slide in and out. As the rotor turns, centrifugal force and/or hydraulic pressure push the vanes outward, so they maintain contact with the chamber wall.

- How it Works: At the inlet side, concomitant with the outward movement of the blades, the chamber volume enlarges, thereby engendering a vacuum and drawing in the fluid. As the rotor persistently rotates toward the outlet side, the chamber volume contracts, compelling the fluid to discharge.

- Best Suited For: Vane pumps possess high efficiency and low noise, rendering them exceedingly appropriate for medium-pressure applications. Vane pumps may assume either a fixed-displacement or variable-displacement configuration, thus making them applicable to a diverse array of machine functions.

Piston Pumps

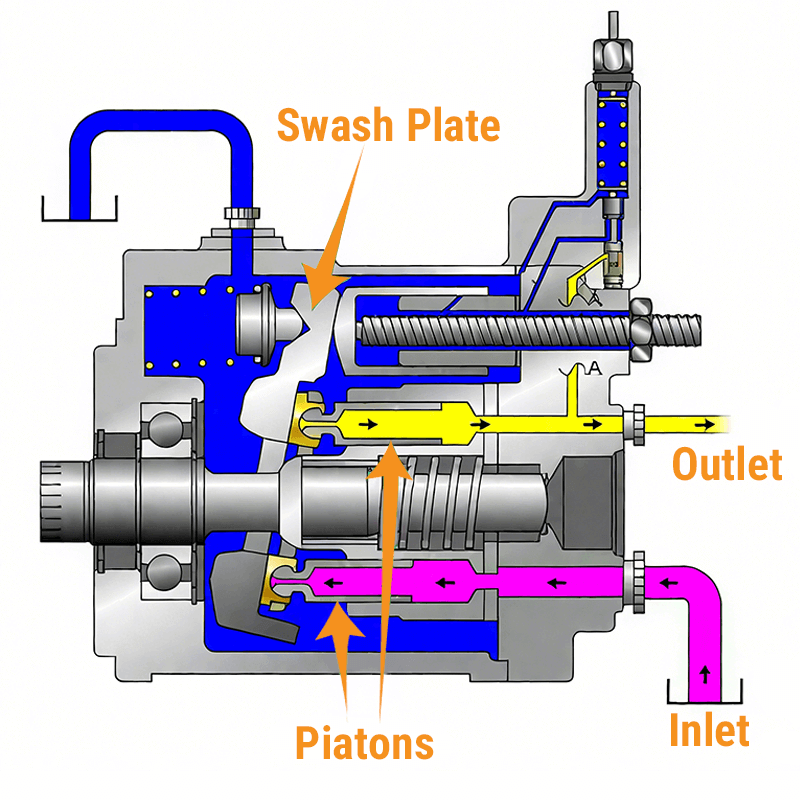

Piston pumps are the heavy lifters of the hydraulic world and are the most common type used for main systems in excavators, dozers, and cranes. They operate using a series of pistons that reciprocate inside a cylinder block.

- How it Works: The key component is an angled swashplate. As the engine’s driveshaft rotates the cylinder block, the pistons follow the angled surface of the stationary swashplate. This makes the pistons move back and forth, drawing fluid in one half and pushing it out the other.

- Variable Displacement: The angle of the swashplate can be changed. A steeper angle results in a longer piston stroke and more fluid flow. A nearly flat angle results in a very short stroke and minimal flow. This ability to vary the flow independently of engine speed makes piston pumps incredibly efficient. They only produce the flow needed for the job, saving fuel. Due to their close integration, the terms hydraulic pump and motor are often discussed together, as many hydrostatic drive systems utilize a variable piston pump to power a piston motor.

- Best Suited For: Piston pumps can generate extremely high pressures, making them essential for the main digging, lifting, and pushing functions of large construction equipment.

Hydraulic Pump Structures Used in Heavy Equipment

Different machines combine these pump types to create an optimized system. Here is a breakdown of typical configurations:

| Equipment Type | Main Pump Type | Auxiliary or Pilot Pump | Notes |

|---|---|---|---|

| Excavator | Variable Axial Piston Pump | Gear Pump (Pilot Pump) | Often uses a dual-pump system for combined flow and power management. |

| Dozer | Variable Piston Pump | Gear Pump | Employs load-sensing controls to match engine power to the load. |

| Wheel Loader | Fixed Displacement Gear Pump | Small Gear Pump or None | Prioritizes cost-effectiveness and reliability for medium-power tasks. |

| Crane | Variable Piston Pump | Gear Pump (Pilot Pump) | Requires very high pressure for lifting heavy loads safely. |

| Scissor Lift | Gear Pump or Small Piston Pump | None | Uses a simple |

Do Hydraulic Systems Need Maintenance?

Absolutely. A hydraulic system operates under extreme pressure and with the tightest tolerances. Proactive maintenance isn’t merely a recommendation — it stands as the very key to averting costly downtime and catastrophic failure. The best practices include:

- Regularly checking hydraulic fluid levels and quality.

- Replace hydraulic filters at manufacturer-recommended intervals.

- Inspecting hoses, fittings, and seals for leaks, cracks, or wear.

- Use the correct type and viscosity of hydraulic oil.

Over time, even with perfect maintenance, pistons, vanes, and gears will inevitably wear out. This wear gradually lowers pressure and slows machinery, a condition known as reduced volumetric efficiency. When you start to feel your machine losing power or becoming sluggish, it’s usually a clear sign of a hydraulic pump failure. In such a juncture, the holistic substitution of the hydraulic pump commonly represents the most dependable and economically judicious stratagem to reinstate the operational efficacy of the machine, concurrently precluding metallic detritus emanating from a deteriorating pump from inflicting detriment upon the residual system.

Summary

The hydraulic pump constantly moves oil to fuel your equipment’s power and longevity. Knowing how it works and its types helps you assess performance and detect issues early. By prioritizing proper maintenance and addressing issues early, you can make sure this essential part keeps driving your productivity for years. When replacement becomes necessary, FridayParts can provide reliable, compatible parts, letting you get back to work quickly and worry-free.